Flame-retardant, high-temperature-resistant and corrosion-resistant multifunctional radiation-proof fabric

A multifunctional and fabric technology, applied in the field of textiles, can solve the problems of non-fouling, waterproof and chemical corrosion resistance, and achieve the effect of excellent acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

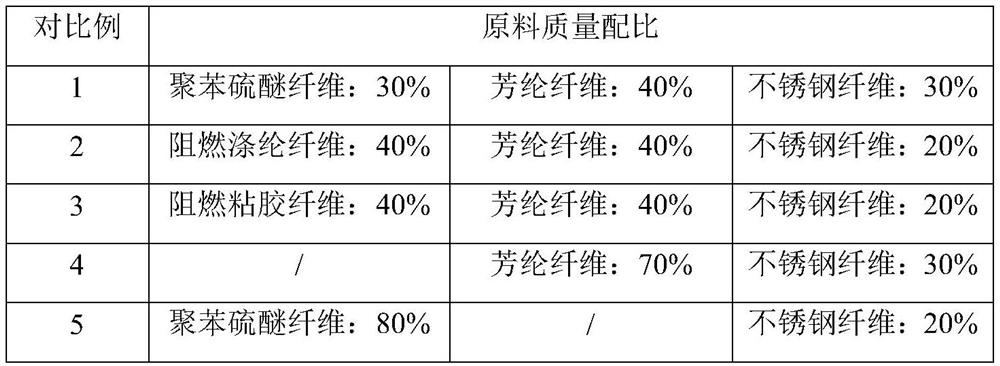

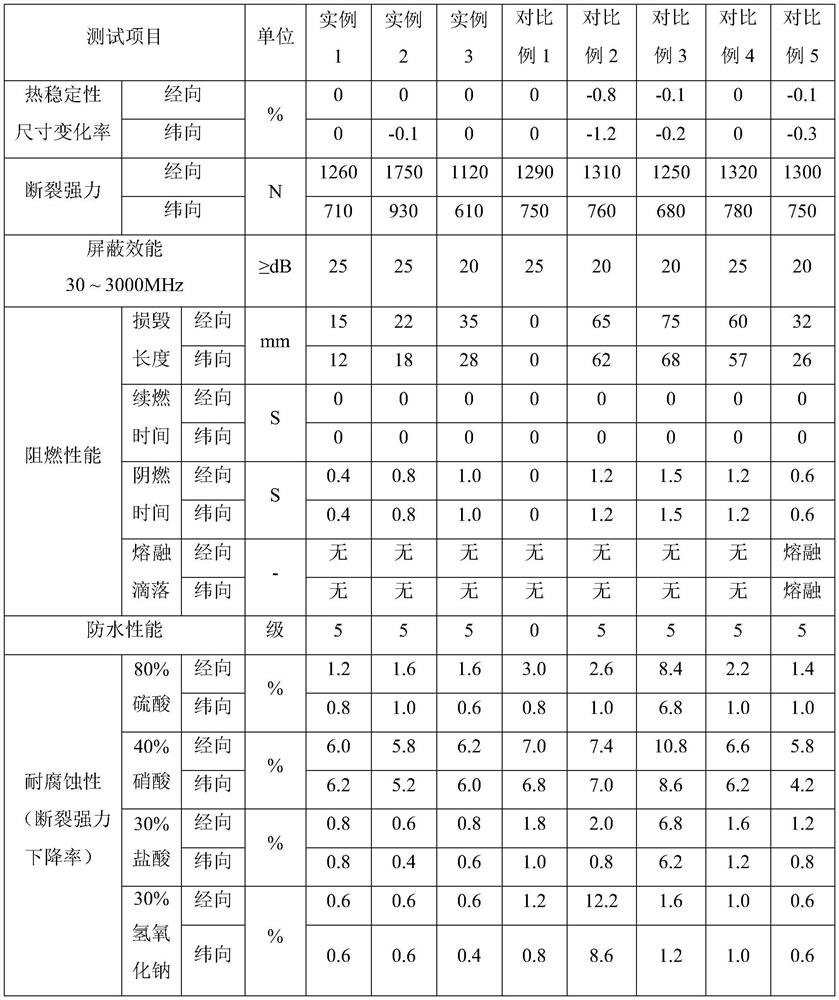

Examples

Embodiment 1

[0034] Polyphenylene sulfide fiber / aramid fiber / stainless steel fiber mixed yarn Polyphenylene sulfide fibers use 51 mm, 2.5dtex short fibers, and aramid fibers use natural araminal aramid 1313 / aramid 1414 mixed bars, its aramid 1313 / aramid 1414 mixed ratio of 90 / 10, stainless steel short fiber adopts 40 ~ 50mm, Fiber strip;

[0035] Method for preparing polyphenylene sulfide fiber / aramid fiber / stainless steel fiber mixed spinning, including the following steps:

[0036] The aramid fibers and polyphenylene sulfide fibers were cleaved, combined with a combination, and then mixed with a stainless steel fiber strip, and then produced as a polyphenylene sulfur. Ether fiber / aramid / stainless steel short fiber blending yarn, single yarn specification is 21 bibs;

[0037] Preparation of flame retardant, high temperature resistance, corrosion-resistant multi-function radiation protection fabrics, including the following steps:

[0038] Based on polyphenylene sulfide fiber ...

Embodiment 2

[0040] Adjustment Example 1 The mass ratio of polyphenylene sulfricated / aramid fiber / stainless steel short fibers is 40 / 40 / 20, and the yarn is changed to 32 bidding two-stranded line, and the weight of the fabric is adjusted to around 260 g / square meter. , Other conditions are the same as in Example 1 to obtain a fabric.

Embodiment 3

[0042] Adjustment Example 1 The mass ratio of polyphenylene sulfricate / aramid fiber / stainless steel short fibers is 25 / 50 / 25, and the yarn is changed to 30-British single yarn, and the tissue structure of the fabric is changed to 1 / 1 flat line. The weight of the fabric is adjusted to around 170 g / m2, and the other conditions are the same as in Example 1 to obtain a fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com