Combined Piezoelectric Fuel Injection-Electromagnetic Jet Mixed Fuel Injection Device

A fuel injection device and injection device technology, applied in the direction of fuel injection device, oil supply device, charging system, etc., can solve the problems of engine knocking, unfavorable combustion, increase the complexity of device processing and assembly, etc., to ensure reliable performance and stability, and the effect of preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

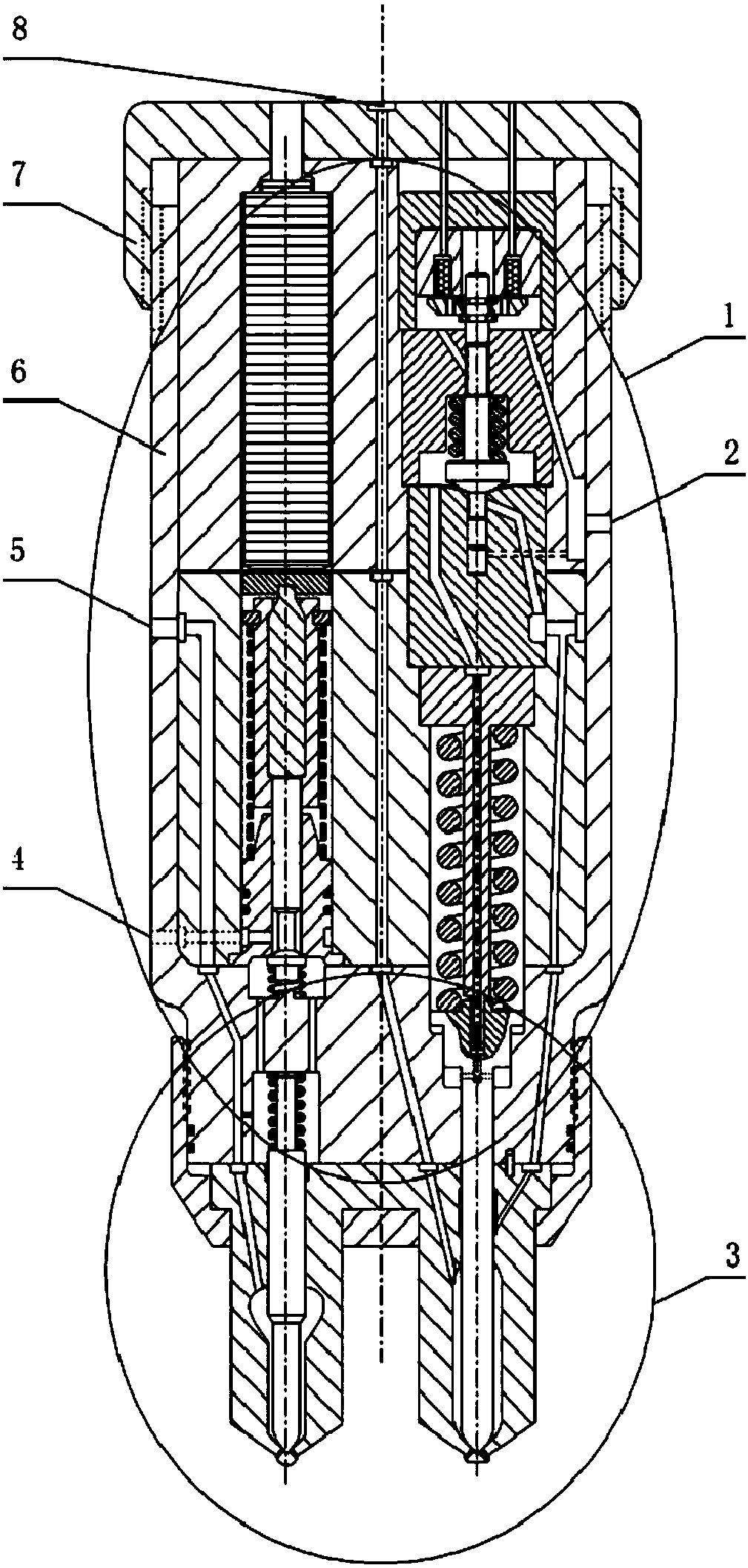

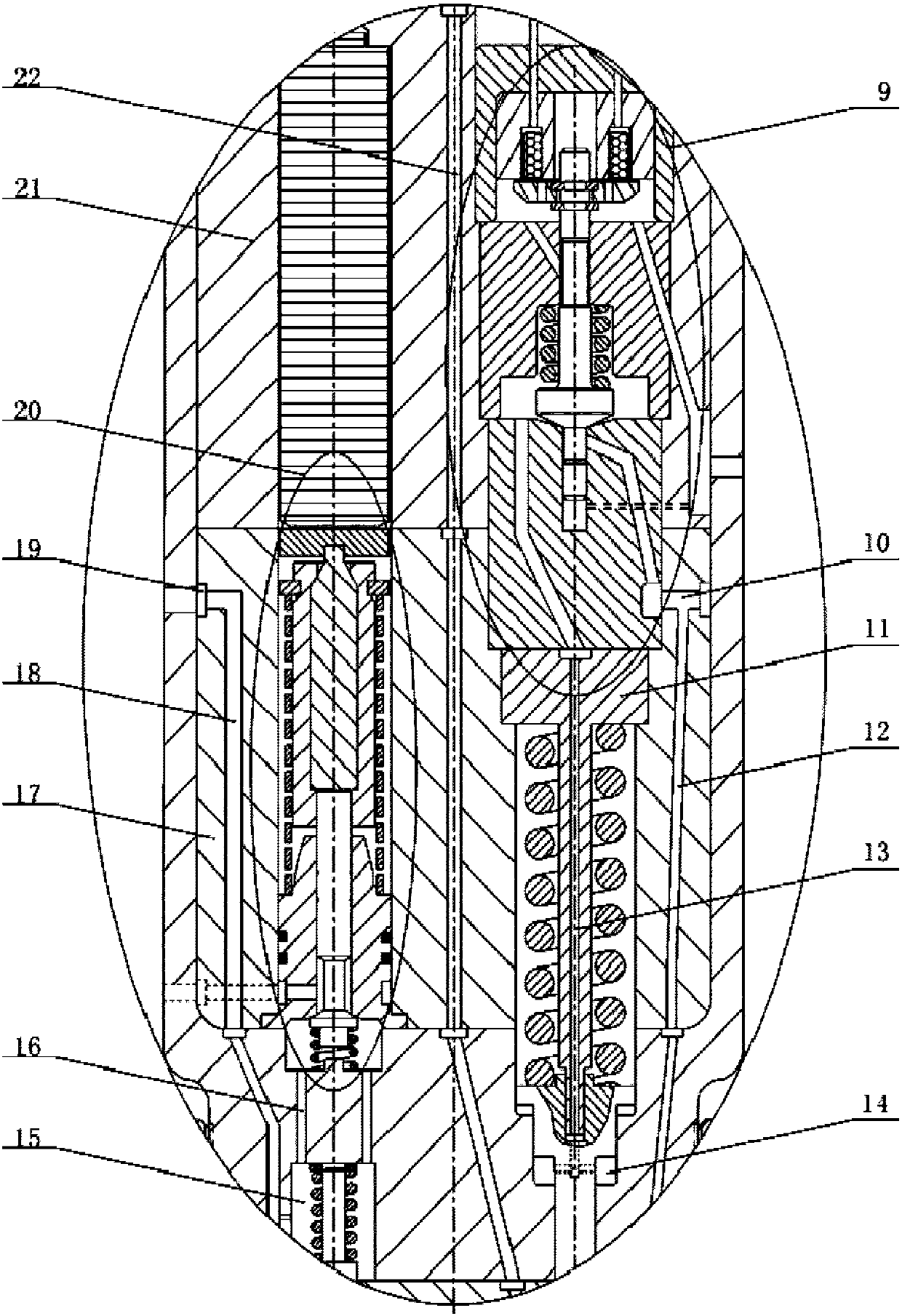

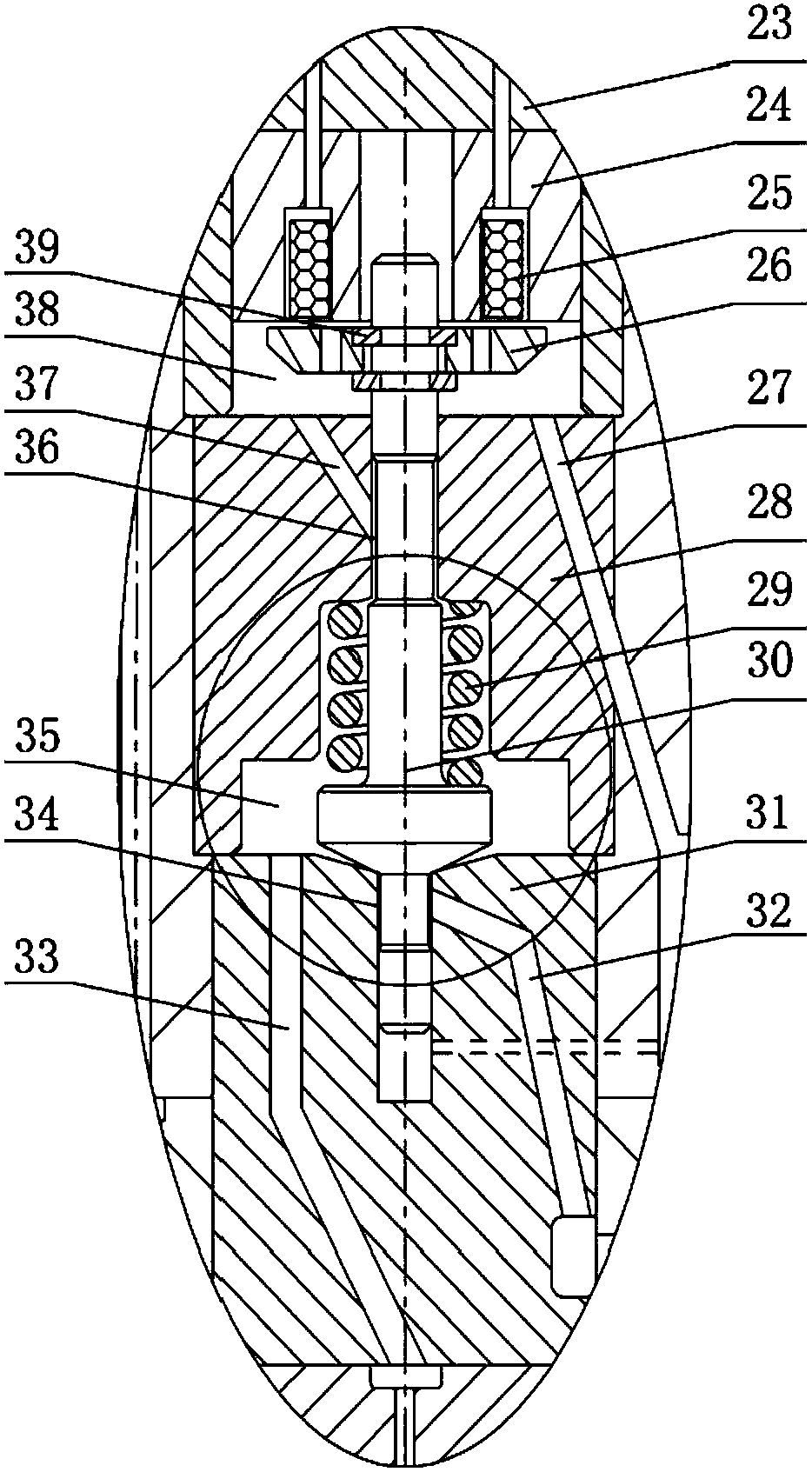

[0018] combine figure 1 ~3. The combined piezoelectric fuel injection-electromagnetic jet mixed fuel injection device of the present invention is mainly composed of piezoelectric-electromagnetic control part 1, double needle valve nozzle part 3, injection device body 6 and injection device upper cover 7. Piezoelectric-electromagnetic control part 1 mainly includes control gas solenoid valve 9, gas needle valve limit rod 11, gas needle valve control chamber 14, fuel needle valve control chamber 15, injection device inner cylinder 17, and fuel oil piezoelectric control valve 20 , Control valve sleeve 21 and so on. An annular oil groove 19 , an oil passage 18 , an oil passage 10 and a central air passage 22 are designed on the injection device inner cylinder 17 . The high-pressure control oil flowing in from the high-pressure fuel inlet 5 flows through the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com