Balanced bearing adjustment mechanism for sliding door of furniture

A technology of adjusting mechanism and sliding door, which is applied to switches with brakes, door/window fittings, building structures, etc. User needs and other issues, to achieve the effect of improving the sliding opening and closing effect, eliminating installation difficulties, and smooth sliding opening and closing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

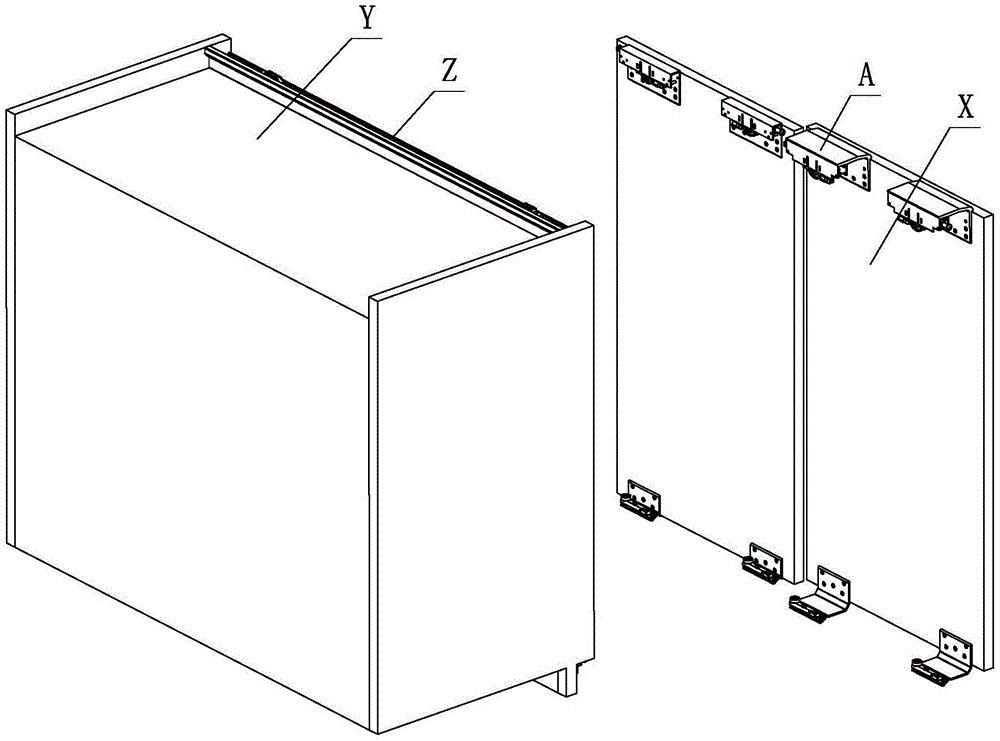

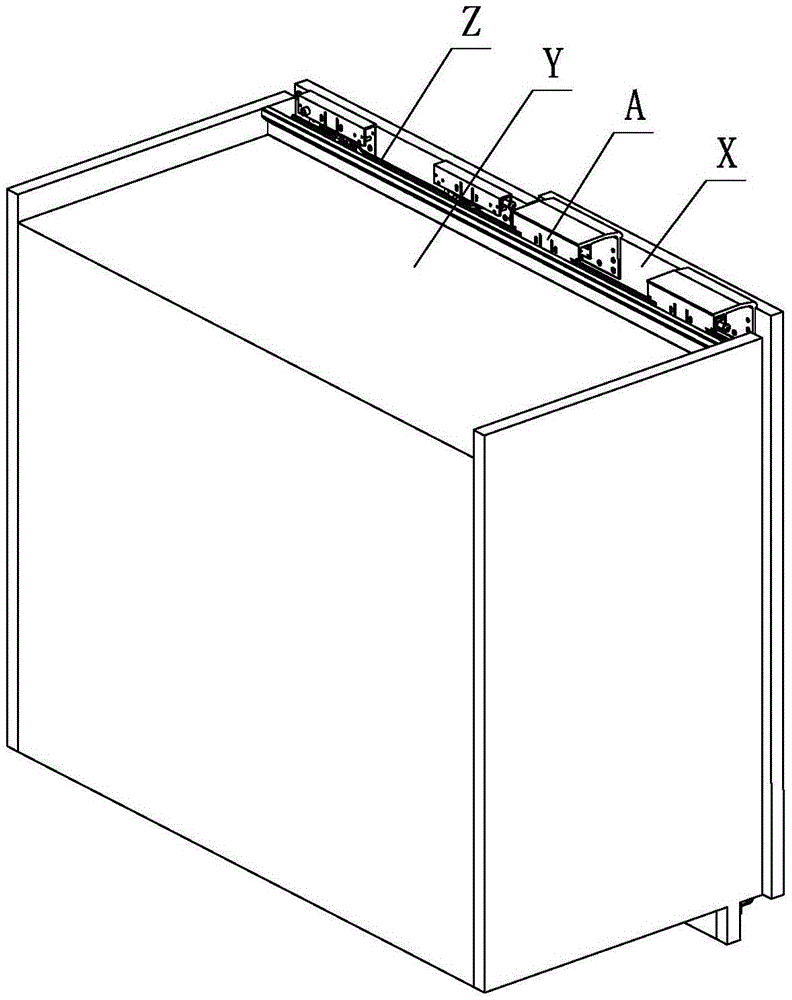

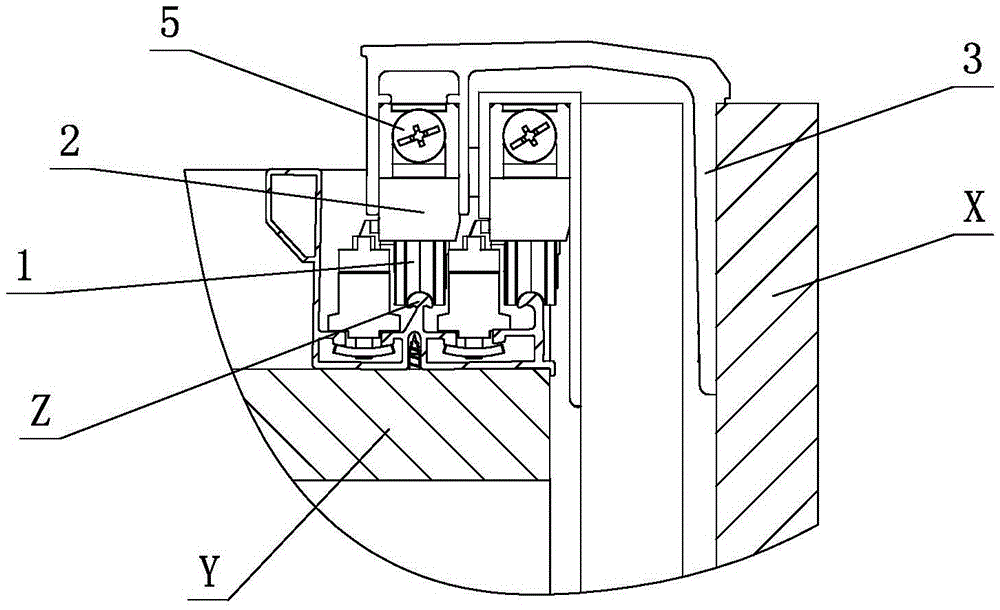

[0032] see Figure 1-Figure 7 The balance bearing adjustment mechanism of the furniture sliding door includes an adjustment device A, the adjustment device A includes a rotating element 1, a supporting element 2 and a bearing element 3, the rotating element 1 is positioned and rotated on the supporting element 2, and the supporting element 2 is slidably arranged on the bearing On the element 3, the adjusting device A also includes an actuating element 4 and an adjusting element 5, the actuating element 4 is slidably arranged on the bearing element 3, and at least two inclined parts 4.1 are arranged at intervals, and the supporting element 2 is arranged corresponding to the inclined parts 4.1 There are a considerable number of inclined fittings 2.1 through which the actuating element 4 interacts with the inclined fittings 2.1 of the support element 2, and the adjusting element 5 is positioned and rotated on the carrier element 3 and interacts with the actuating element 4; A too...

no. 2 example

[0045] see Figure 8-Figure 10 , the balance bearing adjustment mechanism of the furniture sliding door is different from the first embodiment in that: the adjustment element 5 is an eccentric disk, the bearing element 3 is provided with an assembly hole 3.3 corresponding to the eccentric disk, and the actuating element 4 is provided with a corresponding eccentric disk. The eccentric action part 4.3, one end of the eccentric disk is provided with an adjustment action part 5.1, the middle part is positioned and rotated on the assembly hole 3.3 of the bearing element 3, and the other end is provided with an eccentric part 5.2 which interacts with the eccentric action part 4.3 of the actuating element 4, through the tool Or manually adjust the action part 5.1, the eccentric disk is positioned and rotated, and the actuating element 4 is driven to slide laterally on the carrier element 3 through the interaction between the eccentric part 5.2 and the eccentric action part 4.3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com