Multi-head trenching machine

A trough forming machine, multi-head technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of low trough forming efficiency, complex structure, expensive equipment, etc., and achieve the effect of fast grooving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

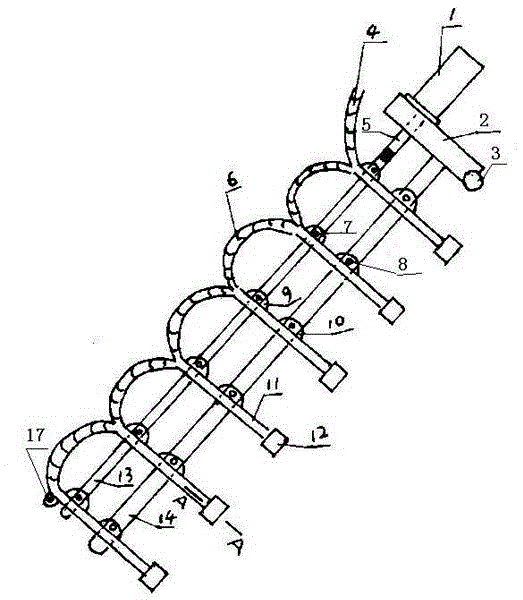

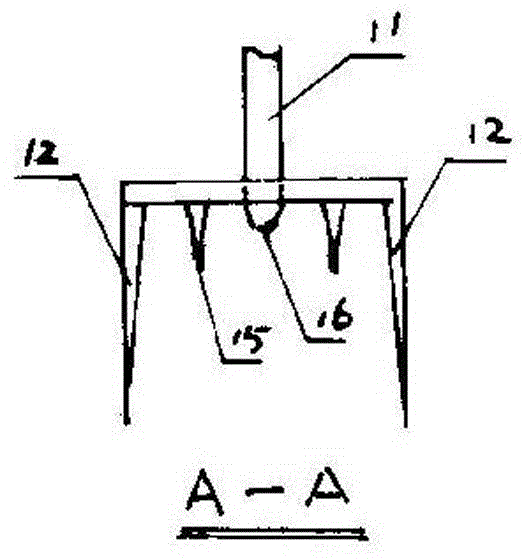

[0013] The accompanying drawing is a specific embodiment of the present invention, which includes a panel 2 on the upper part of the slotting machine, a support 3 at the lower end of the panel, a hydraulic cylinder 1 on the right side of the panel is fixed on the panel, and the output shaft 5 of the cylinder passes through the panel It is hinged with the upper end of the pull rod 13, the upper end of the main rod 14 is fixed with the panel, the knife bar 11 is provided with several according to the size of the groove depth, the upper part of each knife bar is provided with a hinge seat A9, the middle part is provided with a hinge seat B10, and the lower end is provided with a hinge seat A9. There is a water nozzle 16, the two sides of the water nozzle are respectively provided with a knife tooth 15, and the outermost sides of the two knife teeth are respectively provided with a side knife 12, the side knife is a rectangle with a certain width and a certain height, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com