A shaft sub-assembly of a light type conversion drive device and its application

A technology of driving device and conversion device, applied in signal device, optical signal, transportation and packaging, etc., can solve the problem of high noise of optical type conversion mechanism, improve service life and reliability, reduce mechanical friction, and rotate flexibly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

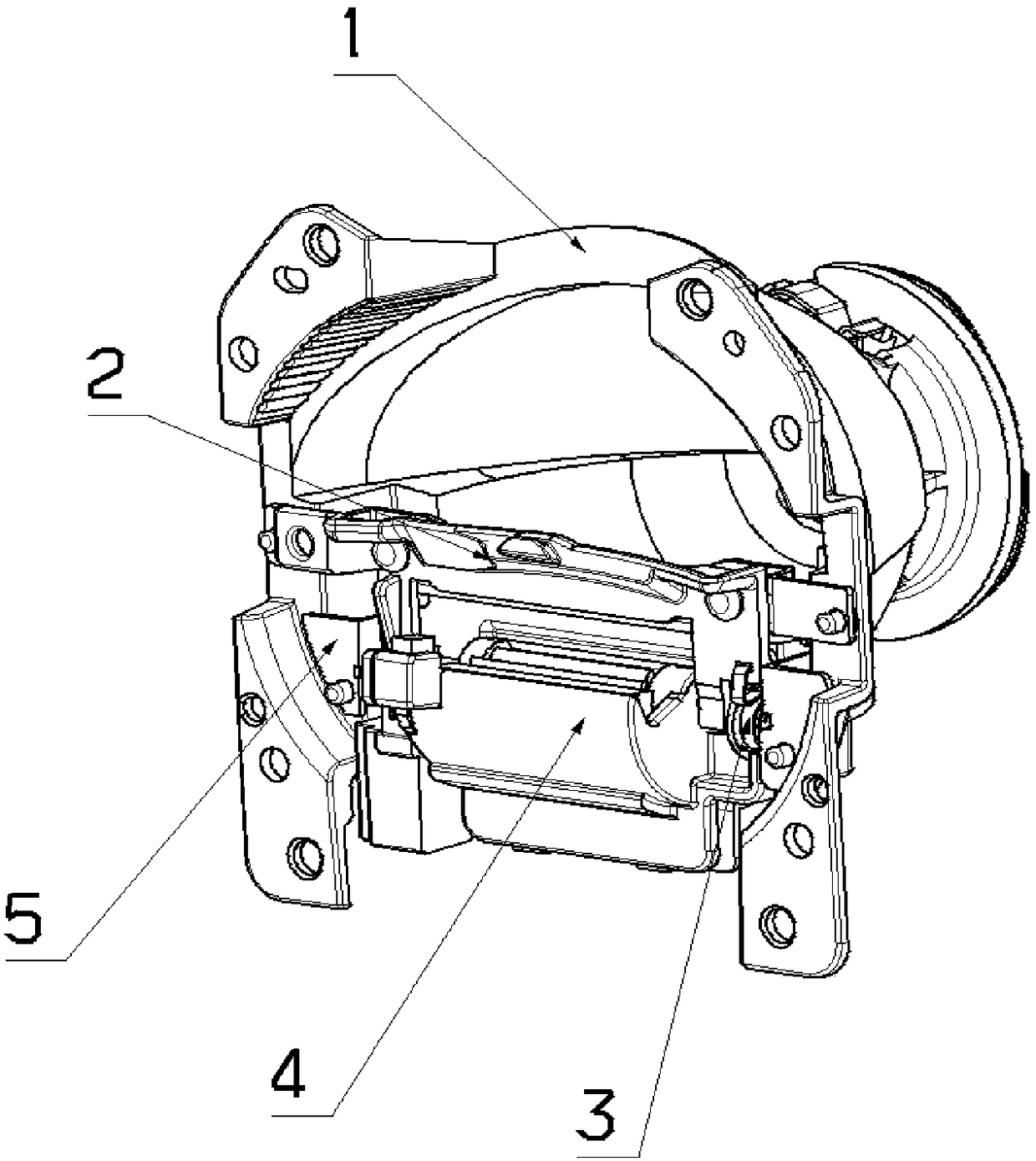

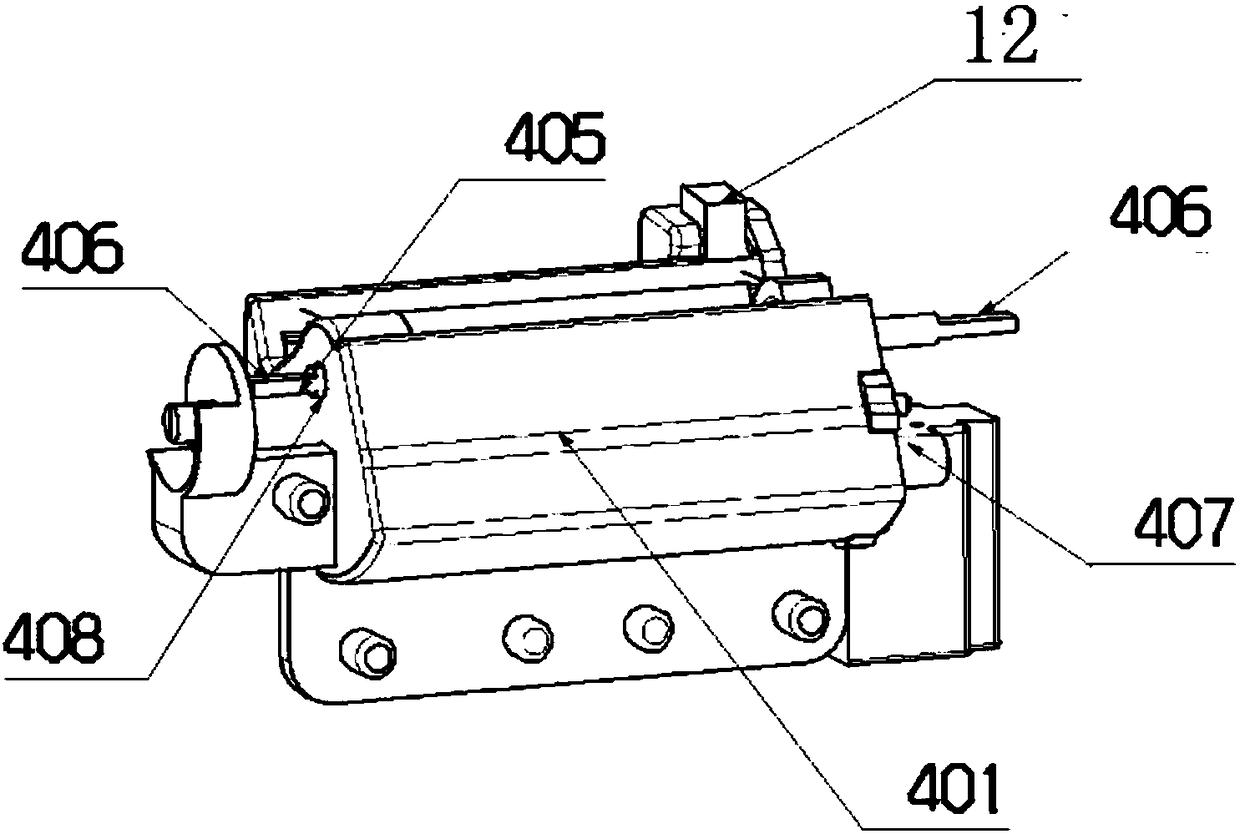

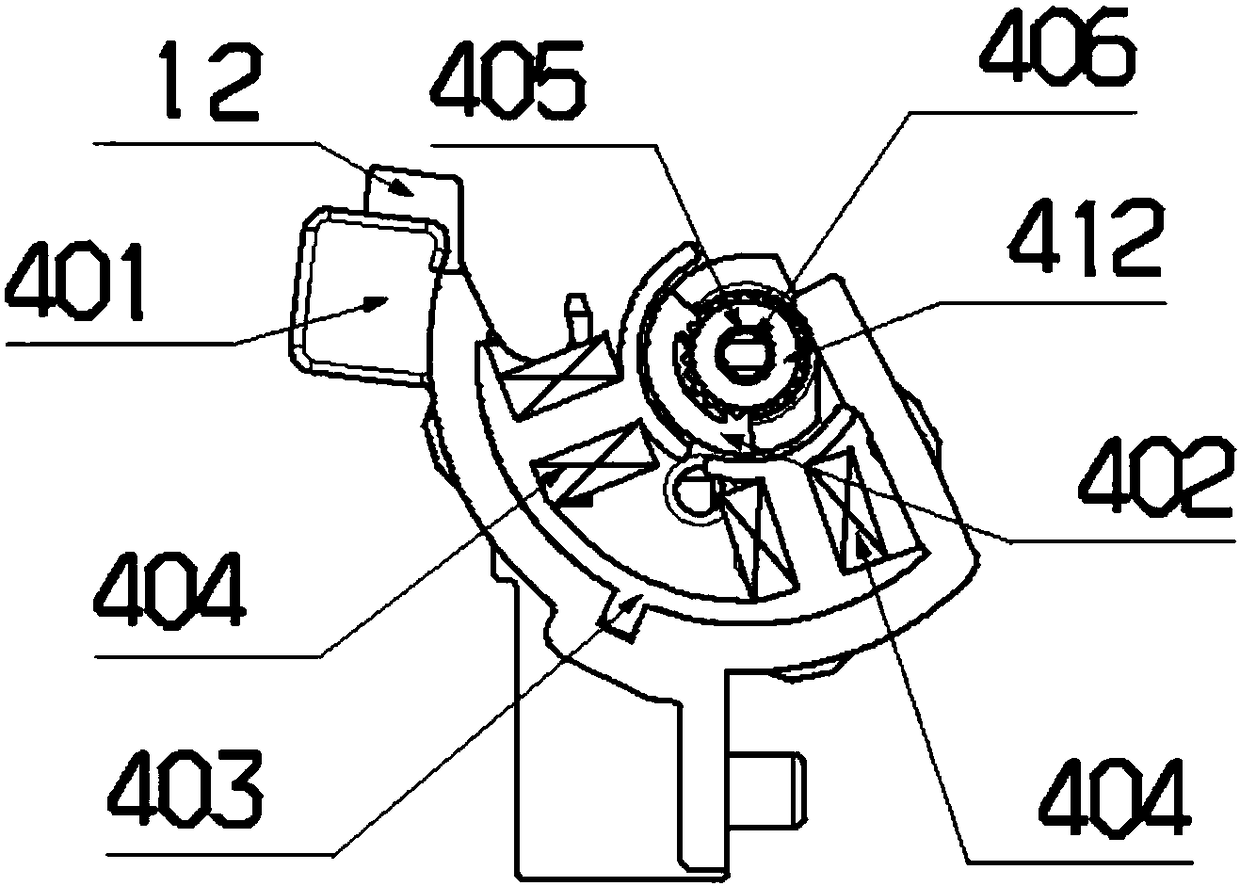

[0078] An embodiment of the optical type conversion driving device is shown in the figure. In the embodiment of the optical type conversion driving device shown in the accompanying drawings, it includes a housing 401, a rotating shaft subassembly 402, a stator core 403, a rotating shaft 405 and an end cover 407, used to drive the movable sunshield 2 of the vehicle light type conversion device. In order to more clearly show the internal structure of the optical type conversion driving device 4, image 3 with Figure 4 The end cap 407 is omitted.

[0079] The stator core 403 is provided with a stator winding 404 , and the stator core 403 and the stator winding 404 are fixedly installed inside the housing 401 to form a pair of arc-shaped stator poles that can be energized and excited.

[0080] The rotating shaft subassembly 402 is an arc-shaped magnetic steel part, which is fixed on the rotating shaft 405 and placed in the magnetic field space of the arc-shaped magnetic pole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com