LED lamp

A technology of LED lamps and LED tubes, which is applied in the field of lighting, can solve problems such as limited light-emitting area, and achieve the effects of saving costs and resources, avoiding glare, and improving light control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

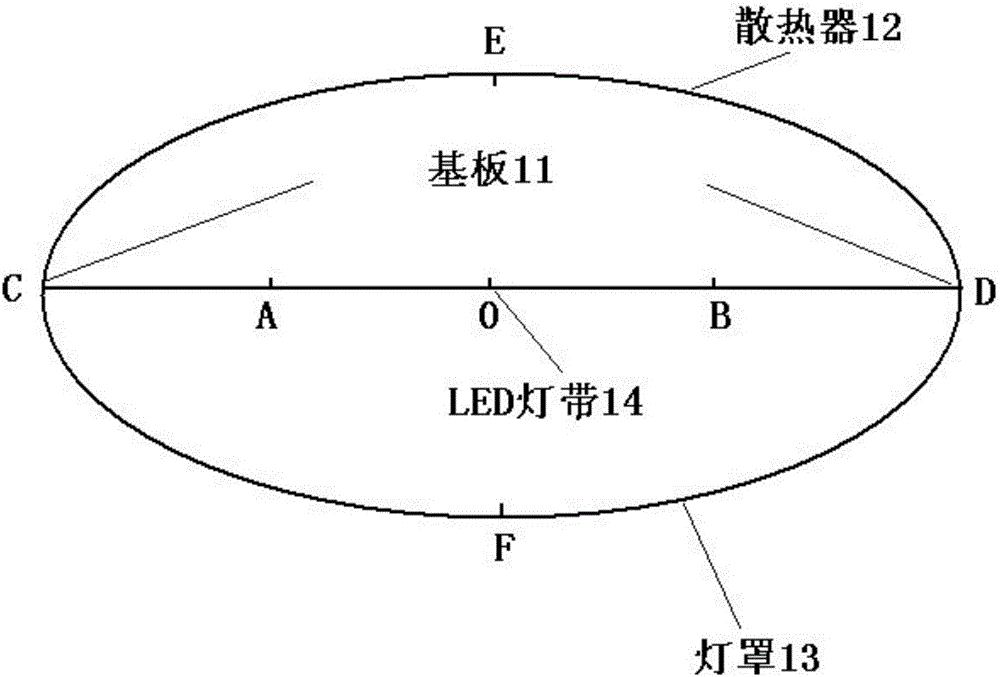

Embodiment 1

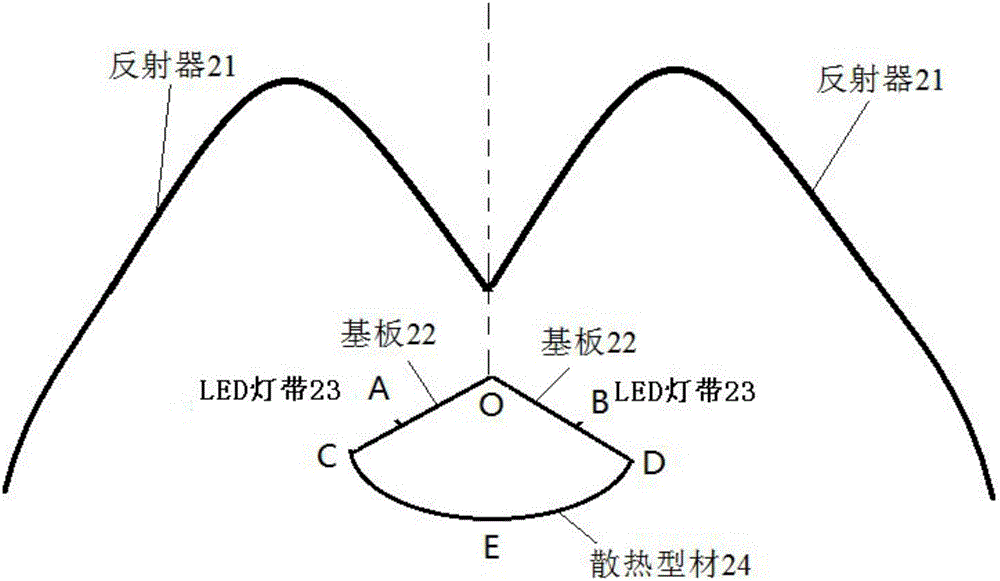

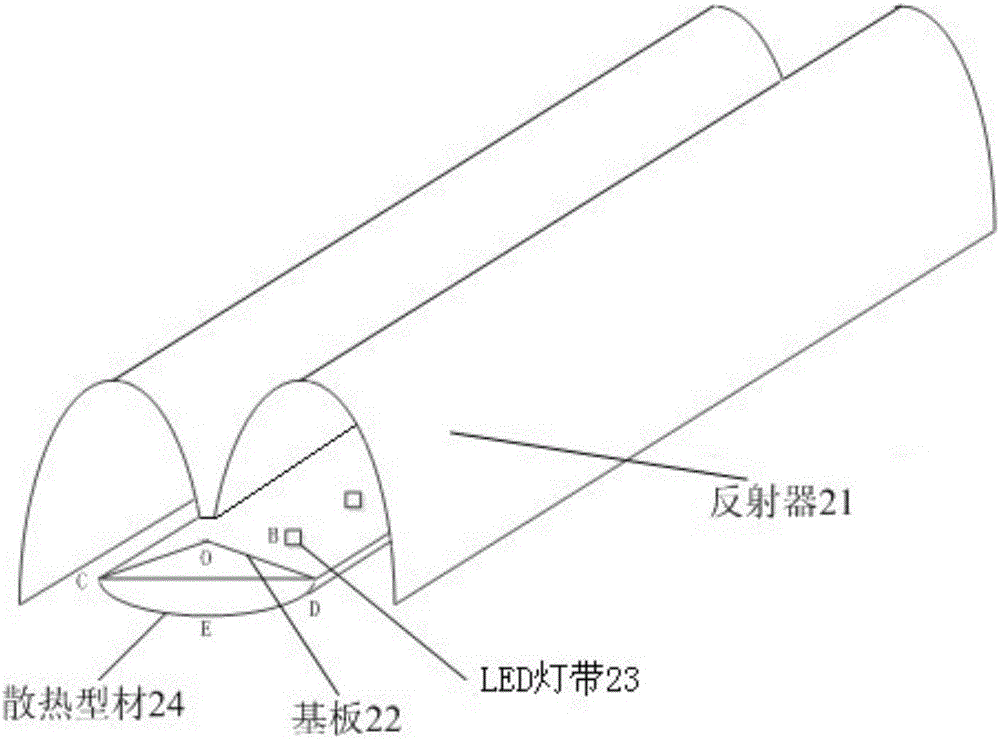

[0041] Such as Figure 2-7 As shown, according to the embodiment of the present application, an LED lamp is provided, including: an LED lamp housing 25 , an LED lamp tube and a reflector 21 .

[0042] LED light tube

[0043] Such as Figure 2-7 As shown, the LED light tube further includes: a substrate 22 represented by CO and DO, an LED light strip 23 represented by points A and B, and the substrate 22 has along the extending direction of the LED light tube An extended structure (i.e., image 3 The part of COD along the extension direction of reflector 21), the extension structure has a triangular or V-shaped protrusion (the part shown by point COD), the bottom surface of the extension structure has a planar structure, and the LED The light strip 23 is attached to the slopes on both sides of the protrusion (that is, the slope shown by CO and the slope shown by DO) to form two light-emitting surfaces, and the light-emitting surface formed by the combination of the two lig...

Embodiment 2

[0055] Such as Figure 8-13 As shown, the present application proposes another LED lamp, including: an LED lamp housing 45 , an LED lamp tube and a reflector 41 .

[0056] LED light tube

[0057] The LED light tube further includes: a base plate 42 (position between C and D) and an LED strip 43 (position between A and B), the base plate 42 has a planar structure, and the LED strip 43 is fixed on Two sides of the central axis of the substrate 42 along the extension direction of the lamp form two light-emitting surfaces (CO and DO form two light-emitting surfaces). Since the LED light strips of the existing LED light tubes are installed directly perpendicular to the substrate plane, in order to save resources and make the best use of the LED light strip’s luminous effect, the LED light strips are arranged on two light-emitting surfaces, that is, the LED The light strips are fixed on both sides of the central axis of the substrate along the extension direction of the lamp so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com