Manufacture method for heat exchanger and manufacture method for air conditioner

A technology for heat exchangers and manufacturing methods, applied in heat exchange equipment, heating methods, air conditioning systems, etc., can solve the problems of high heat exchanger performance and high cost, and achieve the effects of low price, performance realization, and heat exchange efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

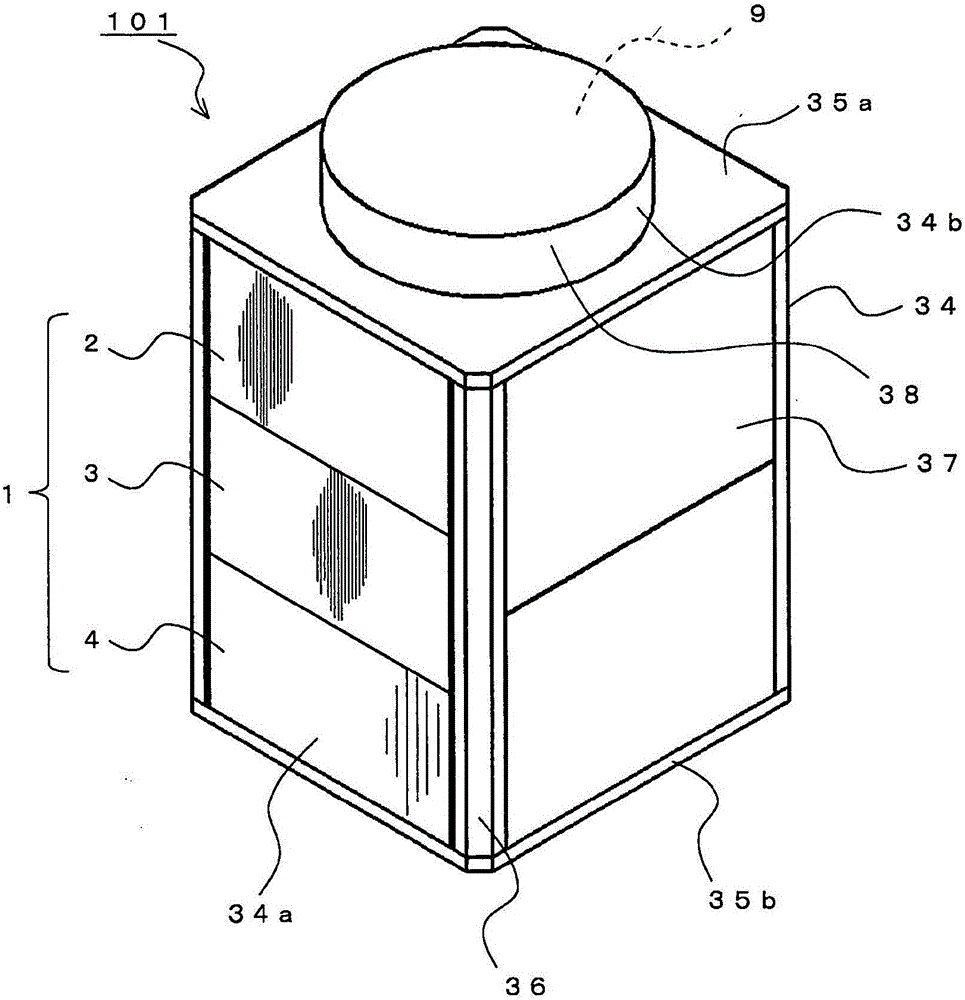

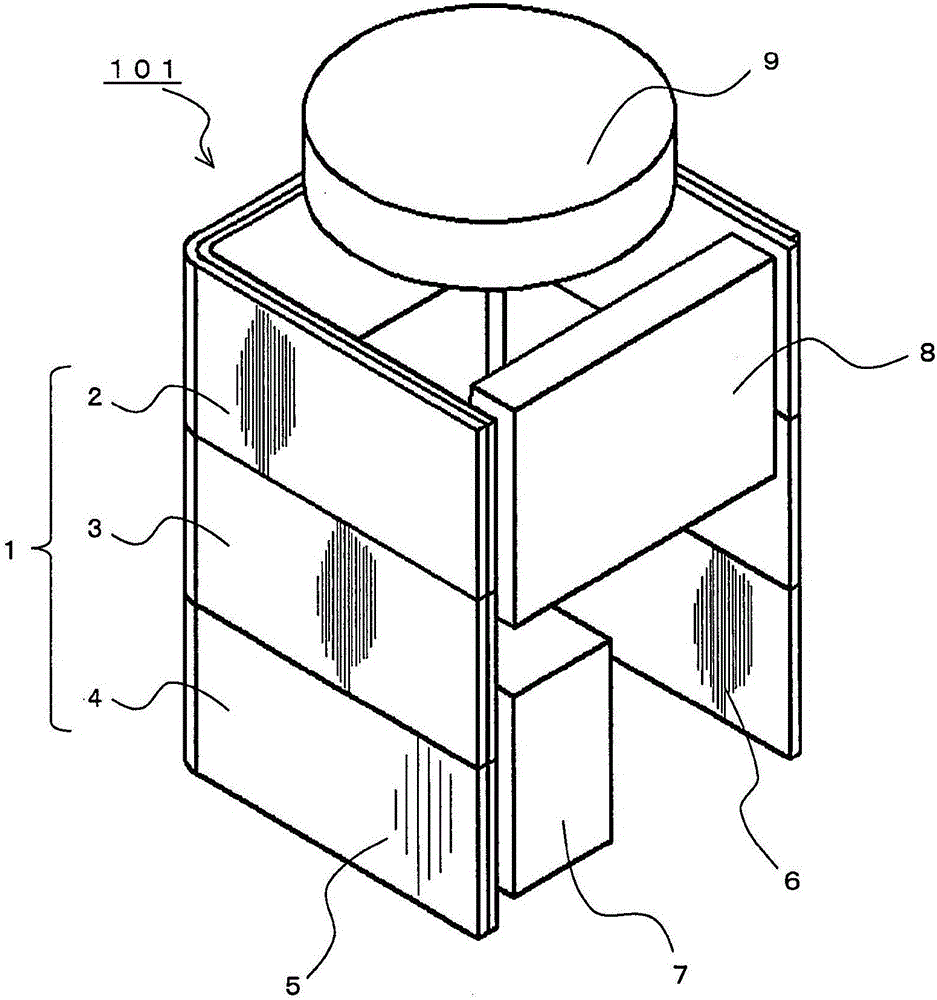

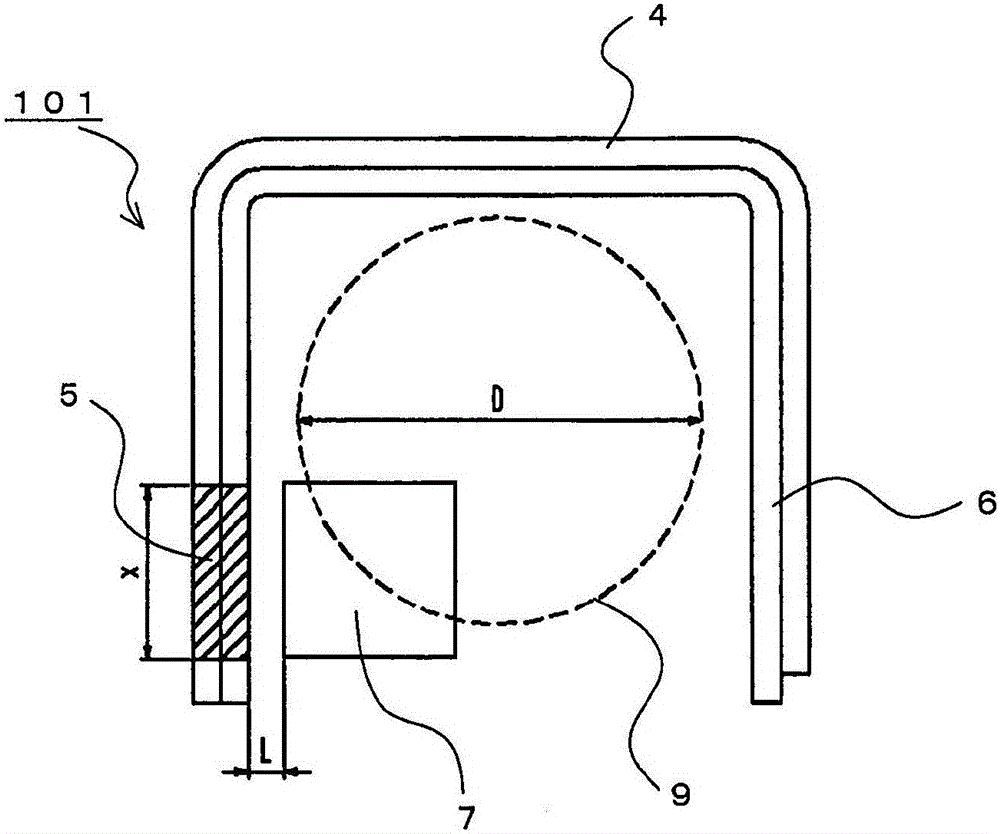

[0041] In the heat exchanger according to Embodiment 1, fin pitches in some ranges are formed to be larger than fin pitches in other ranges by an assembling method different from conventional ones in which fin pitches can be easily changed. In addition, the air conditioner according to the first embodiment includes the heat exchanger according to the first embodiment in which the fin density is optimally arranged in consideration of the internal structure of the case, and can achieve energy saving and low cost while maintaining performance equivalent to conventional ones. Cost, low price.

[0042] Hereinafter, the heat exchanger according to Embodiment 1, the method of manufacturing the heat exchanger according to Embodiment 1, and the air conditioner according to Embodiment 1 will be described in detail. In addition, below, the air conditioner of this Embodiment 1 is demonstrated taking the outdoor unit which mounted the heat exchanger of this Embodiment 1 as an example.

[...

Embodiment approach 2

[0082] In Embodiment 1, as an example of changing the fin pitch in a part of the range of the heat exchanger 1 , an example of changing the fin pitch in the compressor housing adjacent range 5 close to the compressor housing 7 was described. However, the range of changing the fin pitch is not limited to the compressor housing adjacent range 5 . It is also possible to vary the fin spacing of the heat exchanger 1 in the following ranges together with the compressor housing adjacent range 5 or separately from the compressor housing adjacent range 5 . In addition, in this Embodiment 2, about the structure which is not described especially, it is the same as Embodiment 1, and the same code|symbol is used for the same function and structure.

[0083] Figure 7 It is a top sectional view showing the heat exchanger and the control panel 8 in the outdoor unit according to Embodiment 2 of the present invention from the propeller fan side.

[0084] As in the first embodiment, the outdo...

Embodiment approach 3

[0093] The example of changing the fin pitch in a part of the range of the heat exchanger 1 is not limited to that shown in Embodiment 1 and Embodiment 2, and may be combined with or different from the structure of at least one of Embodiment 1 and Embodiment 2. From the structure of Embodiment 1 and Embodiment 2, the fin pitch of the heat exchanger 1 is changed in the following range. In addition, in Embodiment 3, the configurations not particularly described are the same as in Embodiment 1 or Embodiment 2, and the same functions and configurations are described using the same reference numerals.

[0094] Figure 9 It is a top cross-sectional view showing the heat exchanger in the outdoor unit according to Embodiment 3 of the present invention from the side of the propeller fan. Should Figure 9 The shown blank arrows indicate the flow of air inside the outdoor unit 101 .

[0095] The heat exchanger 1 according to Embodiment 3 is divided into two rows of heat exchanger sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com