Chemical mechanical polishing solution of phase-change material composite abrasive and application thereof

A composite abrasive, chemical-mechanical technology, applied in the field of microelectronics, to achieve the effect of good surface quality, improved stability, and avoidance of residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

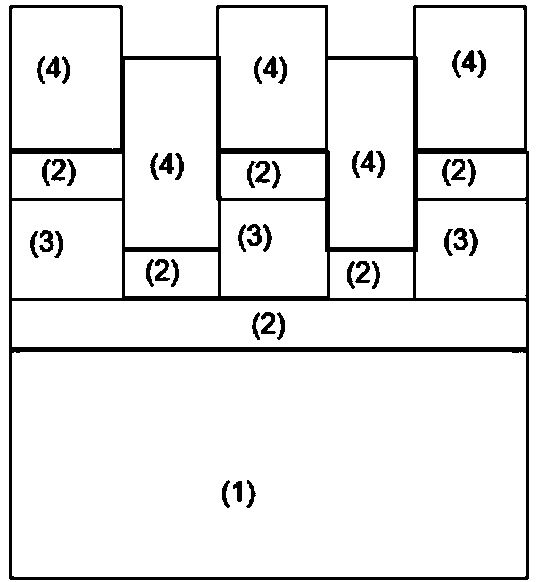

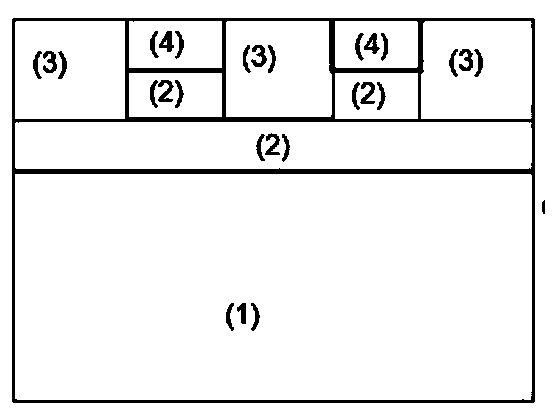

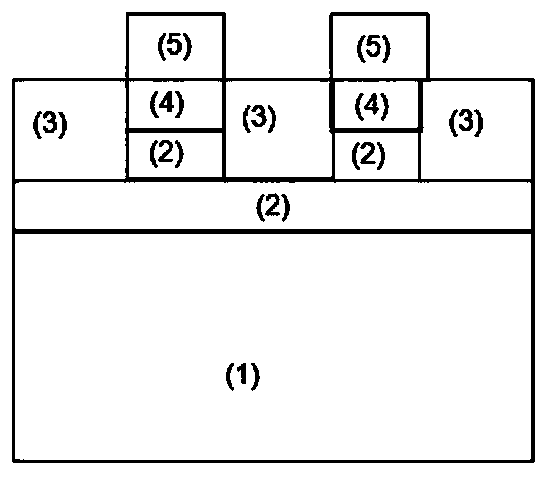

Method used

Image

Examples

Embodiment 1

[0023] The preparation of polishing liquid A: the polishing liquid contains 10wt% silicon oxide and cerium oxide polishing abrasive, the particle size is 30nm, add hydrogen peroxide 4.0wt%, potassium hydroxide 0.5wt% to adjust the pH to 8, sodium polyacrylate 0.1wt %, citric acid 0.05wt%, and the rest is deionized water.

Embodiment 2

[0025] Preparation of polishing liquid B: the polishing liquid contains 40wt% silicon oxide and cerium oxide polishing abrasives, the particle size is 20-80nm, adding 4.0wt% ferric chloride, 0.5wt% sodium hydroxide to adjust the pH to 9, hexadecane 0.1wt% trimethylammonium bromide, 0.05wt% acetic acid, and deionized water as the rest.

Embodiment 3-7

[0027]

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com