A kind of manufacturing method of 3D lens, 3D lens and 3D glasses

The technology of a 3D lens and a manufacturing method, which is applied in the field of 3D video, can solve the problems that affect the appearance of the product and the black edge of the lens, and achieve the effect of avoiding the black edge, consistent light transmittance, and eliminating the black edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

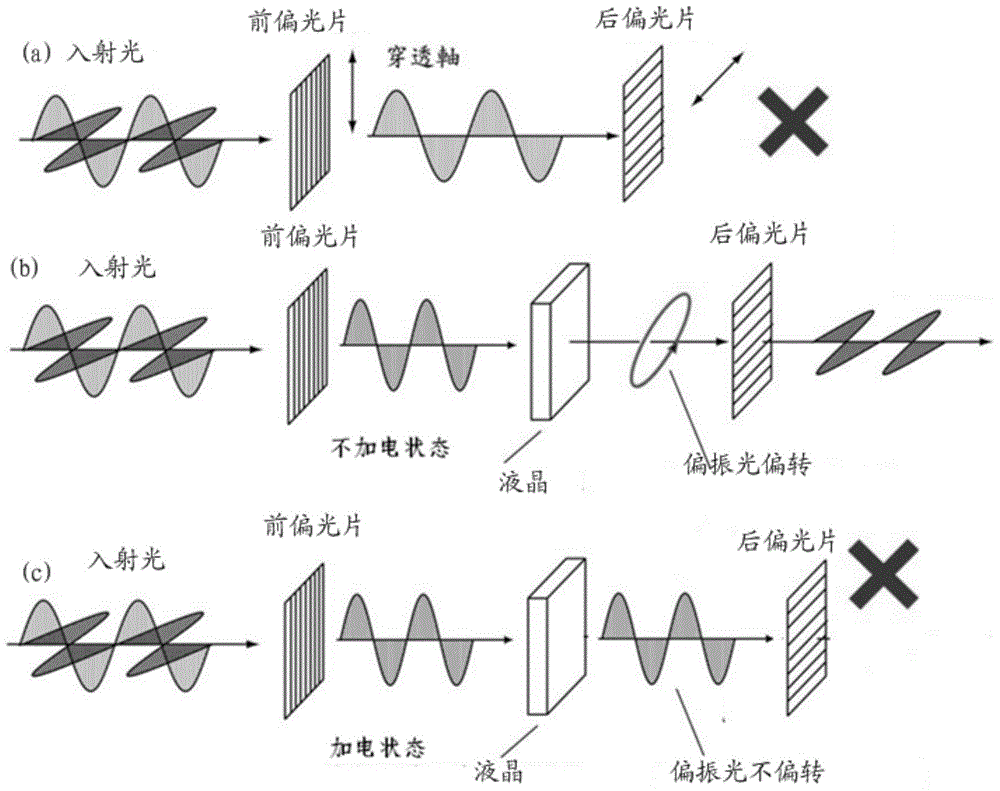

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

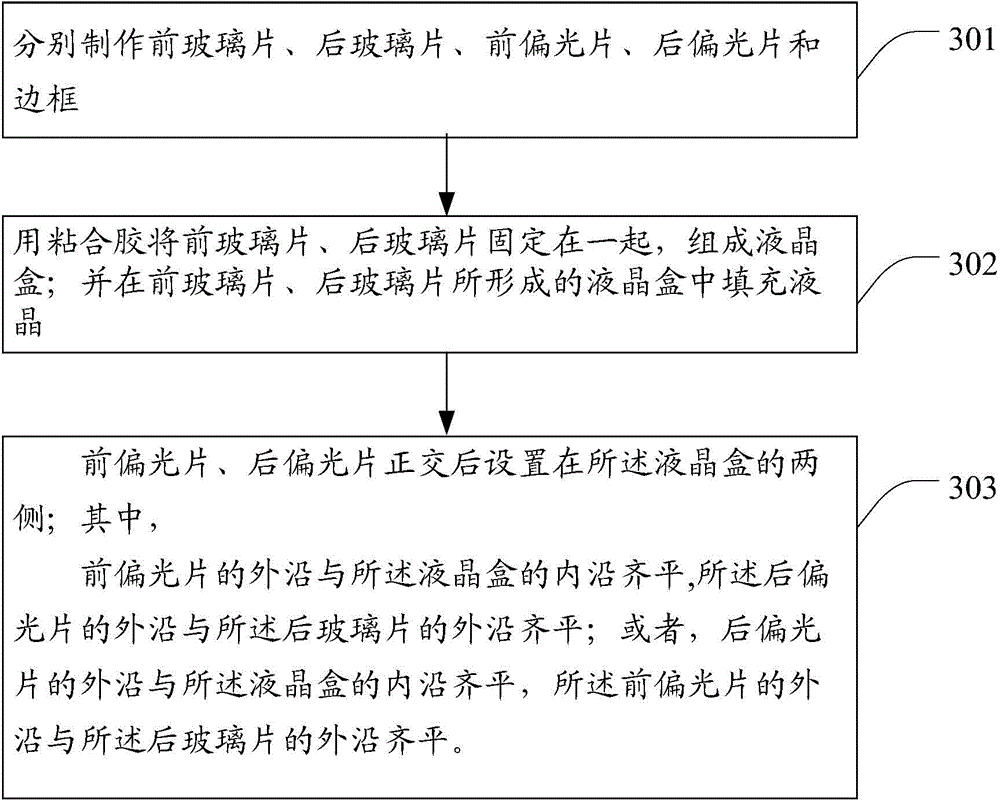

[0042] image 3 Is a flow chart of a 3D lens manufacturing method in the present invention, such as Figure 4 As shown, the method includes the following steps:

[0043] In step 301, the front glass sheet, the rear glass sheet, the front polarizer, and the rear polarizer are respectively produced;

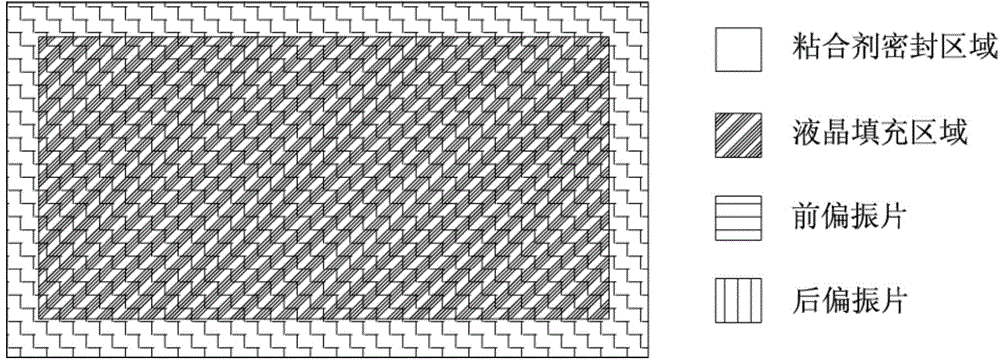

[0044] Step 302: Use adhesive glue to fix the front glass sheet and the back glass sheet together to form a liquid crystal cell; and fill the liquid crystal cell formed by the front glass sheet and the back glass sheet;

[0045] Step 303, the front polarizer and the rear polarizer are orthogonally arranged on both sides of the liquid crystal cell; wherein the front polarizer is arranged on one side of the front glass sheet, and the rear polarizer is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com