Preparation method for dialysis-resistant composite halogen-free flame-proof agent

A composite flame retardant and composite halogen-free technology, which is applied in the field of preparation of anti-dialysis composite halogen-free flame retardants, can solve the problems affecting the mechanical properties of materials, flame retardant processing performance and product surface properties, poor thermal stability, and application limitations and other problems, to achieve the effect of easy industrial production, good compatibility and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) The compound system formulated with the mass ratio of ammonium polyphosphate: pentaerythritol: melamine = 65:20:15 was dried in a vacuum oven at 80°C for 4 hours, and then 1 part of γ-aminopropyltriethoxysilane was added , stirred and mixed evenly at 100°C to obtain an active composite flame retardant;

[0017] Add a suspension system consisting of 1 part of glyoxal, 0.01 part of dicumyl peroxide, 0.08 part of antioxidant and 10 parts of ethanol to 100 parts of active composite flame retardant, stir and react at 150°C for 60 minutes, and cool and drying to obtain a dialysis-resistant composite halogen-free flame retardant with a particle size of 20-100 μm.

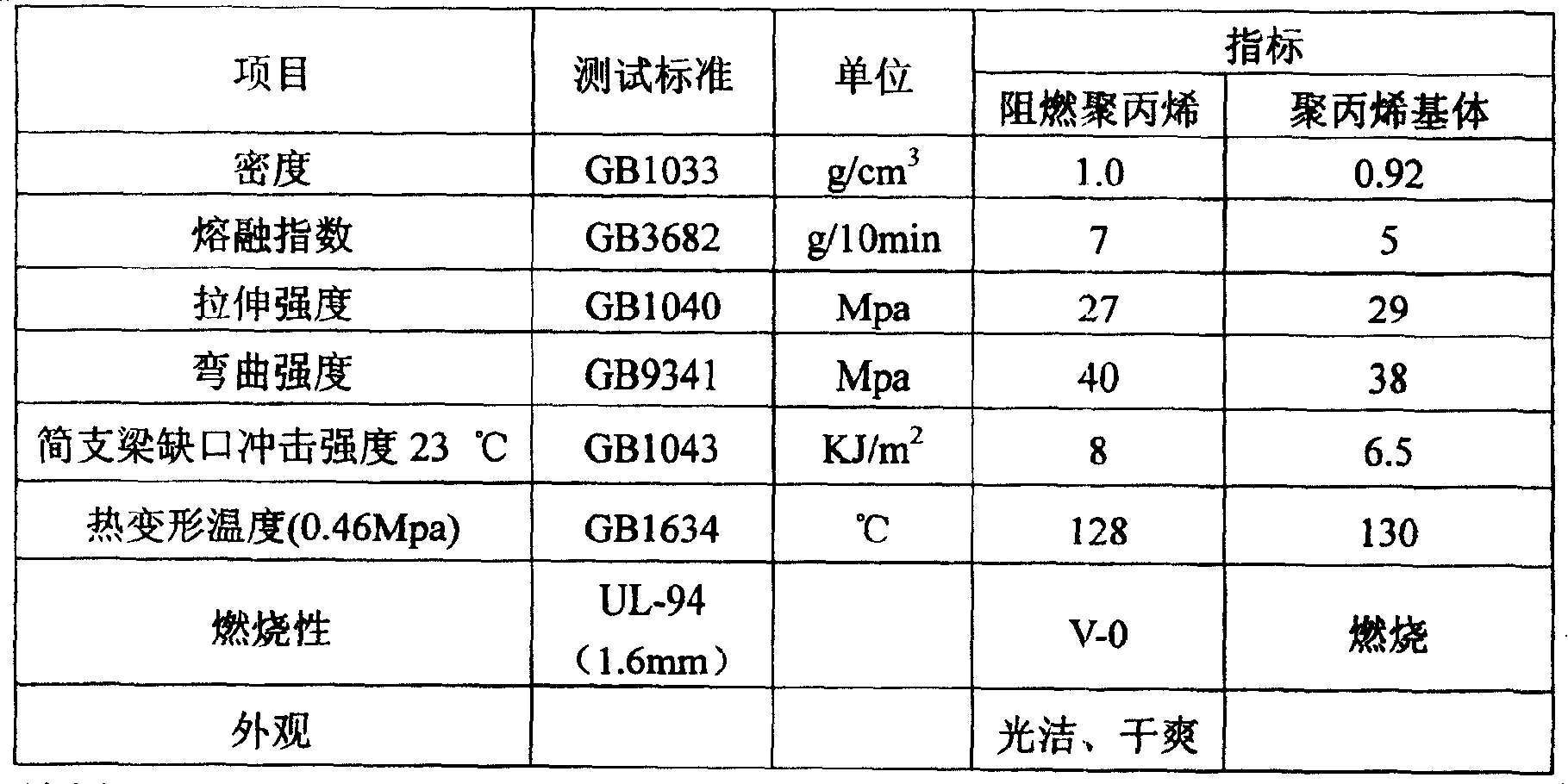

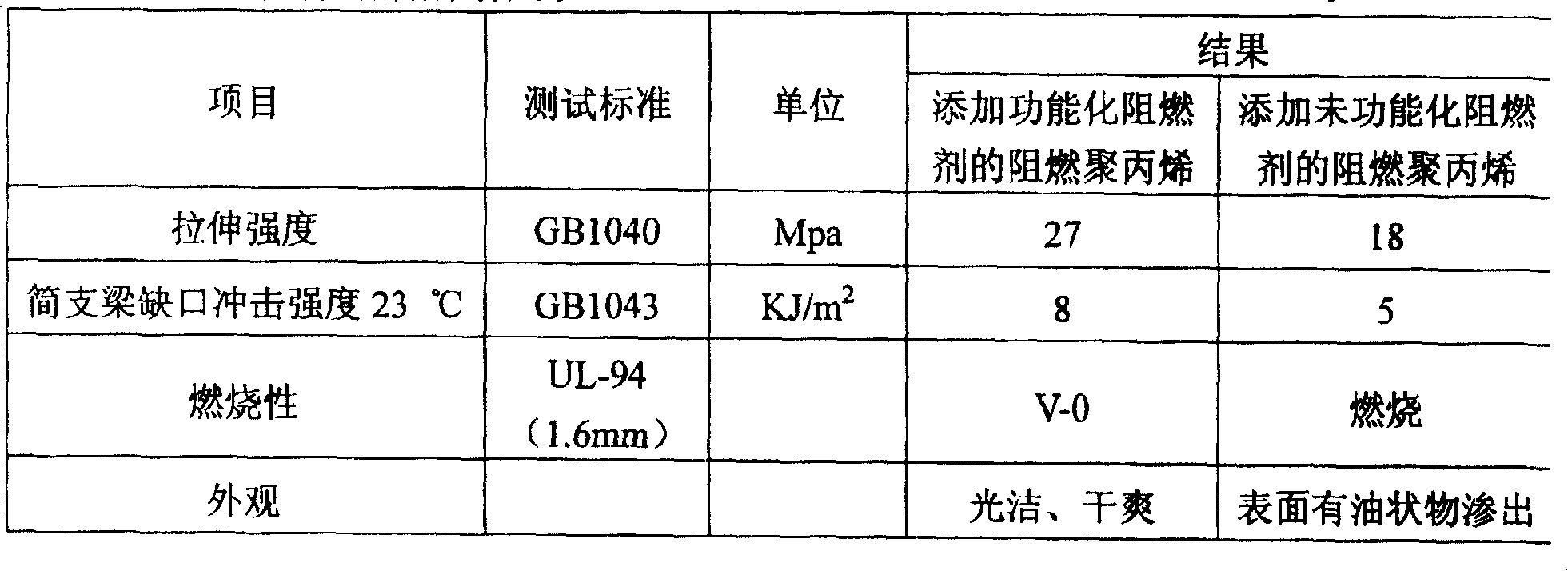

[0018] 2) Stir the above anti-dialysis composite halogen-free flame retardant and polypropylene at a mass ratio of flame retardant: polypropylene = 30:100 at high speed for 5 minutes, and then melt and extrude it through a twin-screw extruder at a barrel temperature of 150-180°C and injection molded to obtain te...

Embodiment 2

[0021] 1) The compound system formulated with the mass ratio of ammonium polyphosphate: pentaerythritol: melamine=40:35:25 was dried in a vacuum oven at 80°C for 4 hours, and then 0.5 parts of γ-glycidyloxypropyltrimethoxy base silane, stirred and mixed evenly at 150°C to obtain an active composite flame retardant;

[0022] Add a suspension system consisting of 3 parts of glutaraldehyde, 0.08 parts of dicumyl peroxide, 0.5 parts of antioxidant and 50 parts of ethanol to 100 parts of active composite flame retardant, stir and react at 150°C for 30 minutes, and cool and drying to obtain a dialysis-resistant composite halogen-free flame retardant with a particle size of 20-100 μm.

[0023] 2) Stir the above-mentioned anti-dialysis composite halogen-free flame retardant and polypropylene at a mass ratio of flame retardant: polypropylene = 30:100 at high speed for 5 minutes, and then melt through a twin-screw extruder at a barrel temperature of 150-180°C Extruded and injection mol...

Embodiment 3

[0026] 1) The mass ratio of ammonium polyphosphate: pentaerythritol: melamine = 80:15:5 formulated compound system, dried in a vacuum oven at 80°C for 4hr, then added 2 parts of isopropyl tri(isostearate Acyl) phthalate, stirred and mixed uniformly at 80°C to obtain an active composite flame retardant;

[0027] Add the suspension system consisting of 10 parts of glutaraldehyde, 0.1 part of benzoyl peroxide, 0.02 parts of antioxidant and 100 parts of ethanol to 100 parts of active composite flame retardant, stir and react at 220 °C for 30 minutes, after cooling, drying to obtain a dialysis-resistant composite halogen-free flame retardant with a particle size of 20-100 μm.

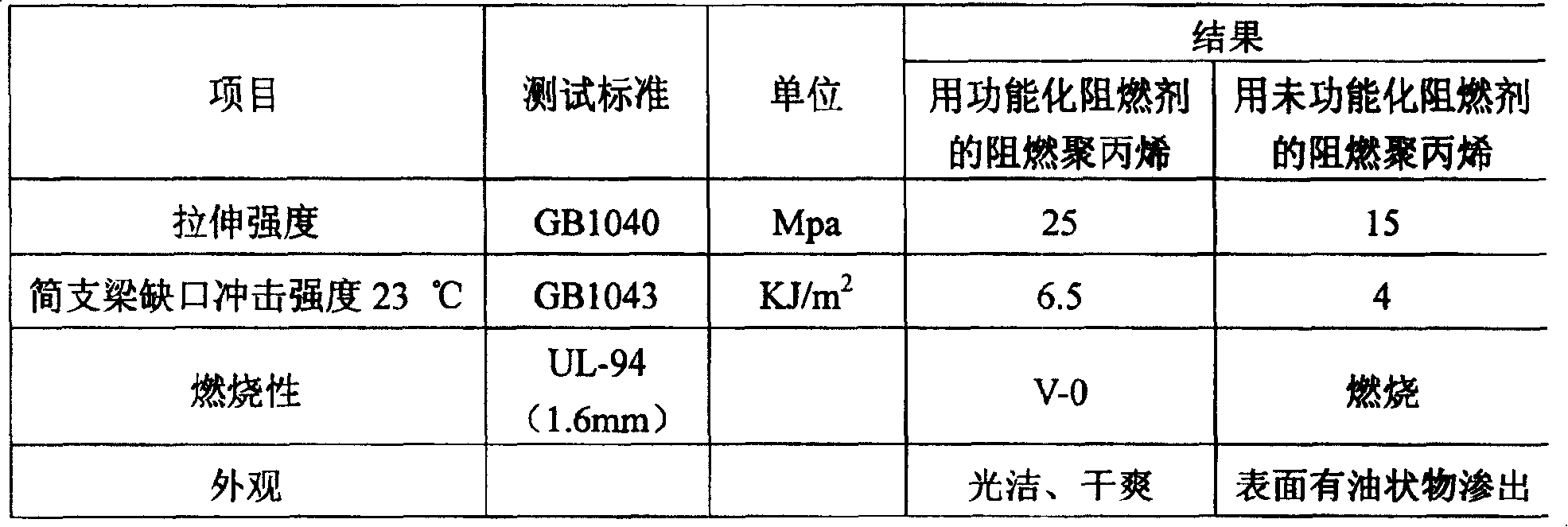

[0028] 2) Stir the above-mentioned anti-dialysis compound halogen-free flame retardant and polypropylene at a mass ratio of flame retardant: polypropylene: talcum powder = 30: 100: 30 at high speed for 5 minutes, and then pass through a twin-screw extruder at a barrel temperature of 150 Melt extrusion at ~2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com