Flame-resisting yarn/fabric/clothes

A technology of flame retardancy and yarn, which is applied in the field of yarn/fabric/clothing, and can solve the problems of poor acid resistance, instability of aramid, and unsatisfactory length of fabric burning damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

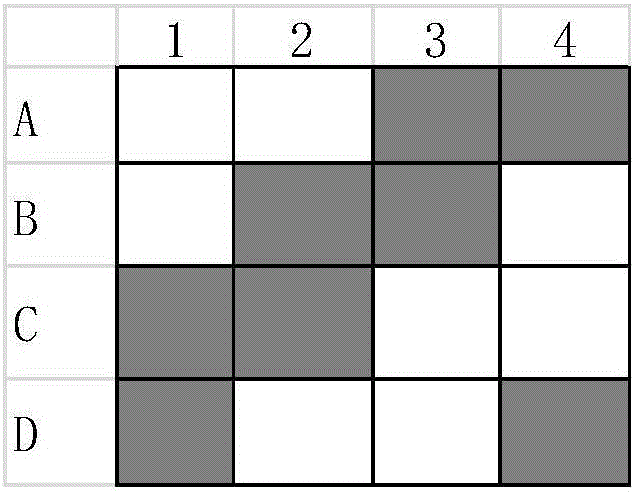

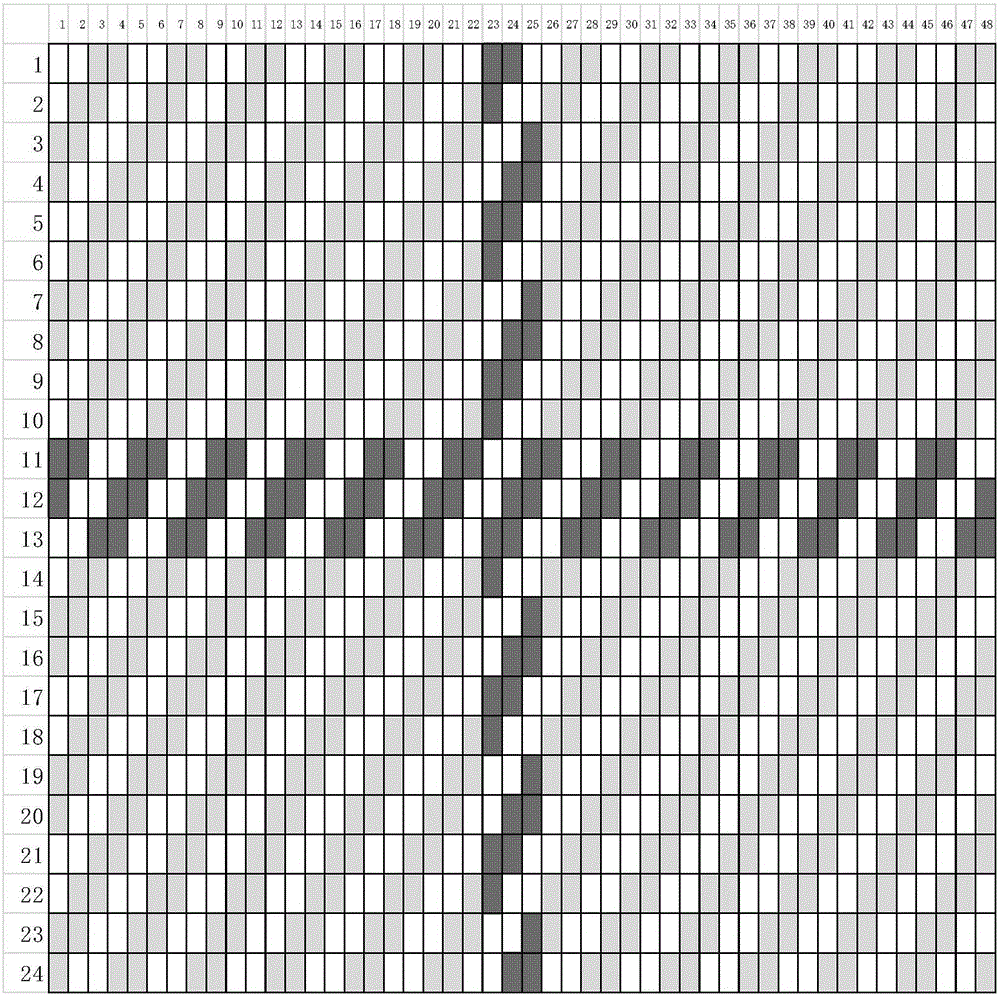

Image

Examples

Embodiment 1

[0071] A yarn providing flame resistance, consisting of the following mass percentages:

[0072] Denatured polyacrylonitrile: 75%;

[0073] Cellulose (cotton): 10%;

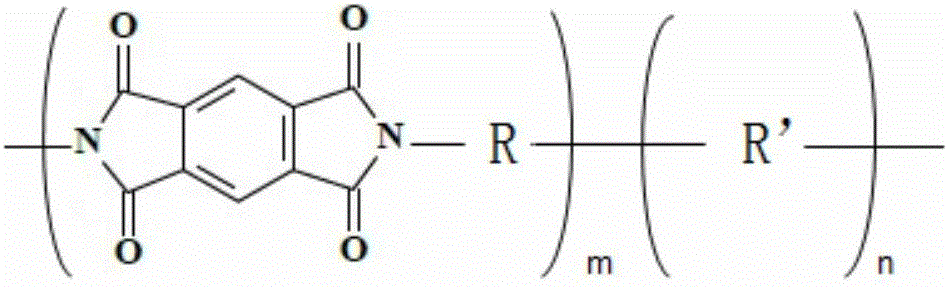

[0074] Polyimide: 13%;

[0075] Polyester-based carbon-containing anti-static fibers: 2%.

Embodiment 2

[0077] A yarn providing flame resistance, consisting of the following mass percentages:

[0078] Denatured polyacrylonitrile: 48%;

[0079] Cellulose (cotton): 49%;

[0080] Polyimide: 1%;

[0081] Polyester-based carbon-containing anti-static fibers: 2%.

Embodiment 3

[0083] A yarn providing flame resistance, consisting of the following mass percentages:

[0084] Denatured polyacrylonitrile: 45%;

[0085] Cellulose (cotton): 45%;

[0086] Polyimide: 8%;

[0087] Polyester-based carbon-containing anti-static fibers: 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com