Fire-fighting protective clothing fabric

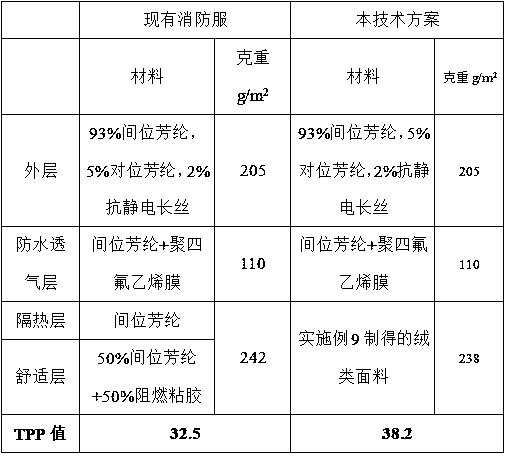

A technology for protective clothing and fabrics, applied in the field of fabrics, can solve problems such as TPP value and low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

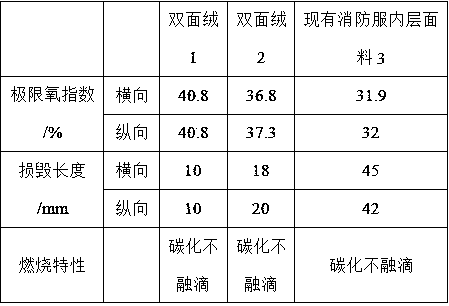

[0017] Embodiment 1, a fire-fighting protective clothing fabric, comprising an outer layer, a waterproof breathable layer and a comfortable heat-insulating layer, the comfortable heat-insulating layer is a velvet fabric, and the velvet fabric is a double-faced velvet fabric, double-faced velvet and Compared with single face fleece, it can store more air and improve the overall thermal insulation performance of the fabric. The double-sided velvet fabric is made of double-sided terry gray fabric after brushing, brushing, shearing, and shaping. The double-sided knitted velvet fabric has a softer feel. As the inner fabric of protective clothing, it is skin-friendly and comfortable; the double-sided terry gray fabric is made of The outer layer terry yarn, the inner layer terry yarn and the ground yarn are woven together according to parameters on the terry machine. The outer pile yarn constitutes the outer suede layer of the comfortable heat insulation layer connected with the wate...

Embodiment 2

[0018] Embodiment 2, according to the fire-fighting protective clothing fabric described in Embodiment 1, the base yarn is made of flame-retardant polyester filaments. Flame-retardant polyester has excellent physical and mechanical properties. It is woven into loops as the bottom yarn to ensure that the entire fleece fabric has high strength and stretchability, and ensures that the fabric does not deform when worn; and the melting point of flame-retardant polyester is low, which can be achieved by using existing shaping equipment. Shaping ensures that fleece fabrics have excellent dimensional stability and small washing shrinkage; however, flame-retardant polyester has the problem of melting and dripping, and contact with the skin after melting will cause skin burns.

Embodiment 3

[0019] Embodiment 3, according to the fire-fighting protective clothing fabric described in Embodiment 1, the outer loop yarn is polyimide yarn. In order to eliminate dripping on the cloth surface, the outer suede layer is made of polyimide yarn. When the polyimide yarn is weaving the gray cloth, a part of the polyimide yarn and the flame-retardant polyester filament are woven into loops at the same time, and the other part forms an elongated loop on the surface of the fabric. The settling arc is then brushed, sheared, and shaped to form the fluff on the surface of the inner fabric, which wraps the flame-retardant polyester filaments. The polyimide has no melting drop and small carbonization, which can eliminate the melting drop of the cloth surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com