A biomass-derived fuel gasification test device

A technology of derived fuel and test device, which is applied to the feeding tool of gasification device, granular/powder fuel gasification, gasification process, etc., can solve the problems of uneven feeding, poor operation continuity, complex structure, etc. Continuity and uniformity, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

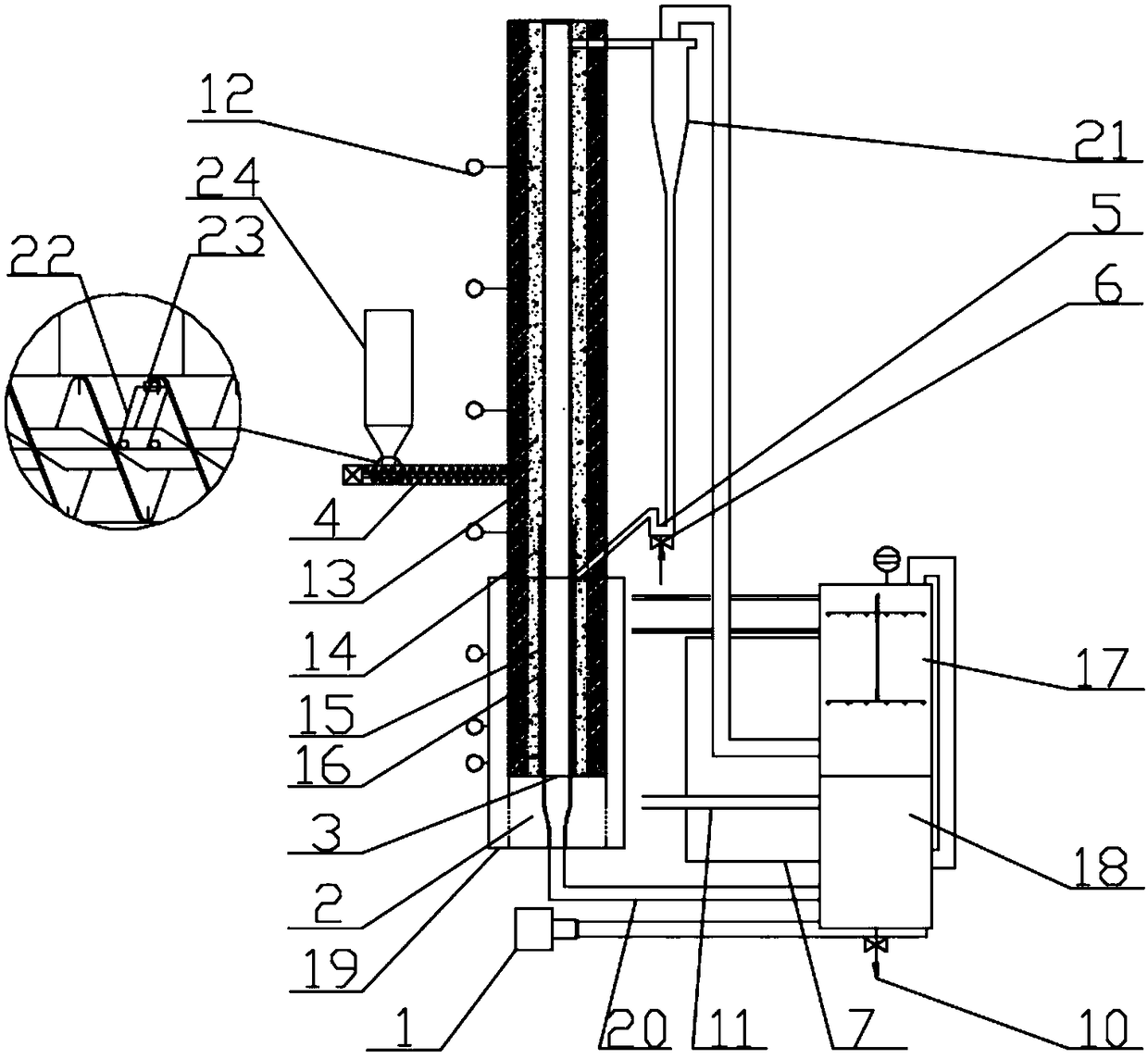

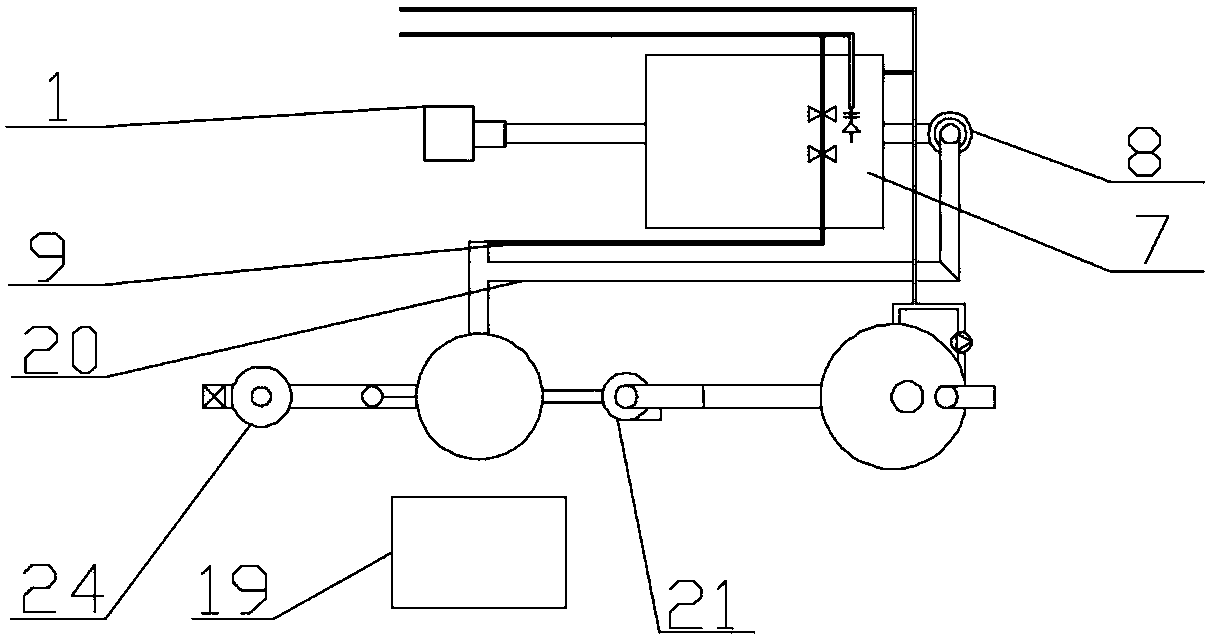

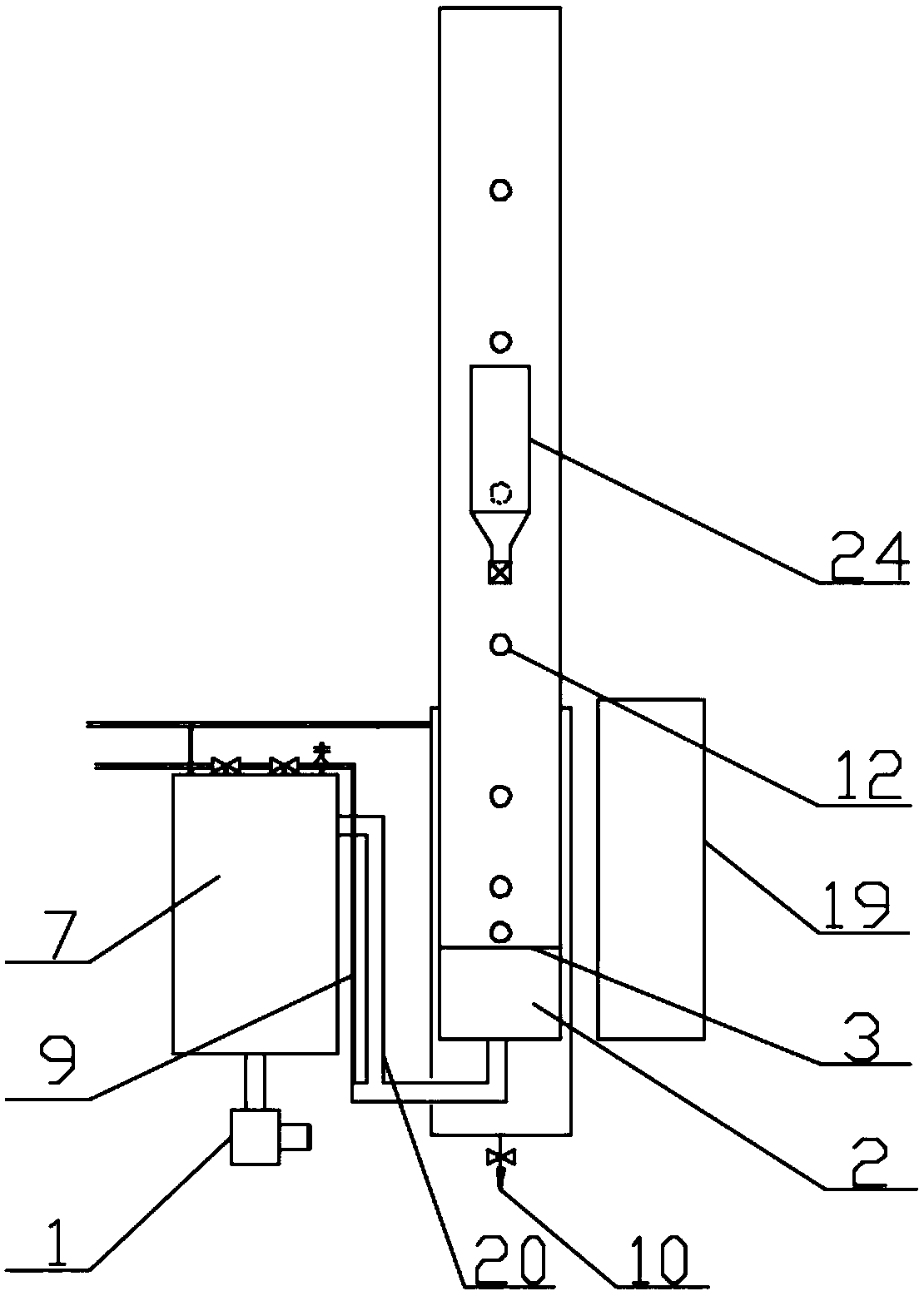

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] see Figure 1 ~ Figure 3 , a biomass-derived fuel gasification test device, comprising an electric control box 19 and a fluidized bed gasifier 15, the fluidized bed gasifier 15 is sequentially provided with a heating sleeve 16, a refractory concrete layer 14 and insulation layer 13, and a wind chamber 2 is provided at the bottom of the fluidized bed gasification furnace 15. In this embodiment, an air distribution plate 3 is arranged on the top of the air chamber 2, so that the air flow can evenly enter the fluidized bed gasification furnace. The concrete forming the refractory concrete layer 14 uses cement aluminum sulfate cement as the cementitious material.

[0019] The fluidized bed gasifier 15 is connected with a feeding mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com