A kind of flame retardant polyamide fiber and preparation method thereof

A flame-retardant polyamide, polyamide technology, applied in the manufacture of fire-resistant flame-retardant filaments, fiber treatment, conjugated synthetic polymer artificial filaments, etc., can solve poor spinnability, difficult industrial applications, mechanical properties and flame-retardant Performance can not be taken into account and other issues, to achieve the effect of low cost, less addition, no melt dripping flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of flame retardant polyamide fiber, the specific process is as follows:

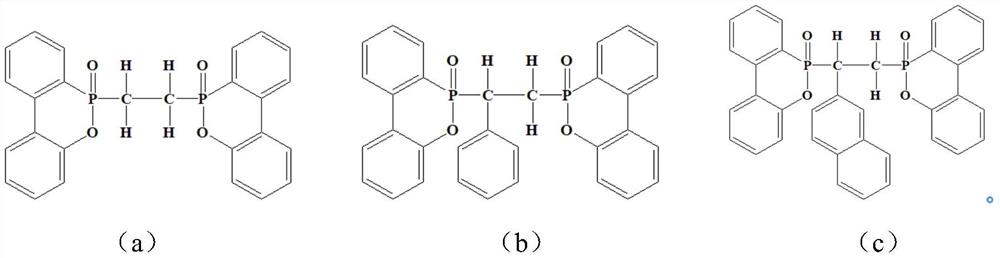

[0032] (1) 94 parts of nylon 6, 3.5 parts of melamine cyanurate, 0.5 parts of graphite-like carbon nitride, 0.5 parts of zinc sulfide and 1.5 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene -10-oxide derivatives are melt-blended to obtain flame-retardant polyamide chips, wherein the temperature of melt-blending is 270°C, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxidation The structural formula of the derivative is:

[0033]

[0034] (2) Dry and pre-crystallize the flame retardant polyamide chips. The process is as follows: first, the temperature is raised from 20°C to 65°C within 0.75h, and the temperature is kept for 6h. Continue to heat up to 115°C within 0.68h, keep for 12h, and finally cool down to 60°C within 0.56h;

[0035] (3) melt-spinning and drawing and winding the polyamide chips processed in step (2) to obtain flame-retardant polyamide fibers; the tempe...

Embodiment 2

[0038] A preparation method of flame retardant polyamide fiber, its specific process is as follows:

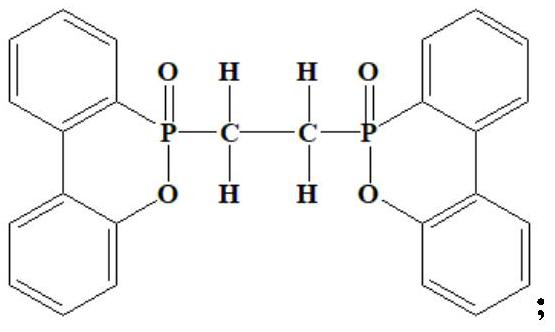

[0039] (1) 92 parts of nylon 66, 5 parts of melamine cyanurate, 0.5 parts of graphite-like carbon nitride, 0.5 parts of zinc diethylphosphinate and 2 parts of 9,10-dihydro-9-oxa- 10-phosphaphenanthrene-10-oxide derivatives are melt-blended to prepare flame-retardant polyamide chips, wherein the temperature of melt-blending is 260° C., 9,10-dihydro-9-oxa-10-phospha The structural formula of the phenanthrene-10-oxide derivative is:

[0040]

[0041] (2) Dry and pre-crystallize the flame retardant polyamide chips. The process is as follows: firstly, the temperature is raised from 15°C to 50°C within 0.5h, and the temperature is kept for 10h. Continue to heat up to 110°C within 0.5h, keep for 15h, and finally cool down to 50°C within 0.5h;

[0042] (3) melt-spinning and drawing and winding the polyamide chips processed in step (2) to obtain flame-retardant polyamide fibers; t...

Embodiment 3

[0045] A preparation method of flame retardant polyamide fiber, its specific process is as follows:

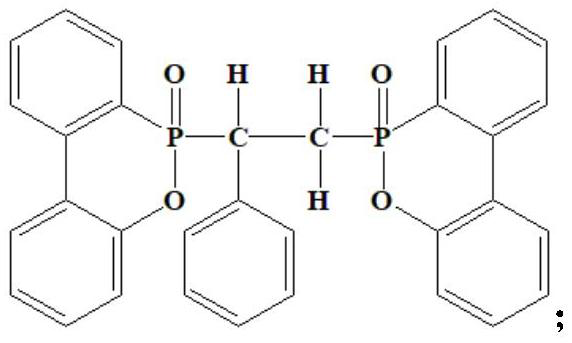

[0046] (1) 95.5 parts of nylon 56, 3 parts of melamine cyanurate, 0.4 parts of graphitic carbon nitride, 0.4 parts of zinc 2-carboxyethylphenylphosphinate and 1.7 parts of 9,10-dihydro-9 -Oxa-10-phosphaphenanthrene-10-oxide derivatives are melt-blended to obtain flame-retardant polyamide chips, wherein the temperature of melt-blending is 280°C, 9,10-dihydro-9-oxa- The structural formula of 10-phosphaphenanthrene-10-oxide derivatives is:

[0047]

[0048] (2) Dry and pre-crystallize the flame-retardant polyamide chips. The process is: first, the temperature is raised from 25 °C to 80 °C within 1 hour, and the temperature is kept for 5 hours. Continue to heat up to 120°C, keep for 8h, and finally cool down to 80°C within 1h;

[0049] (3) melt-spinning and drawing and winding the polyamide chips processed in step (2) to obtain flame-retardant polyamide fibers; the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com