Tool bit blank and synthetic process thereof and synthetic mold thereof and tool bit production method

A technology of cutter heads and blanks, which is applied in the field of composite molds and cutter head blanks, can solve the problems of high processing cost of composite cutter heads, high cost of mold containers, and difficulty in adding materials, so as to speed up production, reduce dependence, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

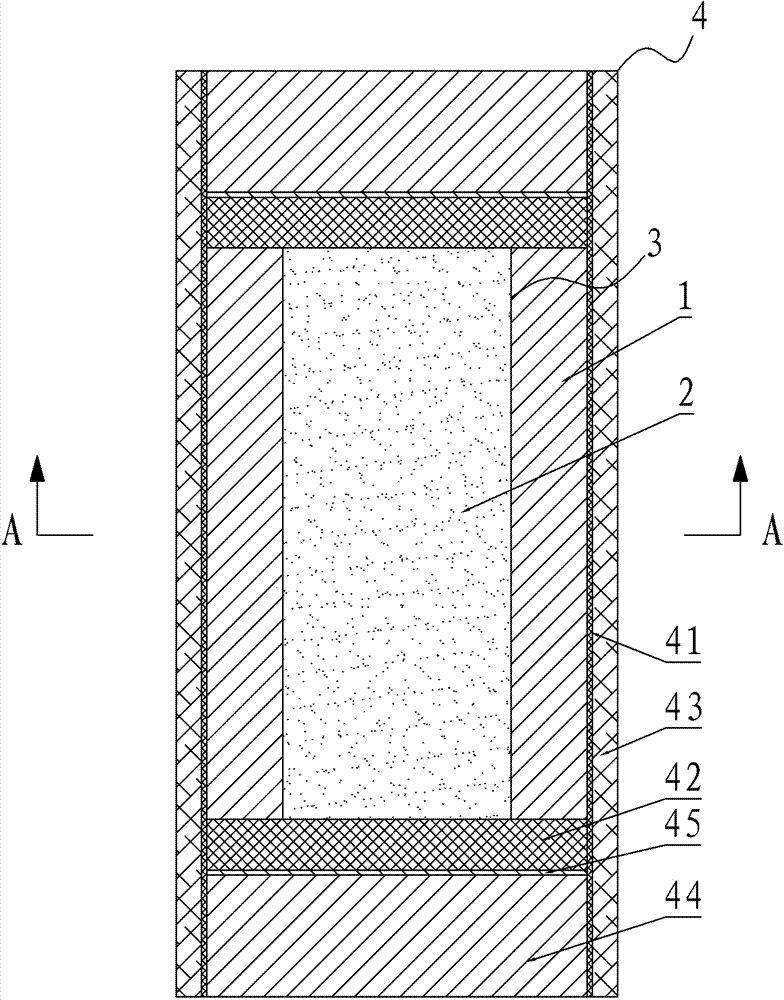

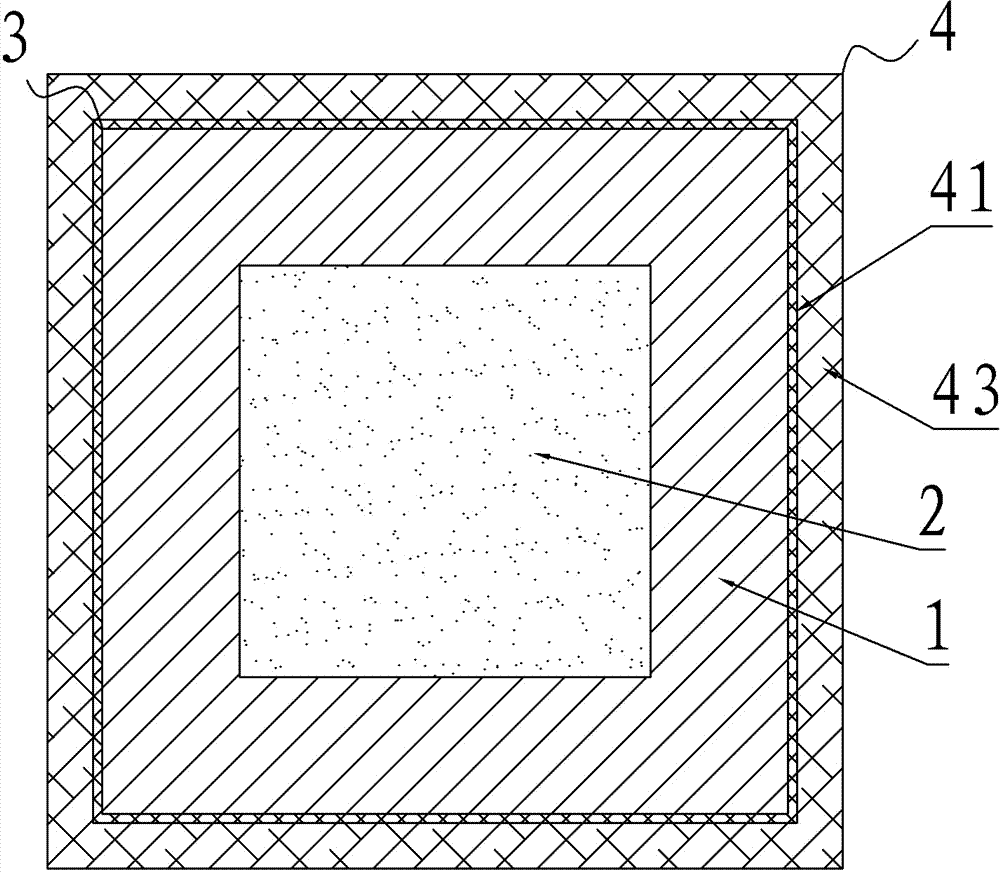

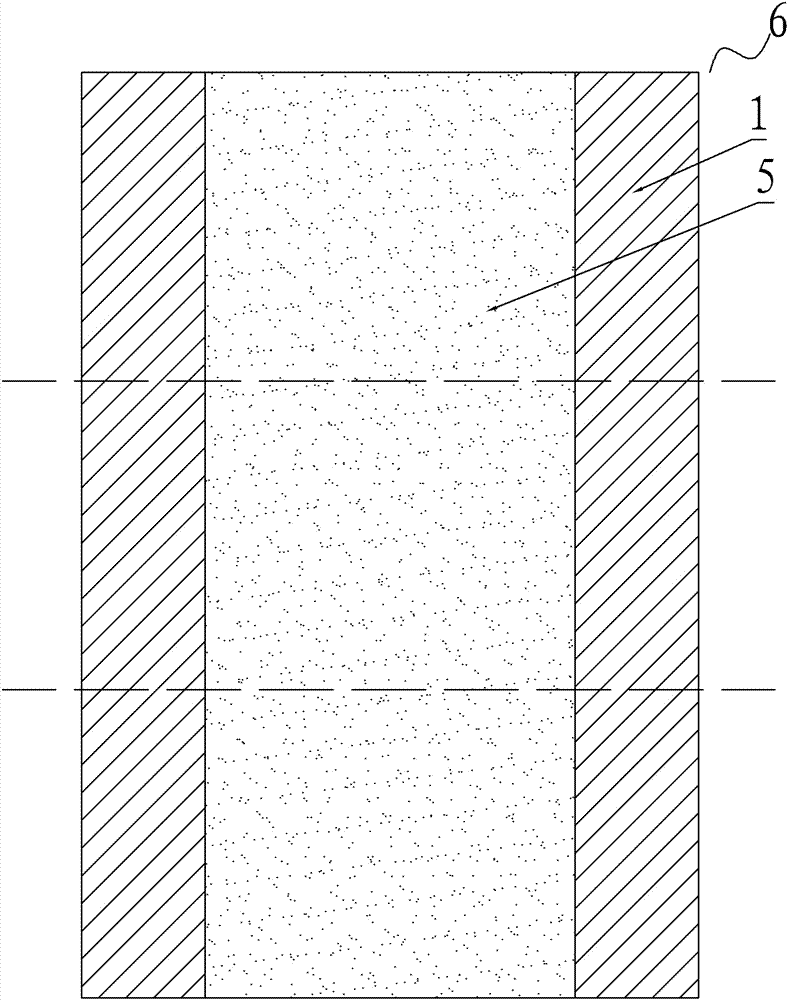

[0033] The embodiment of the cutter head blank of the present invention: as Figure 1 to Figure 4 As shown, the cutter head blank 6 includes a sleeve body 1 made of hard alloy material and a cylinder 5 made of polycrystalline cubic boron nitride material, the sleeve body 1 is a square tube-shaped square sleeve, and the The column body 5 is a square column body that fits and complements each other and is inserted in the inner hole of the casing, and the column body 5 is sintered and fixed on the inner peripheral surface of the casing body 1 .

[0034] When the cutter head blank 6 of the present embodiment is manufactured, the cutter head blank is synthesized through the following steps:

[0035] Step 1: After sealing the lower end opening of the casing 1 made of hard alloy material, fill the casing 1 with polycrystalline cubic boron nitride dust 2 until the polycrystalline cubic boron nitride dust 2 and the casing 1 After the end faces are flush, the upper opening of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com