Bottle cap enabling bottle body to be placed invertedly

A bottle body and bottle cap technology, applied in the field of bottle cap optimization technology, can solve the problems of small bottle cap section, insufficient stability, easy to be knocked down, etc., and achieve the effect of convenient use, rapid combination and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

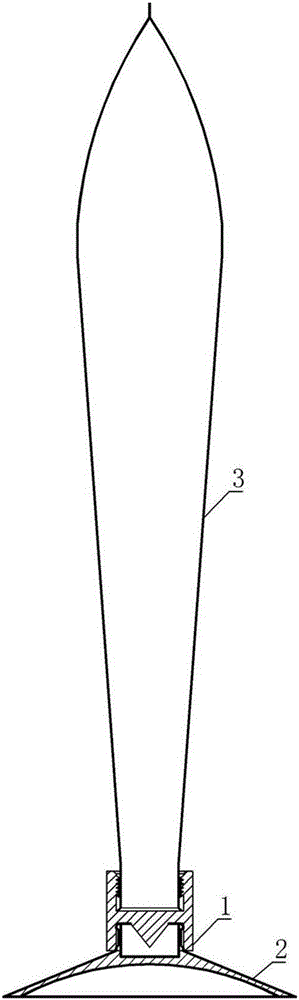

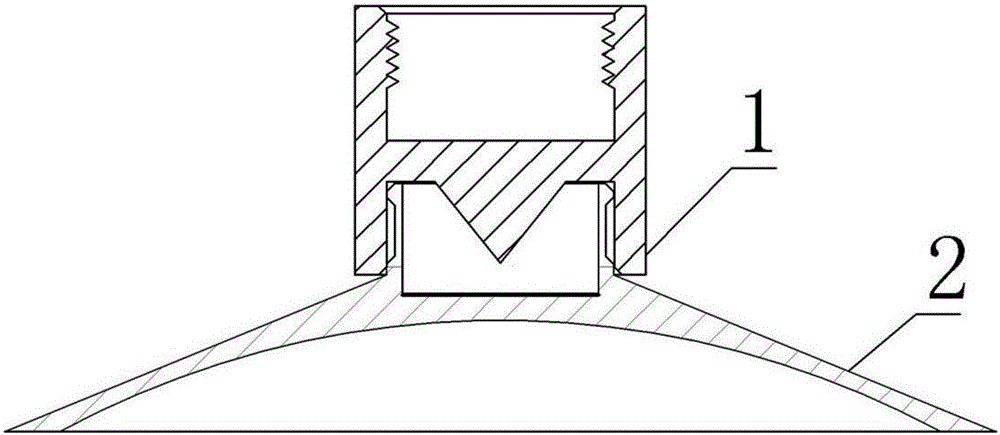

[0020] like figure 1 , figure 2 and image 3 As shown, the bottle cap that enables the bottle body to be stored upside down is composed of a cork 1 and a suction cup 2. When in use, screw the cork 1 on the mouth of the bottle body 3, place the suction cup on the table, and put the bottle The plug is inserted into the suction cup, and the bottle body can be placed upside down through the suction cup.

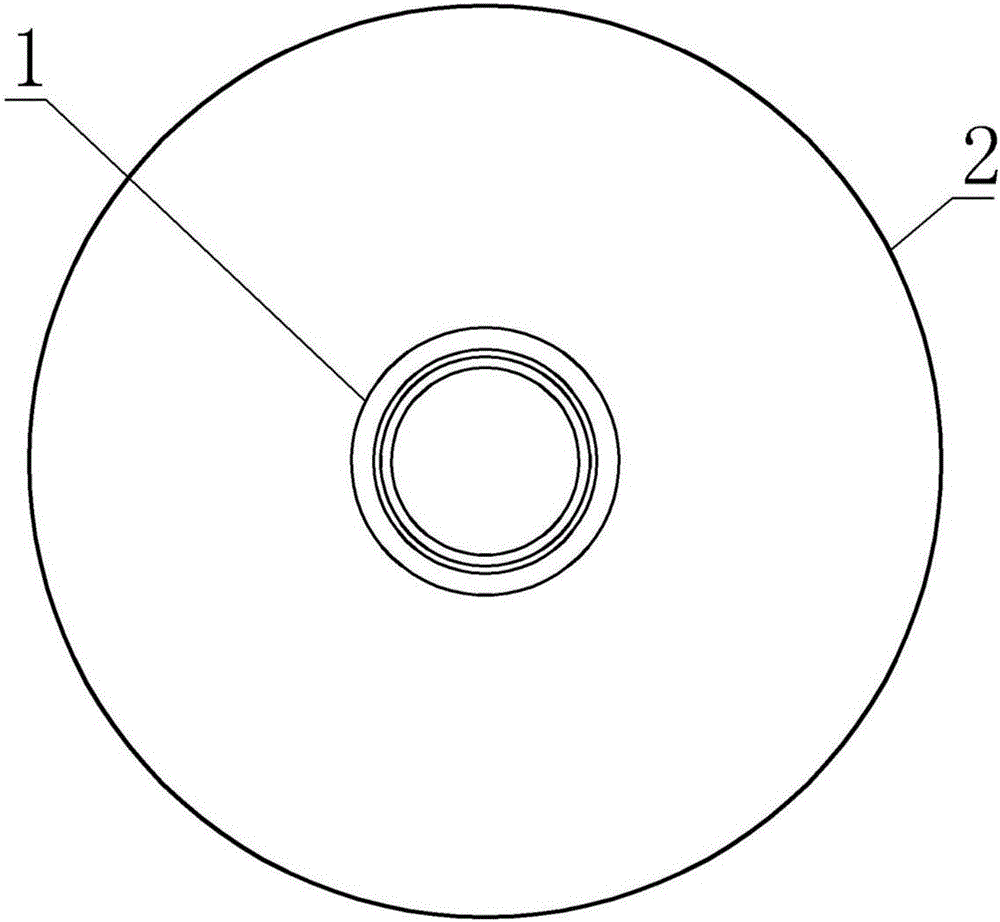

[0021] like Image 6 and Figure 7 As shown, the suction cup 2 is mainly composed of a plunger 21 and a disk surface 22; the disk surface 22 is disc-shaped, the diameter of the disk surface is greater than the diameter of the plunger 21, and the cut surface of the disk surface is arc-shaped; the plunger 21 is Hollow cylinder, the plunger 21 is placed on the outer wall of the arc top of the disk 22; the two ends of the outer wall of the plunger 21 are respectively provided with an upper flange 211 and a lower flange 212, forming a surrounding column between the upper flange a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com