Implementation method for seamless splicing point-to-point display of liquid crystal screens

An implementation method, a technology of seamless splicing, which is applied to instruments, identification devices, etc., can solve the problems of small observation range, inability to achieve display effect, and increased viewing angle influence, achieve low cost, and achieve seamless large-screen display. The effect of the point-to-point display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

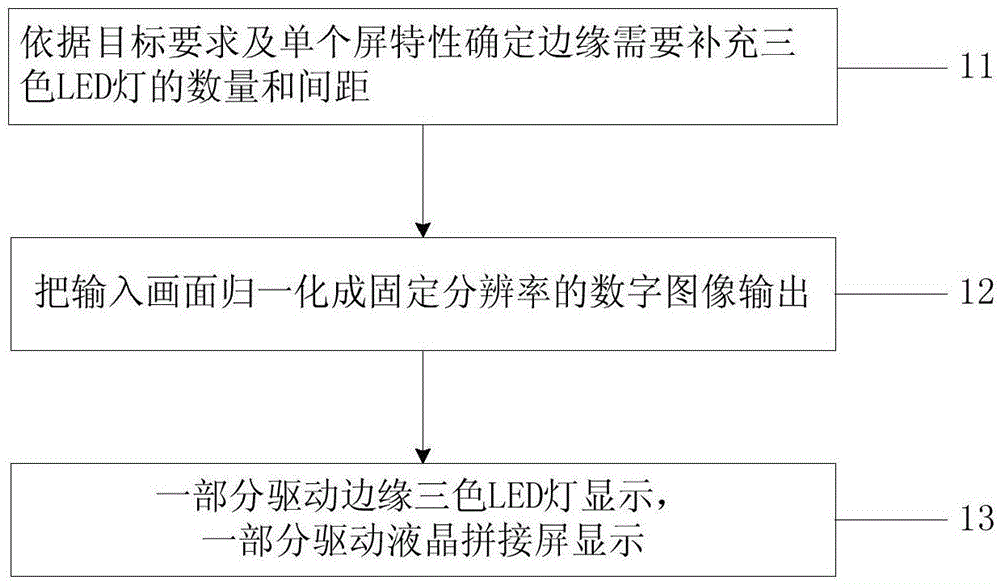

[0023] as attached figure 1 As shown, the method for realizing the seamless splicing point-to-point display of the liquid crystal screen of the present invention comprises the following steps:

[0024] 11) Determine the number and spacing of three-color LED lights that need to be supplemented on the edge according to the target requirements and the characteristics of a single screen;

[0025] The goal requirement is: to achieve the point-to-point display effect after splicing.

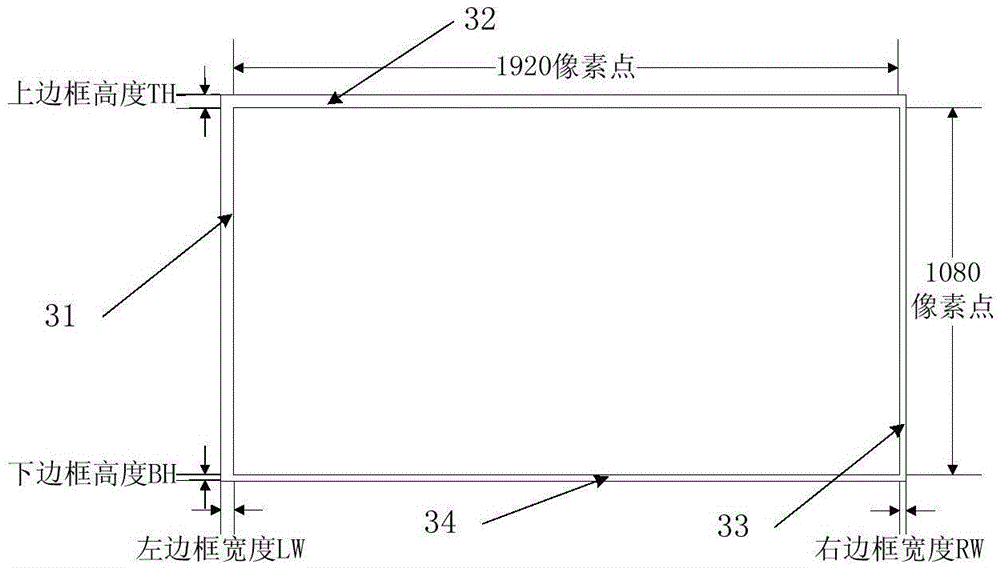

[0026] The characteristics of a single screen are: the size of the liquid crystal point, the size of the frame, etc.

[0027] 12) Normalize the input picture into a fixed resolution digital image output;

[0028] 13) A part drives the edge three-color LED light display, and a part drives the LCD splicing screen display.

[0029] For a specific embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com