Forming delay mechanism for die

A technology of time-delay mechanism and mold, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of short forming time, too late stress release, no consideration of forming time, etc., and achieve reliable work, good forming effect, and extended Effect of forming action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

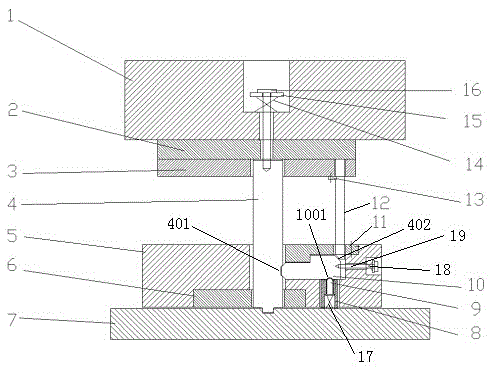

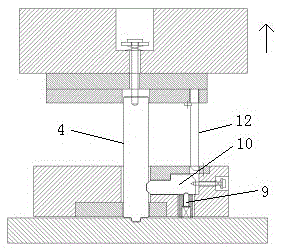

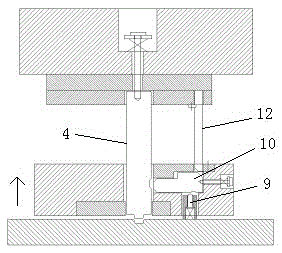

[0013] Such as figure 1 As shown, the forming delay mechanism of the mold provided by the present invention includes an upper mold part, a discharge part and a die plate, and the upper mold part includes an upper backing plate 2 on which an upper mold base 1 is located and a punch fixing Plate 3, the upper mold part is provided with a punch 4 and a vertical bar 12 parallel to the punch 4, the punch 4 passes through the attachment 15 placed in the upper die base 1, the return spring 14 and passes through the upper backing plate 2 and the screw 16 fixed on the upper mold base 1 is hoisted in the punch fixing plate 3, and the side of the punch 4 is provided with a groove 401; the vertical rod 12 is installed on the punch fixing plate 3 through the vertical rod cover plate 13 On the top, the head of the vertical rod 12 is wedge-shaped; the discharge part includes a discharge plate seat 5, a small discharge plate 6 and a push rod cover 11, and the discharge part is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com