Stage equipment performance matching test and debugging system

A stage equipment and matching test technology, applied in the direction of test/monitoring control system, control/adjustment system, general control system, etc., can solve problems such as operation errors, difficult stage control, difficult operation, etc., to achieve intelligent control and management, good stage effects, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

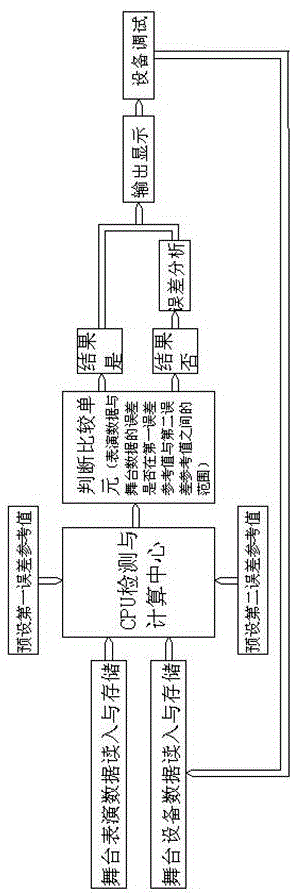

[0014] Such as figure 1 A stage equipment performance matching test and debugging system shown includes a CPU detection and calculation center, a judgment comparison unit, and an output display. The output terminal of the CPU detection and calculation center is connected to the input terminal of the judgment comparison unit, and the judgment comparison unit The output Connect the input terminal of the output display, the output terminal of the output display is connected to the input terminal of equipment debugging, and the input terminal of the CPU detection and calculation center is respectively connected to the stage performance data reading and storage and stage equipment data reading and storage.

[0015] In this embodiment, the input terminals of the CPU detection and calculation center are respectively connected to a preset first error reference value and a preset second error reference value, and the value of the preset first error reference value is smaller than the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com