Traction truck with loading crane

A vehicle-mounted lifting and tractor technology, applied in the field of vehicles, can solve problems such as work efficiency impact and accidents, and achieve the effects of increasing counterweight, increasing counterweight, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

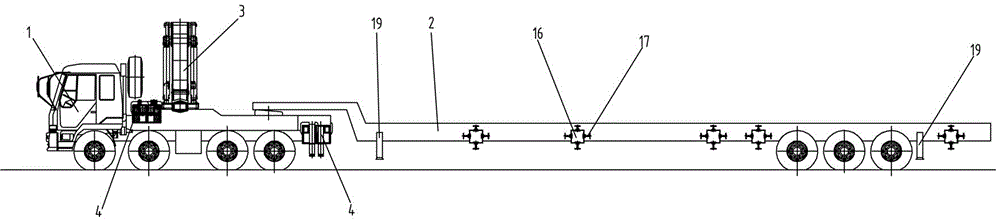

[0018] refer to figure 1 , the traction vehicle lifting transport vehicle of the present invention includes a tractor 1, a trailer 2, and a crane (hoist) machine 3 installed on the tractor.

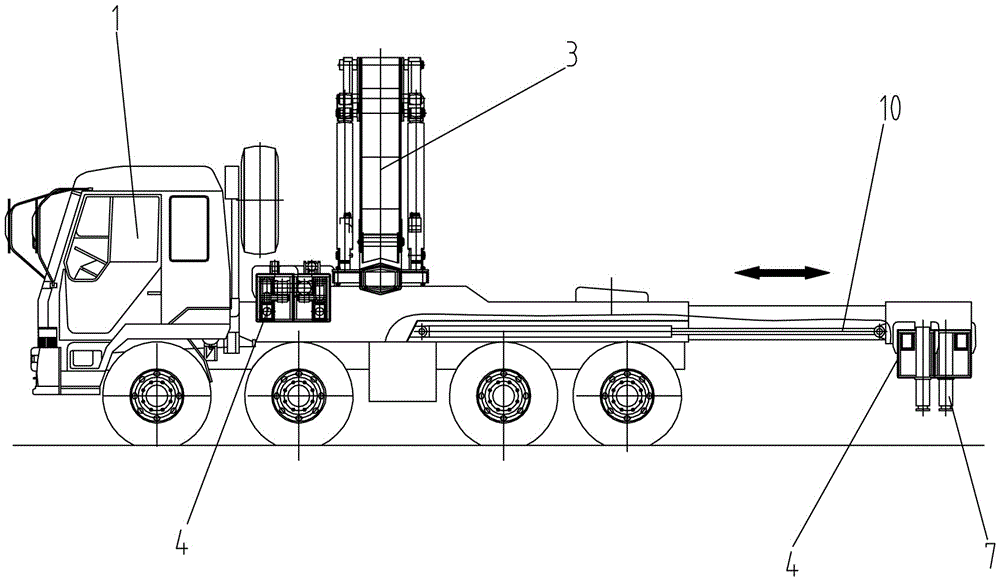

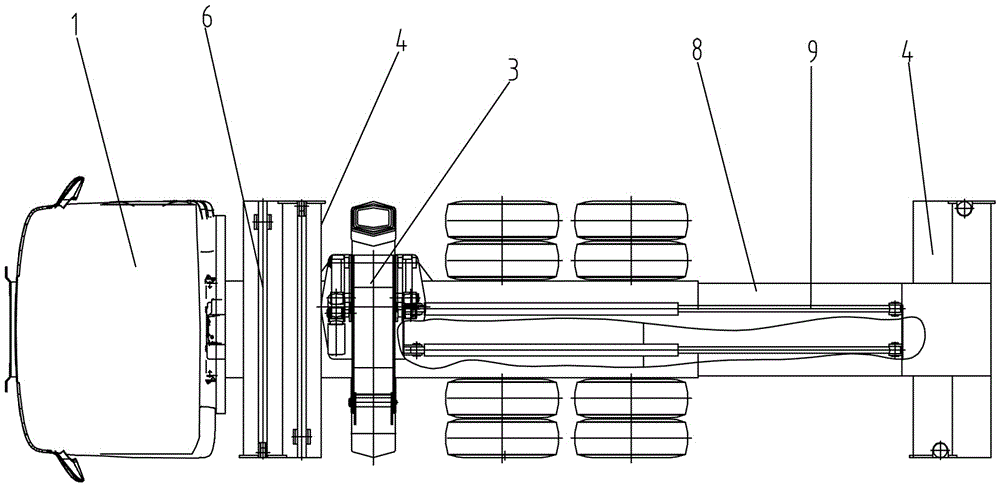

[0019] Refer to 2, image 3 , Figure 4 , two groups of beams 4 fixed on the front and rear of the chassis of the tractor, each group of two beam boxes can respectively protrude to the left and right lifting load beams 5, between the load beam 5 and the beam box 4 An oil cylinder 6 for controlling the extension and retraction of the load beam, and a lifting leg 7 hinged at the outer end of the load beam 5 . A longitudinal telescopic beam 8 is arranged at the rear end of the chassis of the tractor to cooperate with the chassis or a socket member fixed on the chassis. The beam box 4 at the rear of the tractor is fixed on the outer end of the telescopic beam 8. Install telescopic beam control oil cylinder 9.

[0020] refer to Figure 4 , Figure 5 , Figure 6 1. A tenon 10 protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com