A full-wave rectifier circuit and voltage converter

A full-wave rectification circuit and circuit technology, applied in the direction of conversion equipment without intermediate conversion to AC, etc., can solve the problems of affecting the efficiency of rectification circuits, complex control, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

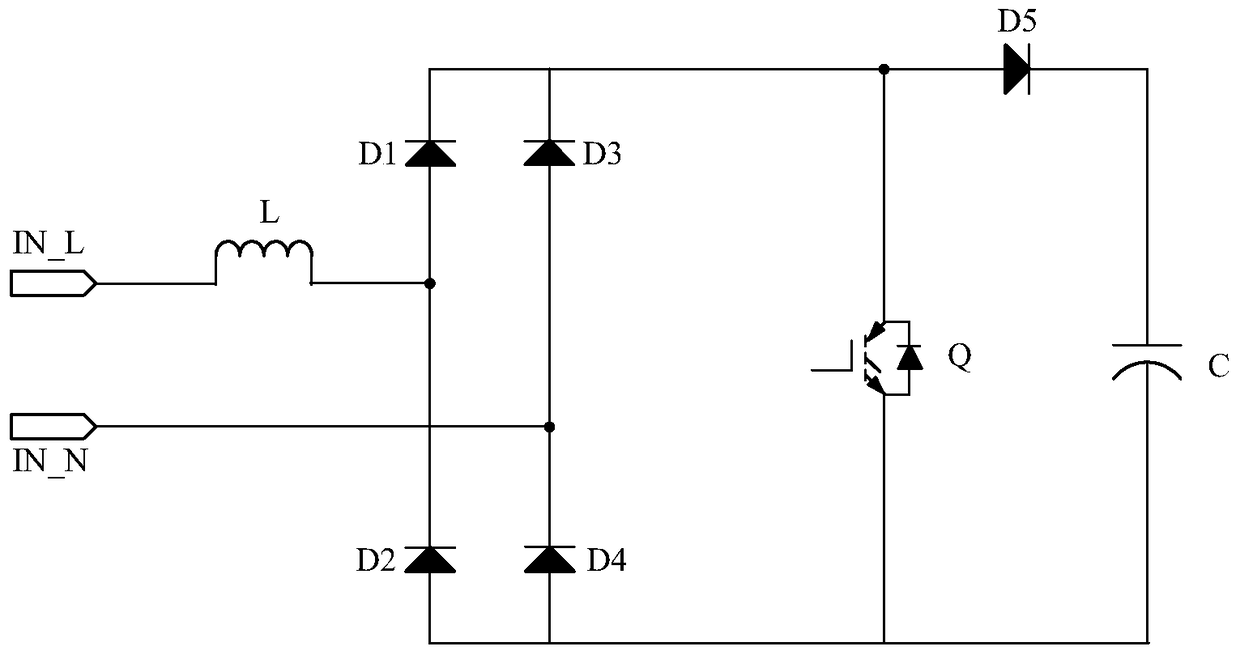

[0074] figure 2 Shown is the full-wave rectification circuit provided by Embodiment 1 of the present invention, including capacitor C, inductor L, MOS transistor Q, first rectifier diode D1, second rectifier diode D2, third rectifier diode D3, fourth rectifier diode D4 and Freewheeling diode D5, where:

[0075] The first rectifier diode D1 and the second rectifier diode D2 are connected in series to form the first branch, the third rectifier diode D3 and the fourth rectifier diode D4 are connected in series to form the second branch, and the first branch and the second branch are connected in parallel to form the third branch. The third branch is connected in series with the inductance L and the MOS transistor Q to form a circuit;

[0076] The terminal between the inductor L and the drain of the MOS transistor Q is connected to the anode of the freewheeling diode D5, and the cathode of the freewheeling diode D5 is connected to the anode of the capacitor C;

[0077] The term...

Embodiment 2

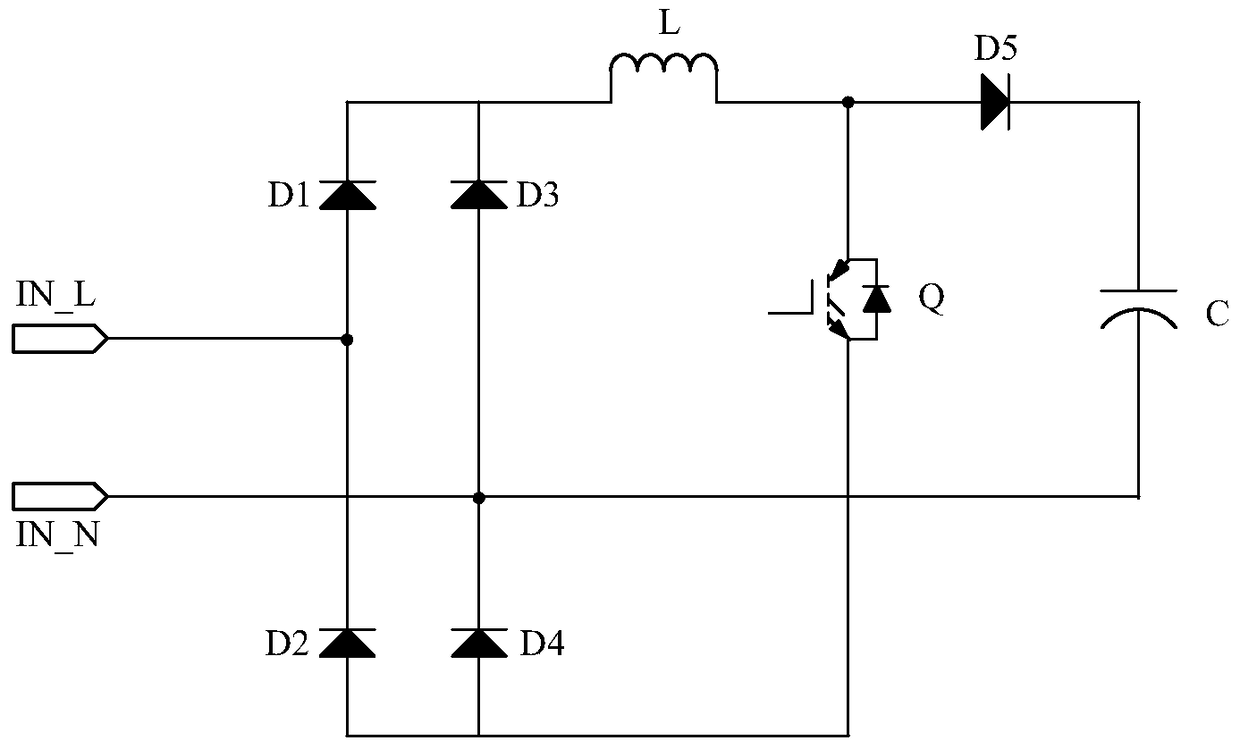

[0086] image 3 Shown is the full-wave rectification circuit provided by Embodiment 2 of the present invention, including capacitor C, inductor L, MOS transistor Q, first rectifier diode D1, second rectifier diode D2, third rectifier diode D3, fourth rectifier diode D4 and Freewheeling diode D5, where:

[0087] The first rectifier diode D1 and the second rectifier diode D2 are connected in series to form the first branch, the third rectifier diode D3 and the fourth rectifier diode D4 are connected in series to form the second branch, and the first branch and the second branch are connected in parallel to form the third branch. The third branch is connected in series with the MOS tube Q and the inductor L to form a loop;

[0088] The terminal between the inductor L and the source of the MOS transistor Q is connected to the cathode of the freewheeling diode D5, and the anode of the freewheeling diode D5 is connected to the negative pole of the capacitor C;

[0089]The terminal...

Embodiment 3

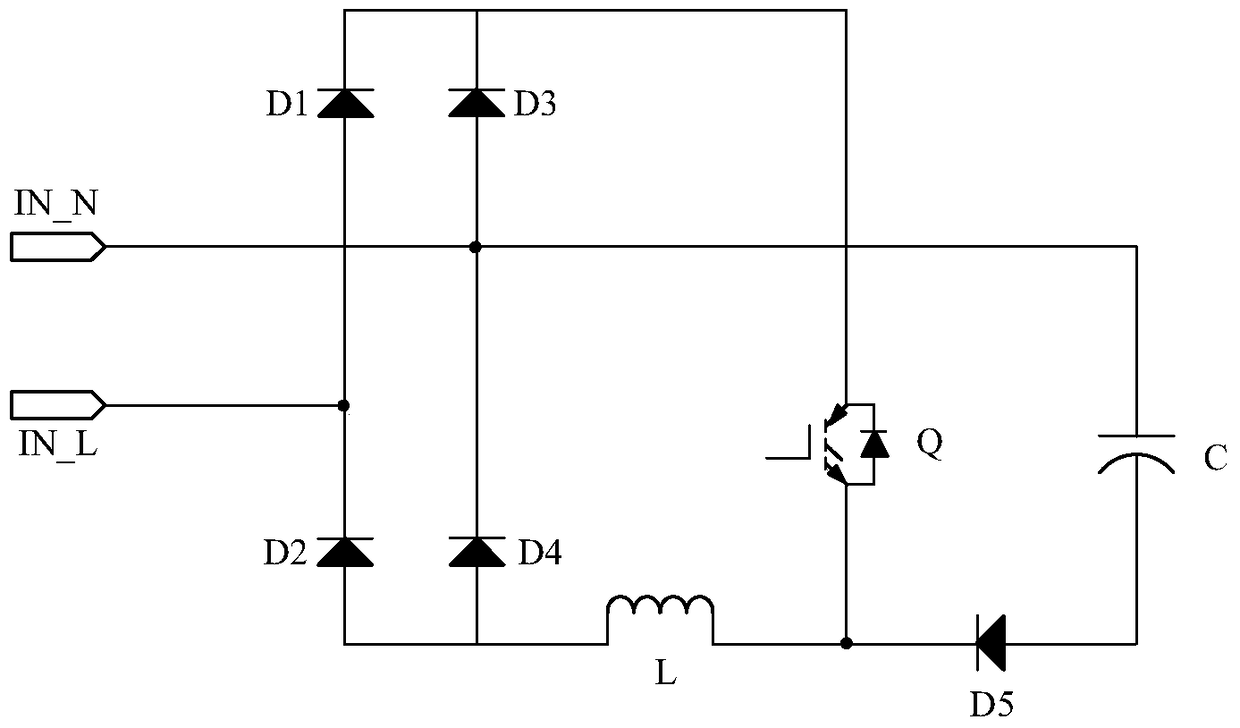

[0098] Figure 4 Shown is the full-wave rectification circuit provided by Embodiment 3 of the present invention, compared with that provided by Embodiment 1 of the present invention figure 2 In the full-wave rectification circuit shown, a soft-start unit is added on the live wire terminal IN_L side of the AC input power supply, and the terminal between the first rectifier diode D1 and the second rectifier diode D2 in the first branch is connected to the output of the soft-start unit Terminal, the input terminal of the soft start unit is used as the fire wire terminal IN_L of the AC input power supply.

[0099] The soft-start unit may specifically include a parallel current-limiting diode D6 and a switch S; one end corresponding to the cathode of the current-limiting diode D6 in the soft-start unit is used as the input end of the soft-start unit, and the anode of the current-limiting diode D6 in the soft-start unit corresponds to One end of the soft start unit as the output. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com