Equipment for manufacturing thin-walled pipe inner liner, and method thereof

A technology for thin-walled pipes and inner linings, applied in coatings, metal material coating processes, etc., can solve problems such as burn-through, decarburization, and melting of the inner wall of pipe fittings, so as to improve yield, quality, and mechanical shock resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

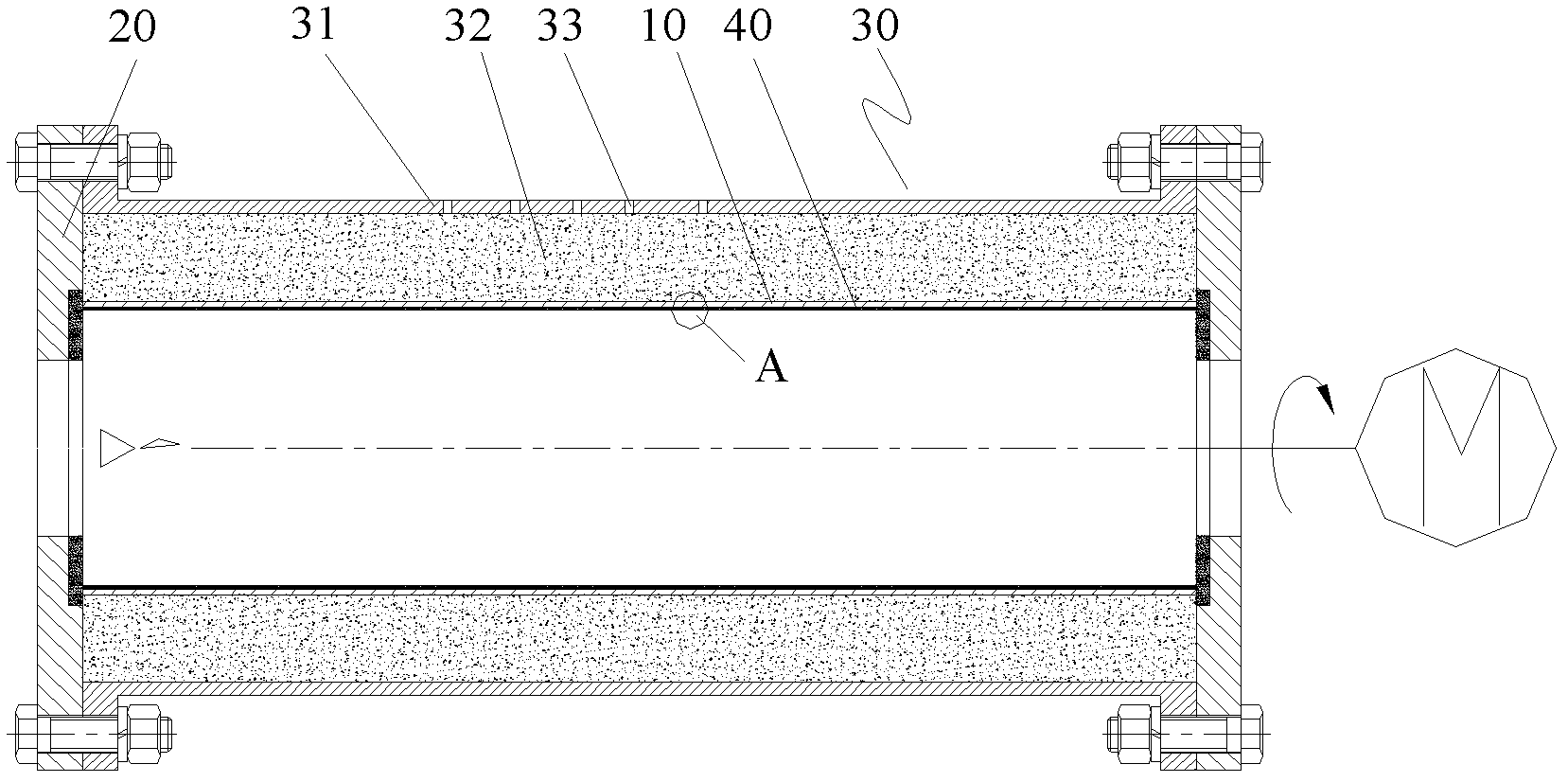

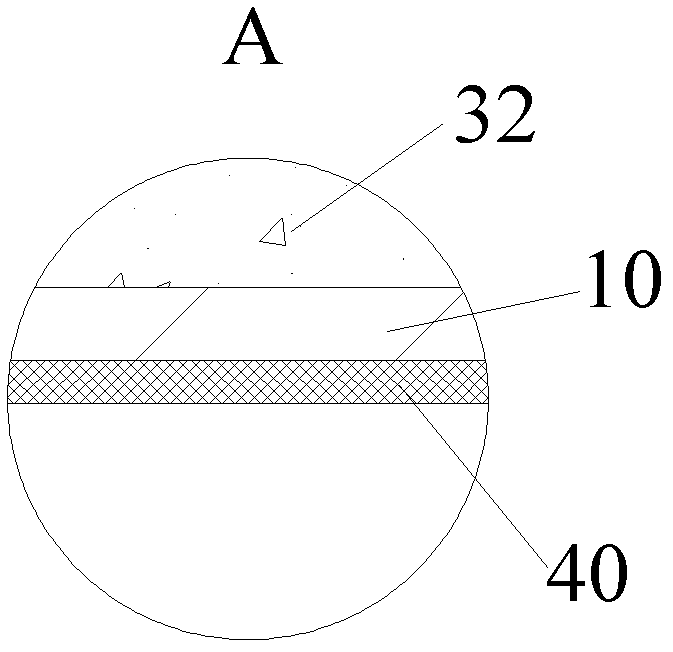

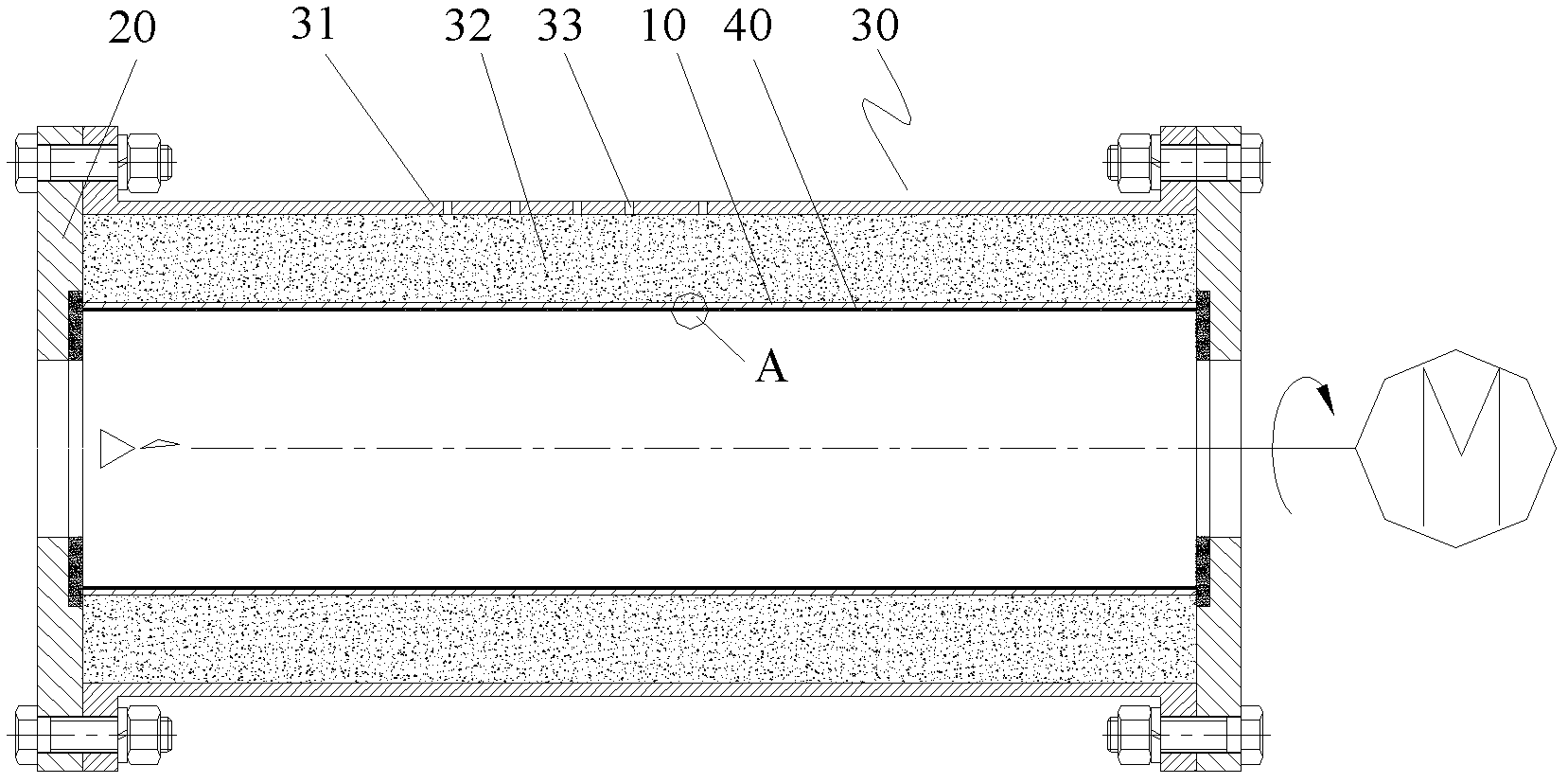

[0019] like figure 1 and figure 2 As shown, according to the embodiment of the present invention, the equipment for manufacturing the inner lining of the thin-walled pipe includes end caps 20 arranged at both ends of the thin-walled pipe 10, and also includes an outer barrier 30 wrapped around the outer layer of the thin-walled pipe 10. The blocking wall 30 is fixedly arranged between the end caps 20 at both ends. The outer retaining wall 30 is made of a material different from that of the thin-walled pipe 10 , and will not react with the thin-walled pipe 10 under high temperature conditions, nor will it be bonded to the thin-walled pipe 10 under the influence of high temperature.

[0020] The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com