Resin encapsulation method and resin encapsulation device

A resin encapsulation device and resin encapsulation technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the unpredictable resin encapsulation, complex structure of resin encapsulation mold, manufacturing cost of resin encapsulation mold and resin encapsulation device Expensive and other problems, to achieve the effect of simplifying and omitting the mold structure, preventing poor molding, and reducing the overall manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

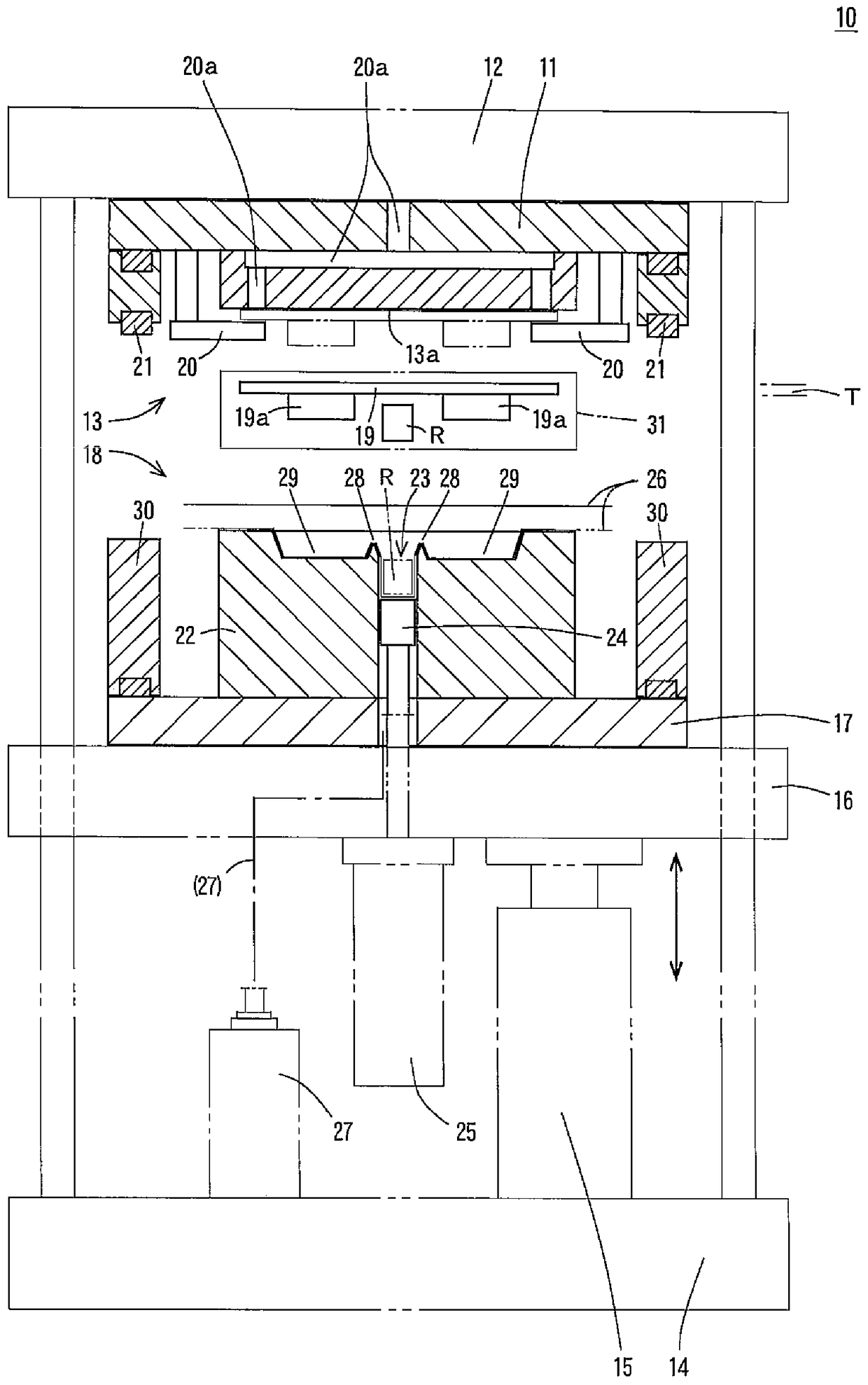

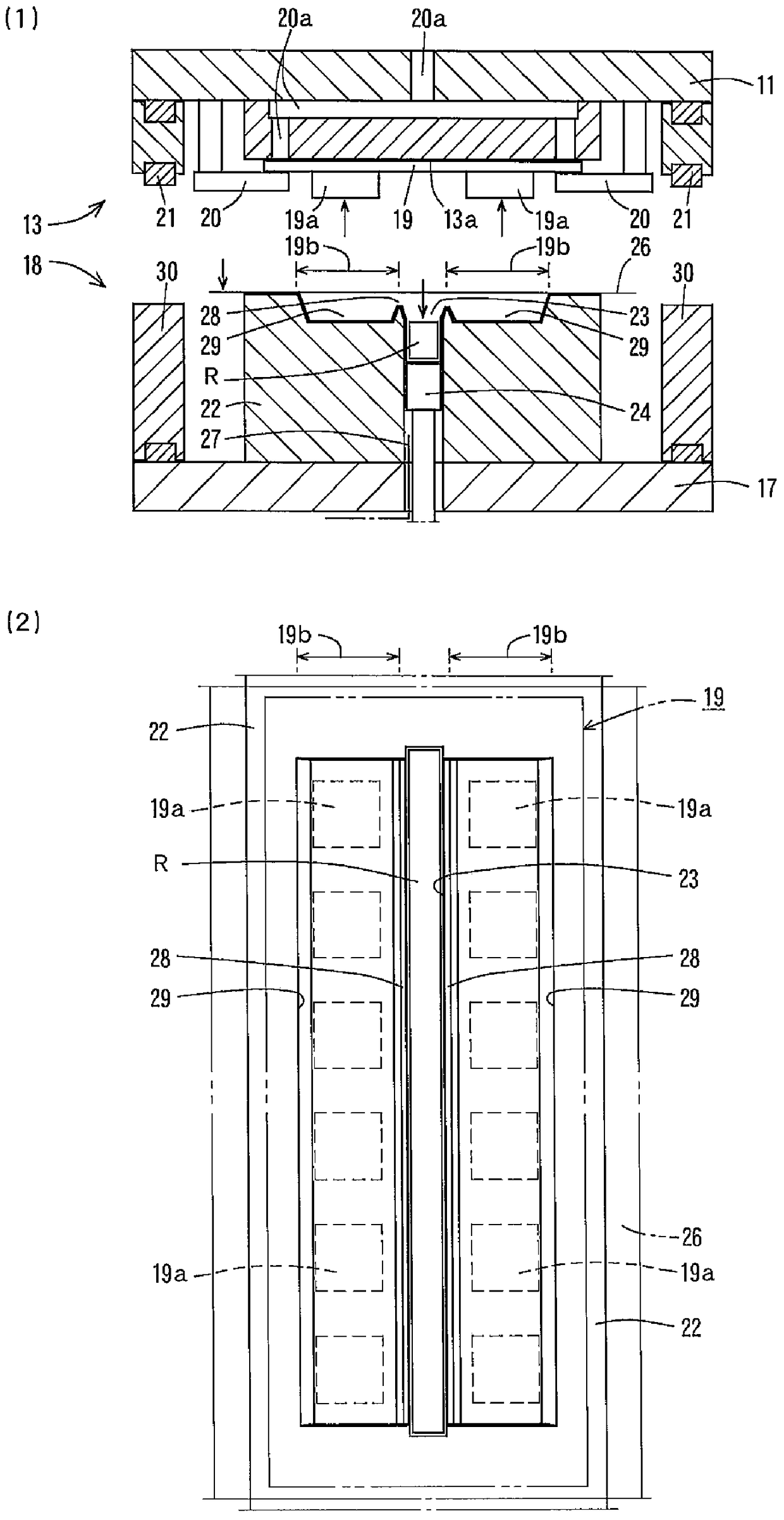

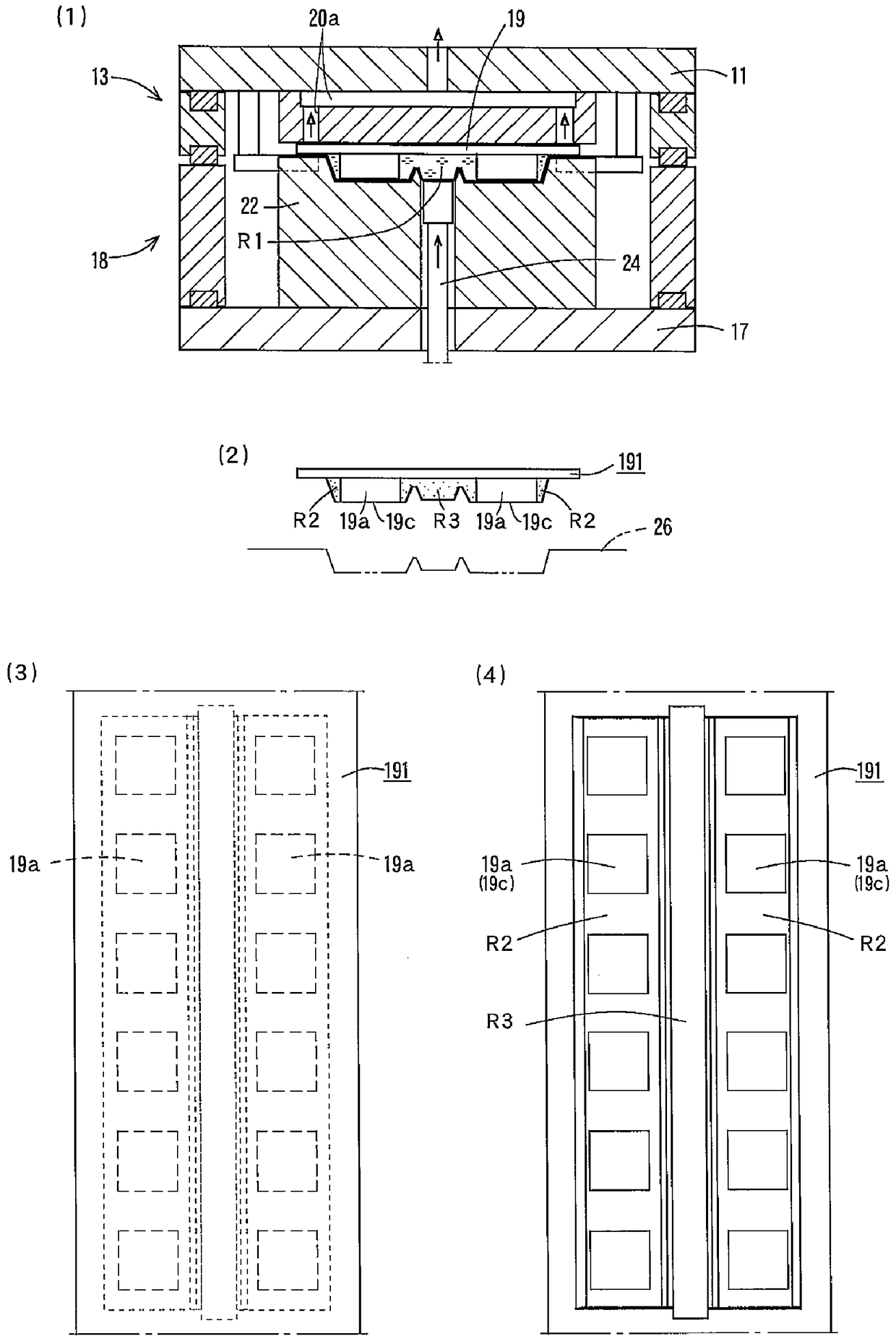

[0063] Below, according to Figure 1 to Figure 4 The illustrated embodiment diagrams illustrate the invention.

[0064] First, according to figure 1 , the outline of the resin sealing device 10 according to the present invention will be described.

[0065] This resin encapsulation device 10 has: upper mold 13, is fixed on the lower surface of fixed plate 12 via upper mold base 11; The movable plate 16 is provided so as to be movable up and down by a vertical drive mechanism 15 disposed on the base 14 of the resin encapsulating device 10 .

[0066] In addition, the parting surface (lower surface) of the upper mold 13 and the parting surface (upper surface) of the lower mold 18 are vertically opposed to each other, and the upper mold 13 and the lower mold 18 constitute a resin sealing mold.

[0067] In addition, the up and down driving mechanism 15 is configured so that the mold opening between the parting surfaces of the upper mold 13 and the lower mold 18 can be performed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com