Flame-retardant hook-and-loop fastener for fire-extinguishing protective clothing of firefighter and manufacturing method of flame-retardant hook-and-loop fastener

A manufacturing method and Velcro technology, which are used in flame-retardant fibers, protective devices against harmful chemicals, respiratory protection containers, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

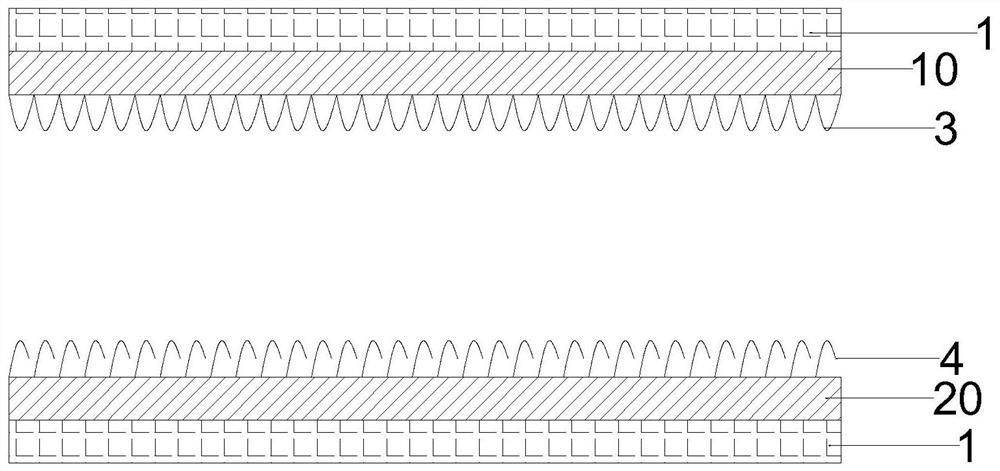

[0023] see figure 1 As shown, the technical solution to realize one of the objectives of the present invention is: a flame-retardant Velcro for firefighters' fire-fighting protective clothing, including a flame-retardant Velcro hook surface 10, a flame-retardant Velcro rough surface 20, wherein the flame-retardant Velcro Both the hook surface 10 and the flame-retardant hook surface 20 are prepared by interweaving PPS fibers and PET fibers, and the surface of the flame-retardant hook surface 10 is provided with several hooks 4, and the flame-retardant Velcro surface 20 A number of loops 3 are arranged on the surface, and the flame-retardant hook surface 10 and the back surface of the flame-retardant Velcro hair surface 20 are coated with a flame-retardant solid silica gel layer 1 .

[0024] The second technical solution to achieve the second purpose of the present invention is: a method for manufacturing fire-resistant protective clothing for firefighters, comprising the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com