A method of automatic push clamping of an arc -shaped grafting clip

A grafting clip and arc-shaped technology, which is applied in the field of automatic push-clamping of arc-shaped grafting clips, can solve the problem of low degree of automation, and achieve the effects of reducing labor intensity, low cost, and improving the success rate of grafting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment, further illustrate the present invention.

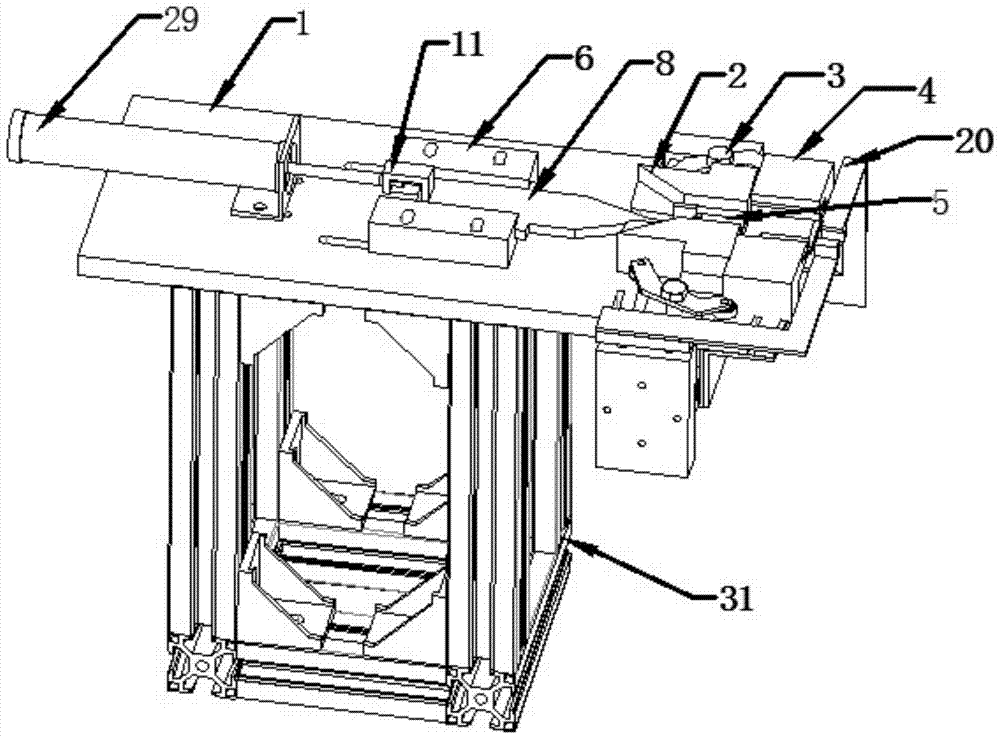

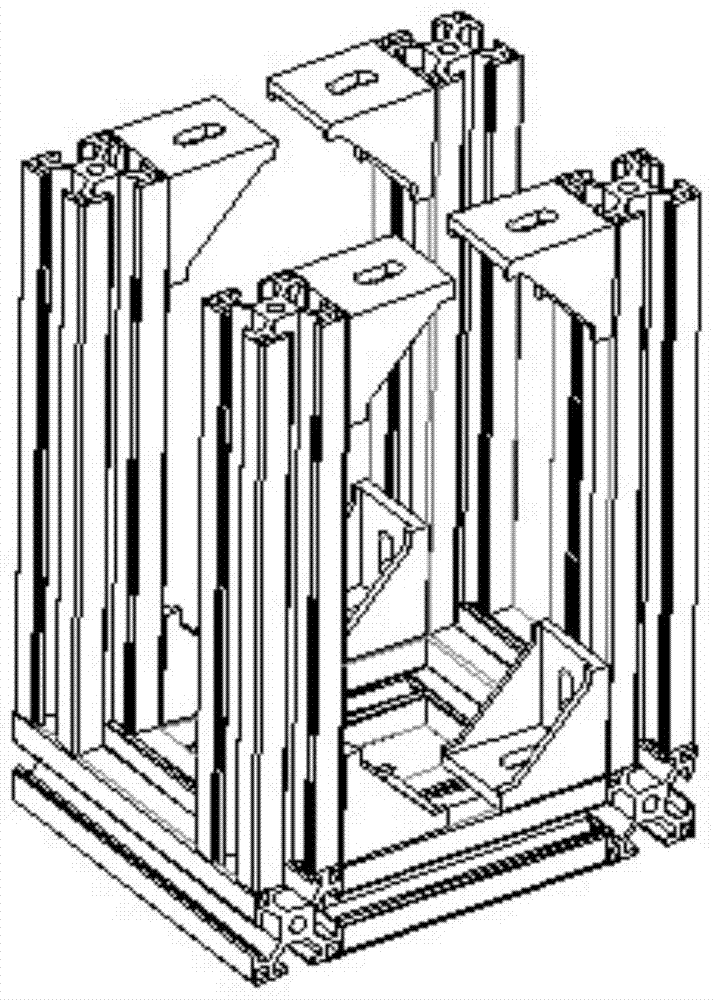

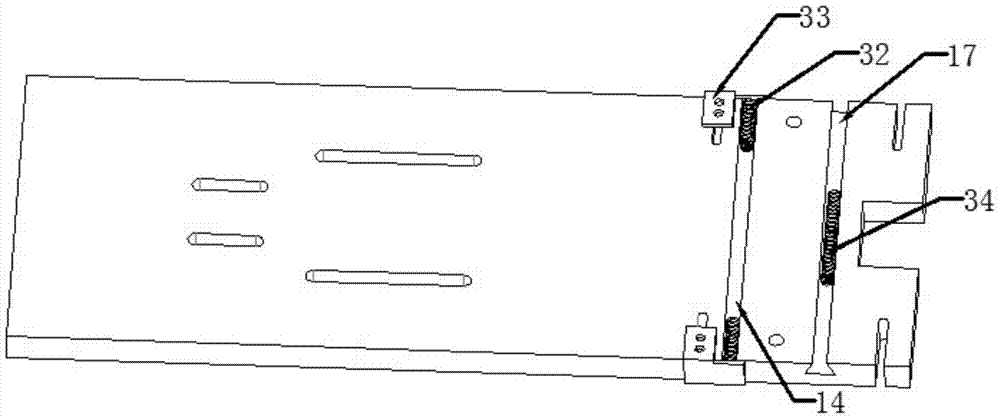

[0028] See attached Figure 1-12 , the present invention includes a base 1, on which a push rod assembly is arranged, one end of the push rod assembly is provided with a push rod mechanism that drives the push rod assembly to move, and the other end of the push rod assembly is provided with a Two sliding blocks 2 that slide longitudinally on the base, one side of each sliding block 2 is in contact with one end of the corner assembly that transmits the force, and the other end of each corner assembly is in contact with a guide that can slide longitudinally along the base 1 Groove block 4 contacts, and one end of described guide groove block 4 is provided with fixed seedling assembly 20, and the outside of two described slide blocks 2 is provided with reset mechanism one, is provided with reset mechanism two between two described guide groove blocks 4, A channel 5 for the entry and exit of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com