Brick laying machine for building exterior wall

A technology for wall tiles and laying machines, applied in construction, building structure and other directions, can solve the problems of high labor intensity, difficult to form automatic laying effect, low work efficiency, etc., to reduce labor intensity, ensure the consistency of engineering quality, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

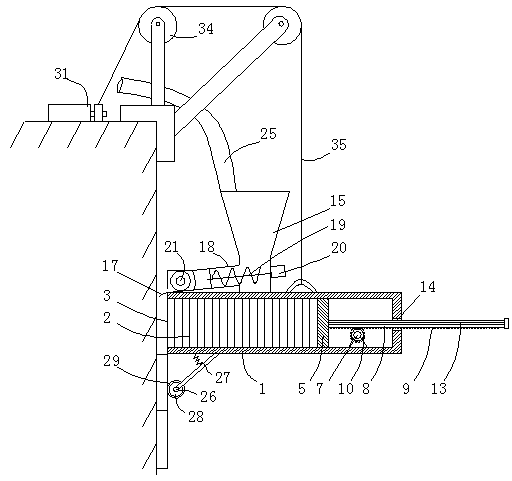

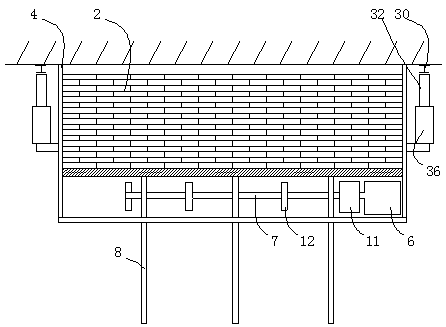

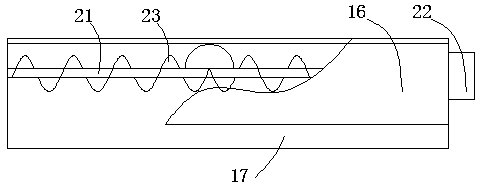

[0038] The optimal implementation mode: if figure 1 As shown in -5, a building exterior wall brick laying machine includes a wall brick storage box 1 for horizontal installation on the building exterior wall, and the inner cavity of the wall brick storage box 1 can accommodate the wall bricks 2 in the vertical state. Stacking, one end of the wall brick storage box is an open end and forms an outlet 3, and the other end is provided with a wall brick pushing device, which can be used to vertically arrange and stack the wall bricks 2 in the inner cavity of the wall brick storage box from the outlet 3 Pushing out, the upper side of the open end of the wall brick storage box 1 is provided with a plastering and grouting device for grouting and plastering the wall in front of the wall brick being pushed out, and also includes a supporting lifting device, which is used to lift the wall brick The outlet end of the accommodating box is directly supported on the wall and can realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com