Steel channel based manual leveling device of power distribution cabinet

A technology for leveling devices and power distribution cabinets, applied to substation/switch layout details, electrical components, etc., can solve problems such as laborious, time-consuming, and many times of adjustment, and achieve the goal of saving manpower and material resources, simple structure, and simplified leveling process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

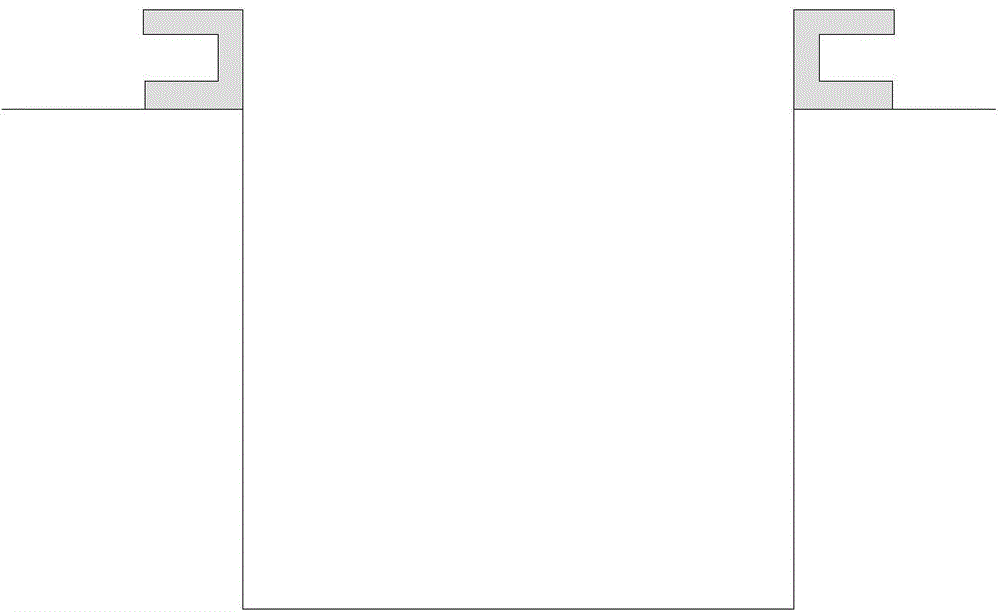

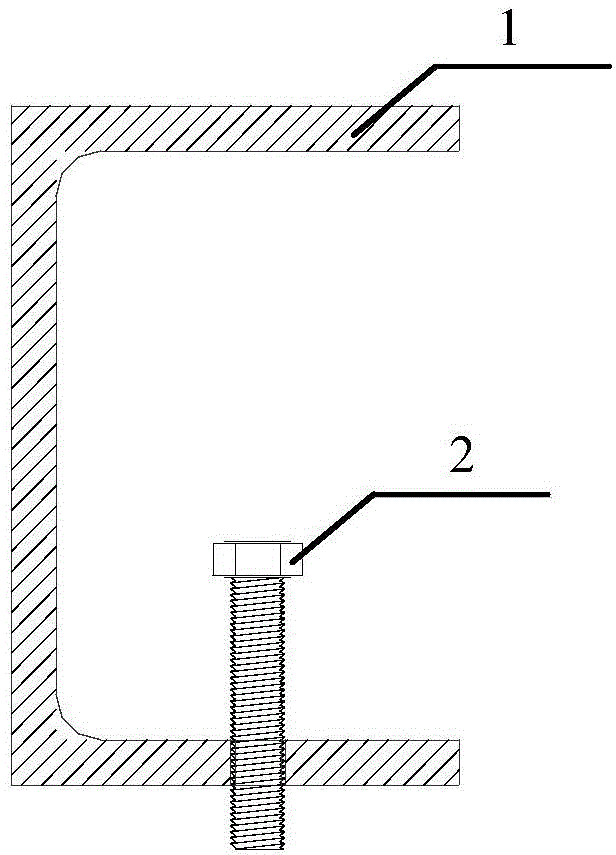

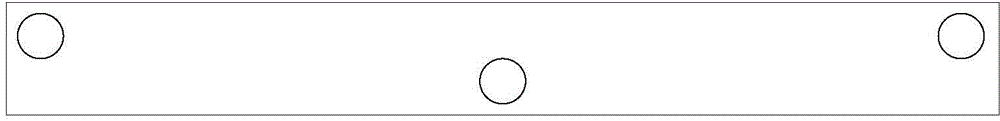

[0014] The invention provides a manual leveling device for a power distribution cabinet, and the leveling device includes two channel steels 1 . First, dig a deep pit on the ground for wiring as a wiring trough; set two channel steels on both sides of the opening of the wiring trough, and both channel steels are on the ground sideways. Three adjustment bolts 2 are installed on the side of each channel steel that is in contact with the ground. The three adjustment bolts are distributed at both ends and the middle of the channel steel, and the connection line of the three adjustment bolts forms an isosceles triangle, thus forming a stable support. noodle.

[0015] When it needs to be leveled, the left and right leveling can be realized by adjusting the adjusting bolts at both ends, and the front and rear tilting can be realized by adjusting the adjusting bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com