Machining device with machining head capable of reciprocal motion

A reciprocating motion and processing device technology, applied in the direction of feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of push-pull drive accuracy, heavy processing head weight, complex workload, etc., to avoid size changes, run Reliable, guaranteed drive accuracy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

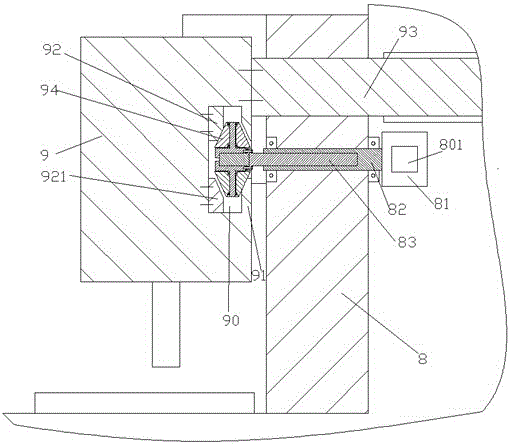

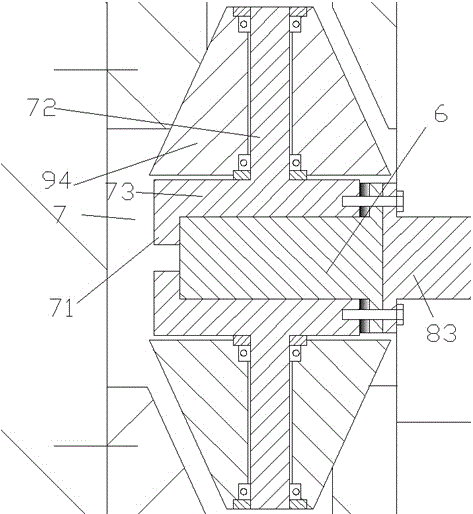

[0009] Combine below Figure 1-3 The present invention will be described in detail.

[0010] According to an embodiment of the present invention, a processing device with a reciprocating processing head includes a frame 8 and a processing head 9 reciprocally mounted on the frame 8 in the front-rear direction, wherein the processing head 9 A chute cavity 90 extending in the front-rear direction is provided, and the chute cavity 90 is used to roll and cooperate with the roller pusher so as to be pushed and pulled by the roller pusher to adjust the left-right direction perpendicular to the front-rear direction. position, wherein the roller pusher includes a threaded sleeve member 82 rotatably mounted on the frame 8 for threaded engagement with a threaded moving rod 83, and the threaded sleeve member 82 is driven to rotate by a drive motor 81, The thread moving rod 83 is detachably fixedly connected with a push head having two conical section roller assemblies arranged symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com