Polyimide flame-retardant hook-and-loop fastener for fireman fire-extinguishing protective garment and manufacturing method thereof

A technology of polyimide and manufacturing method, which is applied in the field of fire-fighting equipment accessories, can solve problems such as low temperature resistance, non-conformity, melting, etc., and achieve good heat-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

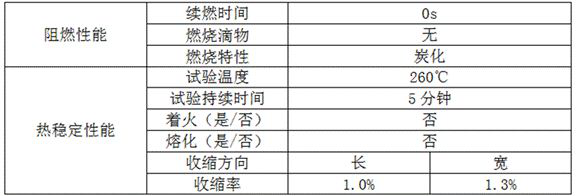

[0021] Example 1, a polyimide flame-retardant Velcro for firefighters to wear for fire protection, characterized in that the flame-retardant Velcro is prepared by interweaving polyimide filaments of appropriate specifications. The flame-retardant Velcro has a temperature resistance of 260 degrees Celsius. It will not melt and carbonize when it is burned.

[0022] A method for manufacturing a polyimide flame-retardant Velcro for firefighters' fire-fighting protective clothing, the method comprises the following steps:

[0023] (1) Raw material preparation: The raw material is polyimide filament, natural color or liquid coloring; there are at least 2 kinds of polyimide filaments of different specifications in the raw material, one of which is polyimide filament with a linear density of 180D , the other is polyimide filament with a linear density of 260D; and the breaking strength of polyimide filament is ≥3.0cN / dtex;

[0024] (2) Twisting and shaping processing: Twisting and sh...

Embodiment 2

[0026] Example 2, a kind of polyimide flame-retardant Velcro for firefighters to wear for fire protection: the flame-retardant Velcro is prepared by interweaving polyimide filaments of appropriate specifications. The flame-retardant Velcro has a temperature resistance of 260 degrees Celsius. It will not melt and carbonize when it is burned.

[0027] A method for manufacturing a polyimide flame-retardant Velcro for firefighters' fire-fighting protective clothing, the method comprises the following steps:

[0028] (1) Raw material preparation: The raw material is polyimide filament, natural color or liquid coloring; there are at least 2 kinds of polyimide filaments of different specifications in the raw material, one of which is polyimide filament with a linear density of 220D , the other is a polyimide filament with a linear density of 300D; and the breaking strength of the polyimide filament is ≥3.0cN / dtex;

[0029] (2) Twisting and shaping processing: Twisting and shaping th...

Embodiment 3

[0031] Example 3, a polyimide flame-retardant Velcro for firefighters' fire-fighting and protective clothing, the flame-retardant Velcro is prepared by interweaving black dope-colored polyimide filaments. The flame-retardant Velcro has a temperature resistance of 260 degrees Celsius. It will not melt and carbonize when it is burned.

[0032] The manufacture method of the polyimide flame-retardant Velcro for the firefighter's fire-fighting protective clothing comprises the following steps:

[0033] (1) Raw material preparation: 2 kinds of dope-colored black polyimide filaments; the linear densities are 200D and 280D respectively; the breaking strength of the polyimide filaments is 3.6cN / dtex.

[0034] (2) Twisting and shaping processing: Twist and shape the two kinds of dope-colored black polyimide filaments in step (1); the twisting degrees are as follows: the twisting range of 200D filaments is 280 twists / meters; the twist range of 280D filament twisting is 80 twists / meter;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com