Patents

Literature

35results about How to "Small washing shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

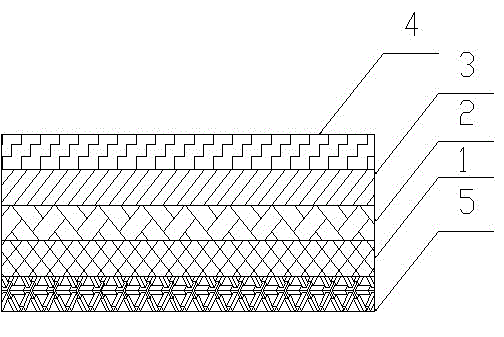

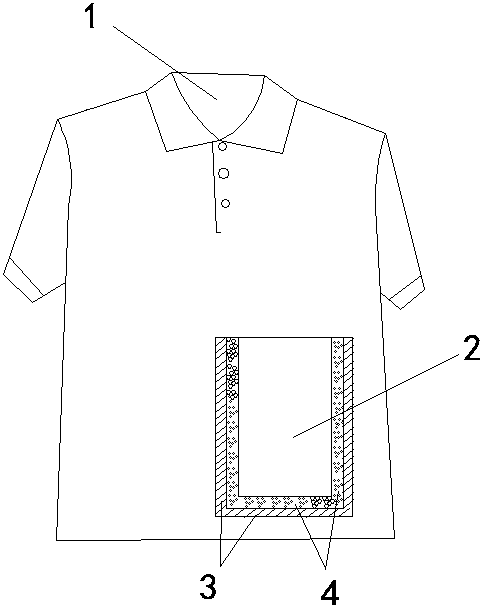

Waterproof antibacterial thermal fabric with good air permeability and comfortableness

InactiveCN105584126AGood warmth retentionGuaranteed warmthSynthetic resin layered productsWoven fabricsEngineeringViscose fiber

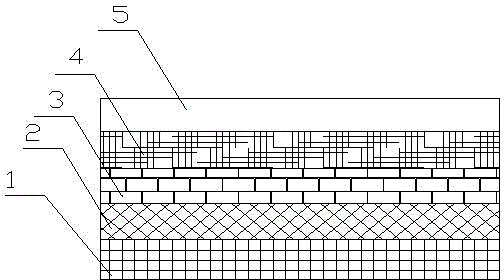

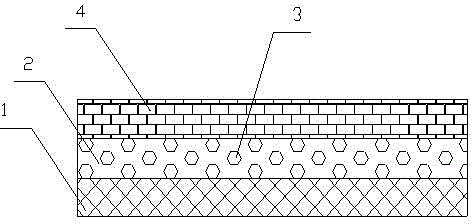

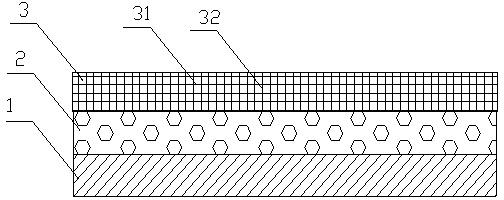

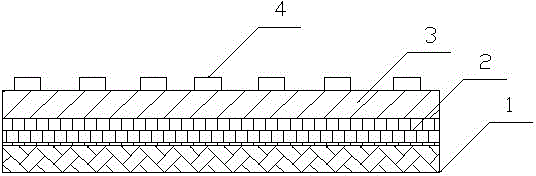

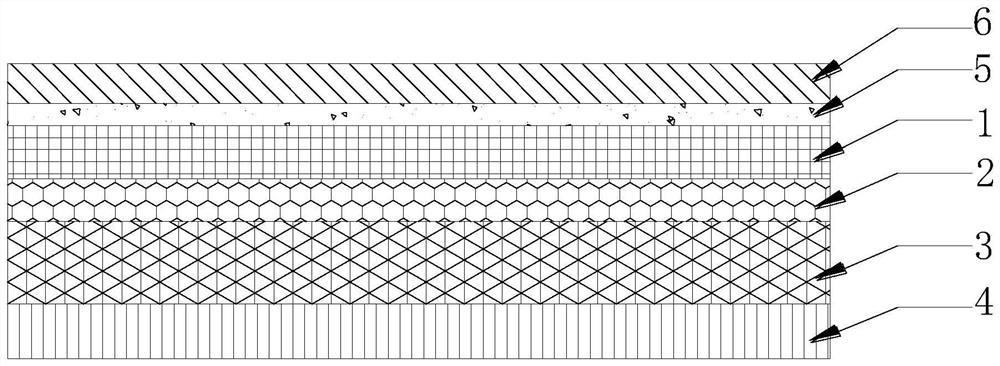

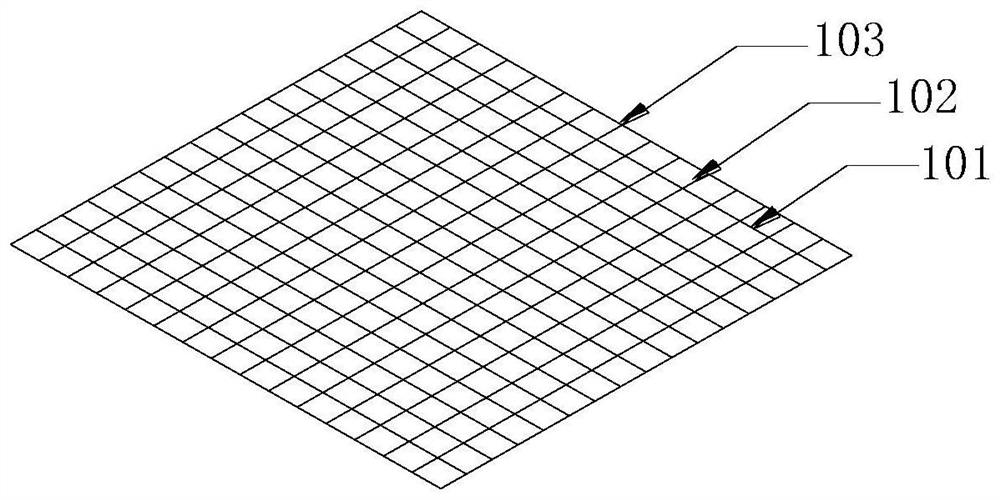

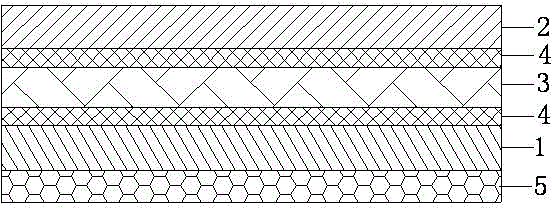

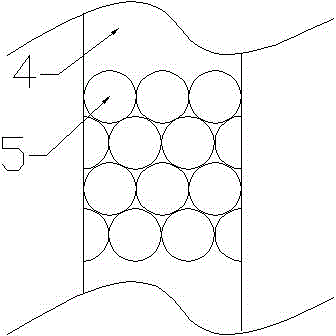

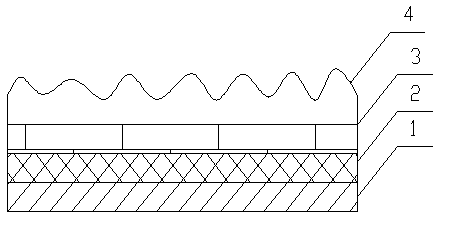

The invention relates to waterproof antibacterial thermal fabric with good air permeability and comfortableness. The fabric successively comprises a base layer (1), an inner layer (2), a fabric layer (3) and an outer layer (4) from the inside to the outside. The base layer (1) is prepared by interconnecting warp yarns and weft yarns. The warp yarns and the weft yarns are formed by weaving of nano-silver fiber. The inner layer (2) is a thermal layer. The outer layer (4) and the fabric layer (3) are pressed. The outer layer (4) is a windproof waterproof breathable film. The fabric layer (3) is textile. The textile is formed by 1 / 1 plain weaving of viscose fibers and silk. Filament diameter of the viscose fibers is 0.8-1.5 microns. According to the fabric, antibacterial efficiency can be enhanced. The fabric has good air permeability and comfortableness.

Owner:周忠平

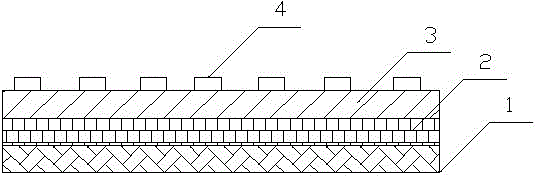

Antistatic, antibacterial, anti-radiation, breathable and comfortable fabric

The invention relates to an antistatic, antibacterial, anti-radiation, breathable and comfortable fabric. The fabric comprises a bottom layer (4); a basic layer (1) is laminated on the surface of the bottom layer, and is prepared by connecting warps and wefts; the warps and wefts are prepared by weaving nano silver fibers; and an aluminum alloy film (2) is adhered on the upper surface of the basic layer through adhesive and is provided with an antistatic layer (3), which is prepared by weaving warps and wefts; wherein the warps are made of cotton filaments, and the wefts are made of conductive fibers. The bottom layer is made of fabrics, which are made of viscose filaments and silks through 1 / 1 plain weave, and the diameter of single viscose filament is 0.8 to 1.5 [mu]m. The fabric is breathable and comfortable.

Owner:王世杰

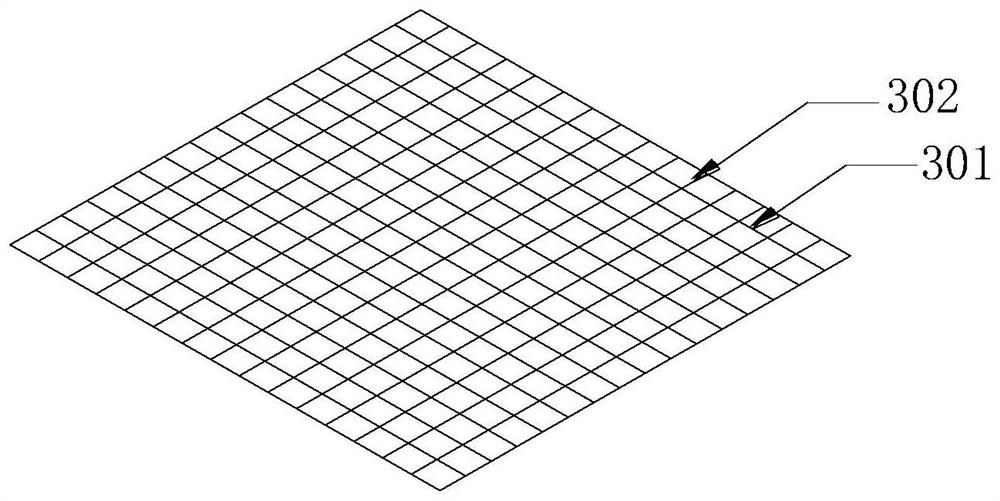

Anti-static breathable fabric with good comfort

InactiveCN104354350AImprove securityImprove performanceLayered productsWoven fabricsViscoseStatic performance

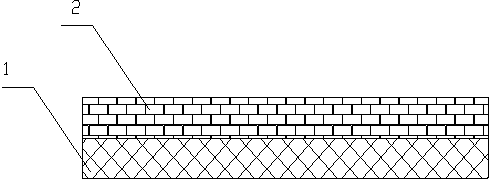

The invention relates to anti-static breathable fabric with good comfort. The fabric comprises a base layer (1), wherein an anti-static layer (2) is arranged on the surface of the base layer (1) and is formed by mutually weaving warp yarn and weft yarn, the warp yarn is made of cotton yarn, and the weft yarn is made of stripe-shaped conductive fibers arranged at intervals of 5-10 mm; and the base layer is prepared by textile fabric which is formed by viscose fibers and silk through 1 / 1 plain weave, and the monofilament diameter of each viscose fiber is 0.8 mu m-1.5 mu m. The fabric has good anti-static performance, breathability and comfort.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

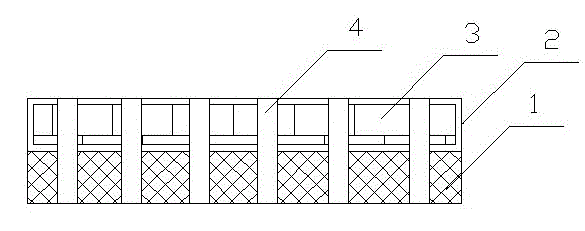

Flame-retardant fabric with good ventilation effect

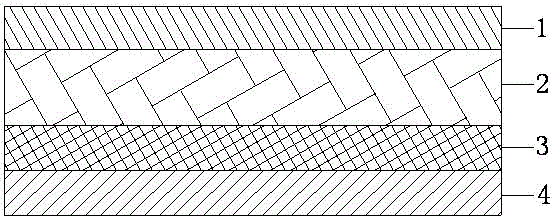

InactiveCN104799461AAnti-static hasSpecial rigidityCellulosic plastic layered productsWoven fabricsYarnViscose

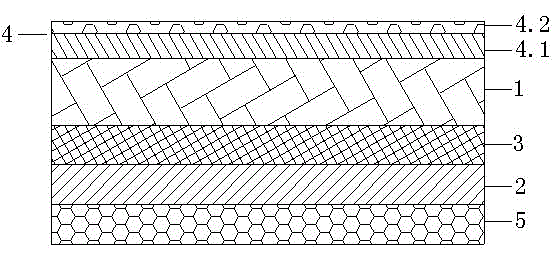

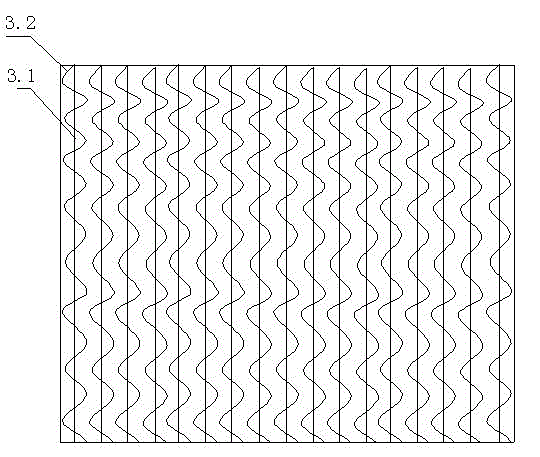

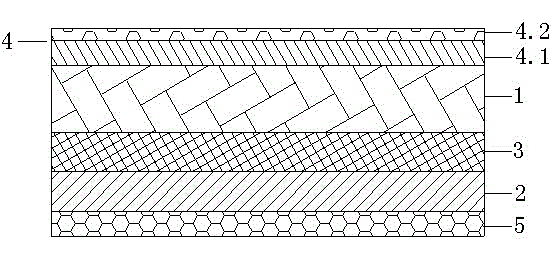

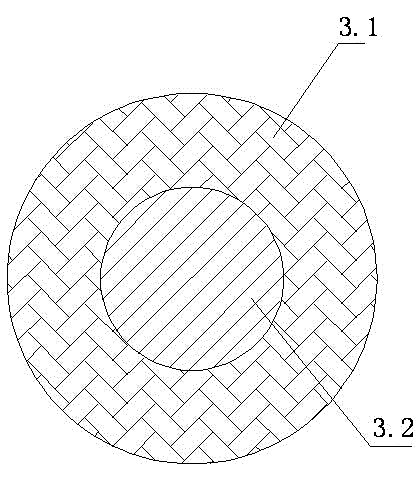

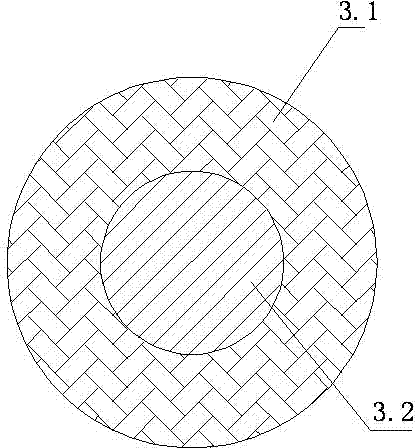

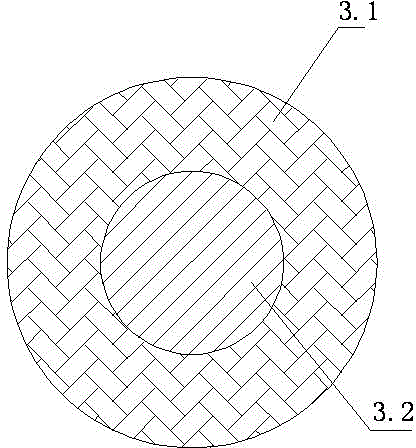

The invention relates to a flame-retardant fabric with a good ventilation effect. The flame-retardant fabric comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2); a base layer (5) is compounded on the lower surface of the lower cotton cloth layer; an anti-static layer (3) is further arranged between the upper cotton cloth layer (1) and the lower cotton cloth layer (2); the anti-static layer is made from core spun silk fiber; the fiber comprises yarns (3.1) and metal wires (3.2); the metal wires wind the yarns; the surface of the upper cotton cloth layer is covered by a flame-retardant coating layer (4); the flame-retardant coating layer comprises a flame-retardant polyurethane layer (4.1) at the bottom and an organic silicone oil layer (4.2) on the top; the base layer is made from textile; the textile is formed by plainly weaving viscose silks and natural silks at a ratio of 1:1; the monofilament diameter of the viscose silk is 0.8-1.5 microns. The flame-retardant fabric with the good ventilation effect is relatively low in cost, variable in bending, and good in ventilation effect.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Antistatic breathable fabric with good comfortableness

InactiveCN104369433AImprove use comfort performanceImprove the safety of useLayered productsClothingsAntistatic agentBiomedical engineering

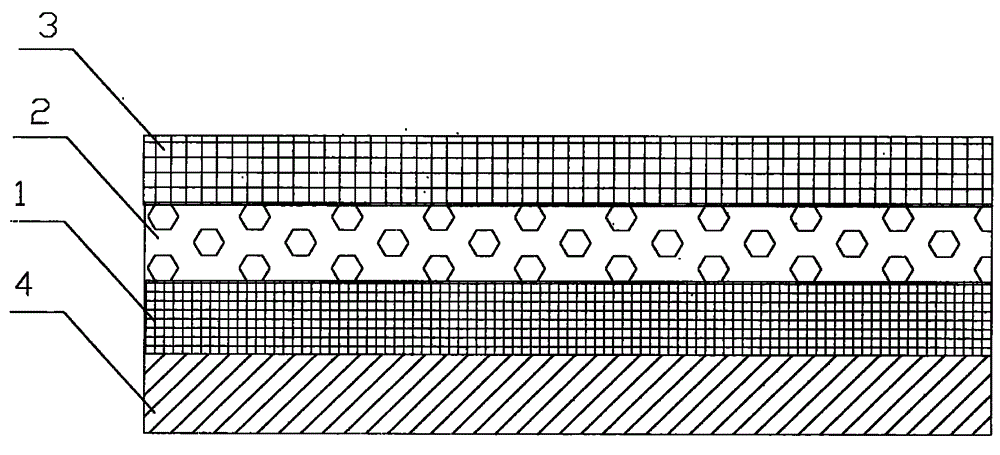

The invention relates to an antistatic breathable fabric with good comfortableness. The fabric comprises a base layer (1); a breathable layer (2) covers on the surface of the base layer (1); breathable holes (3) are arranged on the breathable layer; an antistatic layer (4) is adhered between the base layer (1) and the breathable layer; the antistatic layer comprises mutually woven warp yarn and weft yarns; and the warp yarn is made of cotton yarn, and the weft yarn is made of a striped conductive fiber conductive fiber with spacing of 5-10 mm. The base layer is made of fabric, the fabric is woven from viscose cellosilk and silk in 1 / 1 plain weave, and the viscose cellosilk has monofilament diameter of 0.8 to 1.5 mum. The fabric provided by the invention not only has breathable effect, but also has good antistatic performance and good comfortableness.

Owner:WUXI BALAS LIGHTING ELECTRONICS

Honeysuckle Jacquard fabric and preparation method thereof

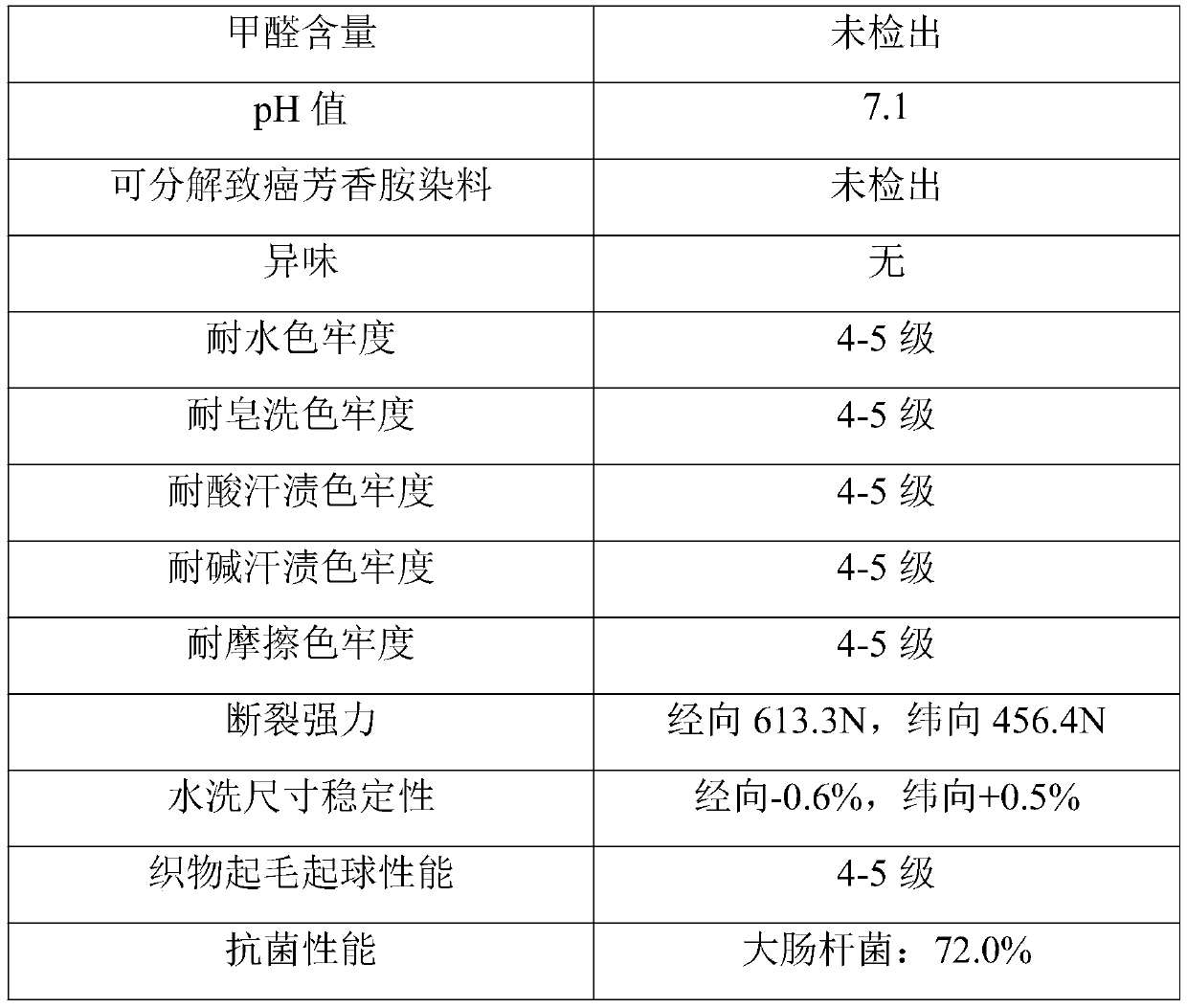

InactiveCN111118703AGive full play to the antibacterial health functionBright colorSwivel-woven fabricsLappet-woven fabricsYarnFiber

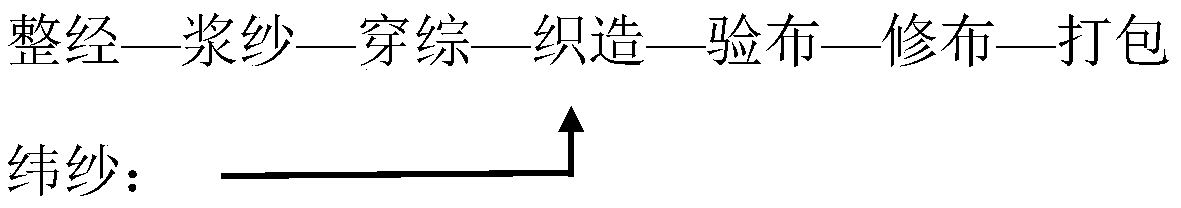

The invention provides a honeysuckle Jacquard fabric which is glossy, moisture-absorbent, breathable, soft and comfortable and has an antibacterial health function. The honeysuckle Jacquard fabric isprepared by interweaving 60s yarns of pure Tencel in warp direction and 40s compact Siro-spun yarns of pure honeysuckle fiber in weft direction. A preparation method of the honeysuckle Jacquard fabriccomprises a yarn production process, a weaving production process and bleaching and finishing processes. The honeysuckle Jacquard fabric prepared through the method is glossy, silky, soft, moisture-absorbent, breathable, comfortable and skin-friendly and has the antibacterial health function.

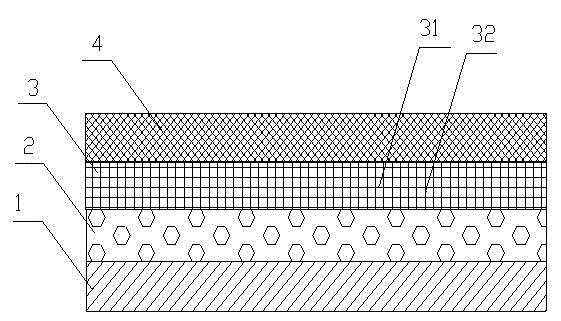

Antistatic and anti-radiation fabric with good breathability and comfortableness

InactiveCN104339742AImprove securityImprove performanceMetal layered productsMetallurgyViscose fiber

The invention relates to an antistatic and anti-radiation fabric with good breathability and comfortableness. The fabric comprises a base layer (1), wherein an aluminium alloy film (2) is bonded on the upper surface of the base layer (1); an antistatic layer (3) is arranged on the aluminium alloy film and is formed by interweaving warps (31) and wefts (32); the warps (31) are formed by cotton yarns; the wefts (32) are formed by stripe-shaped conductive fibers; the distance between the conductive fibers is 5-10mm; the base layer is made from a fabric; the fabric is formed by carrying out 1 / 1 plain weave on viscose silk and silk; the filament diameter of the viscose silk is 0.8-1.5mu m. The fabric has good antistatic and anti-radiation properties and has good breathability and comfortableness.

Owner:JIANGYIN ZEWAN TRADE

Velvet fabric with good air permeability and comfort

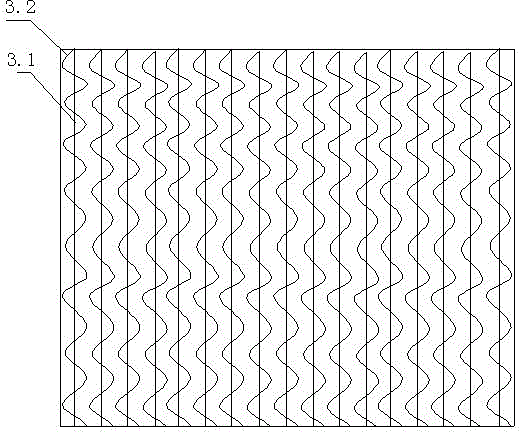

InactiveCN104783375AImproves breathability and comfortIncrease elasticityCellulosic plastic layered productsProtective garmentYarnEngineering

The invention relates to a velvet fabric with good air permeability and comfort. The velvet fabric comprises velvet cloth (1), a sponge layer (2) is arranged below the velvet cloth (1), and an anti-static layer (3) is arranged below the sponge layer (2). The anti-static layer (3) is composed of core-spun yarn fiber which comprises a yarn (3.1) and a metal yarn (3.2), wherein the yarn (3.1) is wound by the metal yarn (3.2). A base layer (4) is arranged below the anti-static layer (3). The base layer is made of a fabric which is formed by tatting viscose filaments and silk in a 1 / 1 tabby mode, wherein the monofilament diameter of the viscose filaments ranges from 0.8 microns to 1.5 microns. The velvet fabric is elegant in colored light, luxuriant, firm, resistant to abrasion, not prone to deformation, elastic, capable of absorbing humidity and breathable. The velvet fabric is good in air permeability and comfort.

Owner:JIANGYIN HONGWEI QINGSHAN SPINNING

Fabric having flame-retarding function and being good in moisture-absorbing property, breathability and comfort

InactiveCN105584172AReduce manufacturing costIn line with consumption levelSynthetic resin layered productsViscoseCotton cloth

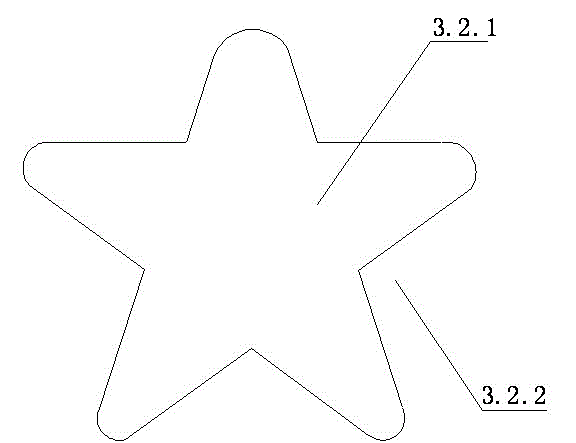

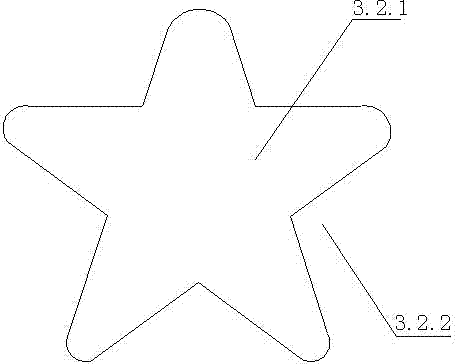

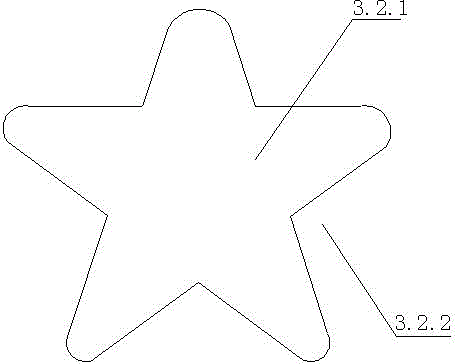

The invention relates to a fabric having a flame-retarding function and being good in moisture-absorbing property, breathability and comfort. The fabric includes an upper cotton cloth layer (1) and a lower cotton cloth layer (2). A base layer (5) is laminated to the upper cotton cloth layer (1). A moisture-absorbing layer (3) is arranged between the two cotton cloth layers and is formed by polyester fibers (3.1) and polyamide fiber (3.2) in a blended weaving manner, wherein a polyamide fiber cross section (3.2.1) of the polyamide fiber is in a five-pointed star shape. A groove (3.2.2) is formed between two adjacent angles of the five-pointed star shape. A flame-retarding coating (4) covers the surface of the upper cotton cloth layer (1). The base layer is formed from a fabric which is formed from viscose fiber filaments and silks in a 1 / 1 plain weave manner. The viscose fiber yarn is 0.8-1.5 [mu]m in monofilament diameter. The fabric is low in cost and is good in breathability and comfort.

Owner:李士清

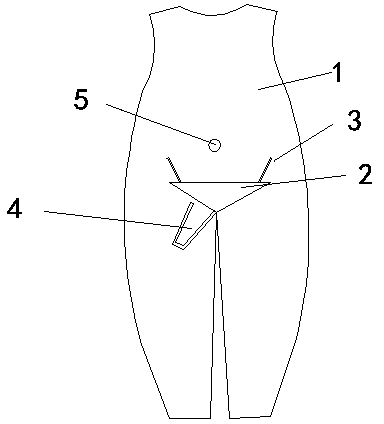

Breathable and comfortable garment with urine storage bag

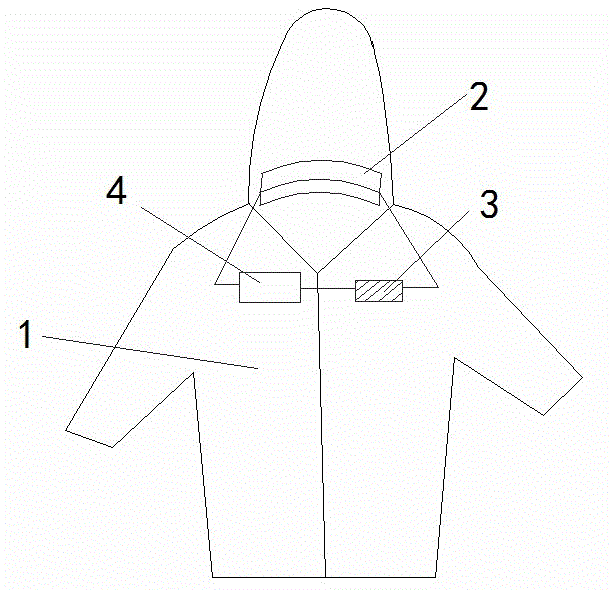

InactiveCN104336983AEasy urinationGood hygroscopicityProtective garmentSpecial outerwear garmentsMicrometerViscose

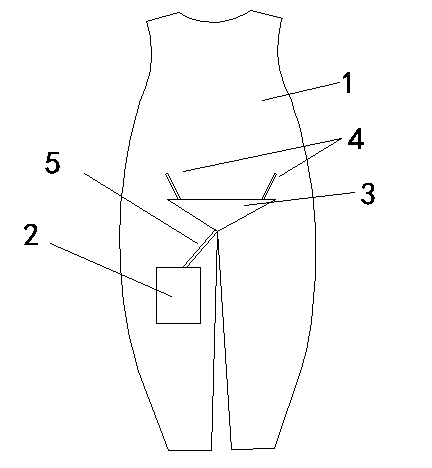

The invention relates to a breathable and comfortable garment with a urine storage bag. The breathable and comfortable garment comprises a garment body (1). The square urine storage bag (2) is arranged on one leg portion of the garment body (1). A triangular storage bag (3) is disposed on the crotch of the garment body (1). Two contraction bands (4) are disposed on the storage bag (3). The urine storage bag (2) and the storage bag (3) are connected through a guide tube (5). The garment body (1) is made of fabric. The fabric is formed by viscose filaments and silk through 1 / 1 plain weaving. The diameter of the single filament of the viscose filaments is 0.8-1.5 micrometers. When a worker is occupied in special work or a special person is inconvenient to go to the bathroom, the worker or the special person can urinate easily by wearing the breathable and comfortable garment, and awkwardness and discomfort can be avoided.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

Waterproof light-reflective artificial leather being good in breathability and comfort

InactiveCN104420320AExtended service lifeGood hygroscopicityLayered productsWoven fabricsSurface layerEngineering

The invention relates to waterproof light-reflective artificial leather being good in breathability and comfort. The artificial leather includes a base layer (1) and a surface layer (2) which are bonded to each other. A plastic film layer (3) is disposed on a surface of the surface layer (2). A plurality of light-reflective strips (4) are arranged on the plastic film layer (3). The base layer is manufactured from a fabric which is formed by viscose fiber silk and silk in a 1 / 1 plain weave manner. Diameter of single viscose fiber silk is 0.8-1.5 [mu]m. The artificial leather has a function of reflecting light beams. Meanwhile, by means of the plastic film layer for isolating other layers in the artificial leather from external environment, water cannot intrude into the other layers in the artificial leather, thereby prolonging a service life of the artificial leather. The artificial leather is good in breathability and comfort.

Owner:江苏红柳床单有限公司

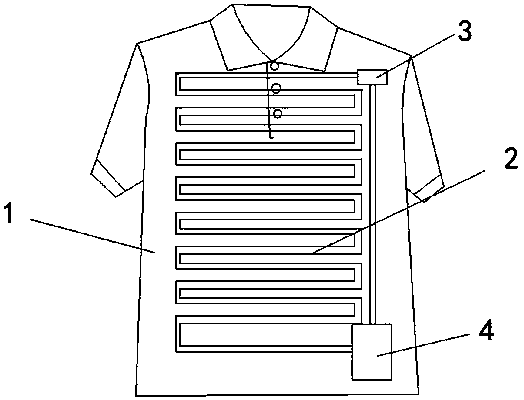

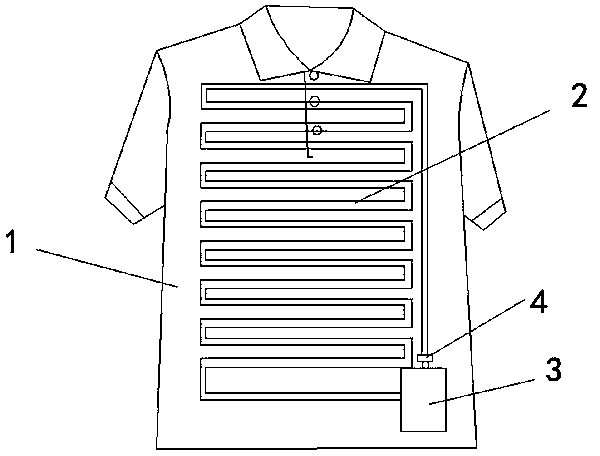

Well-breathable well-comfortable garment with function of lowering body temperature

InactiveCN104336782AReduce the temperatureSlow down the flowGarmentsWoven fabricsWhole bodyMicrometer

The invention relates to a well-breathable well-comfortable garment with a function of lowering body temperature. The well-breathable well-comfortable garment comprises a garment body (1). The whole garment body (1) is provided with a water guide tube (2); a pocket part of the garment body (1) is provided with a water pump (3); a front part of the garment body (1) is provided with a cooling box (4); the garment body (1) is made of shell fabric; the shell fabric is made by means of 1 / 1 plain weave of viscose yarns and silk yarns; the viscose yarns are 0.8 micrometer to 1.5 micrometers in diameter. The well-breathable well-comfortable garment has the advantages that the body temperature can be lowered, and the garment is good in breathability and comfortableness.

Owner:JIANGYIN JIADA ELECTRONICS TECH

Twisted yarn and production method thereof

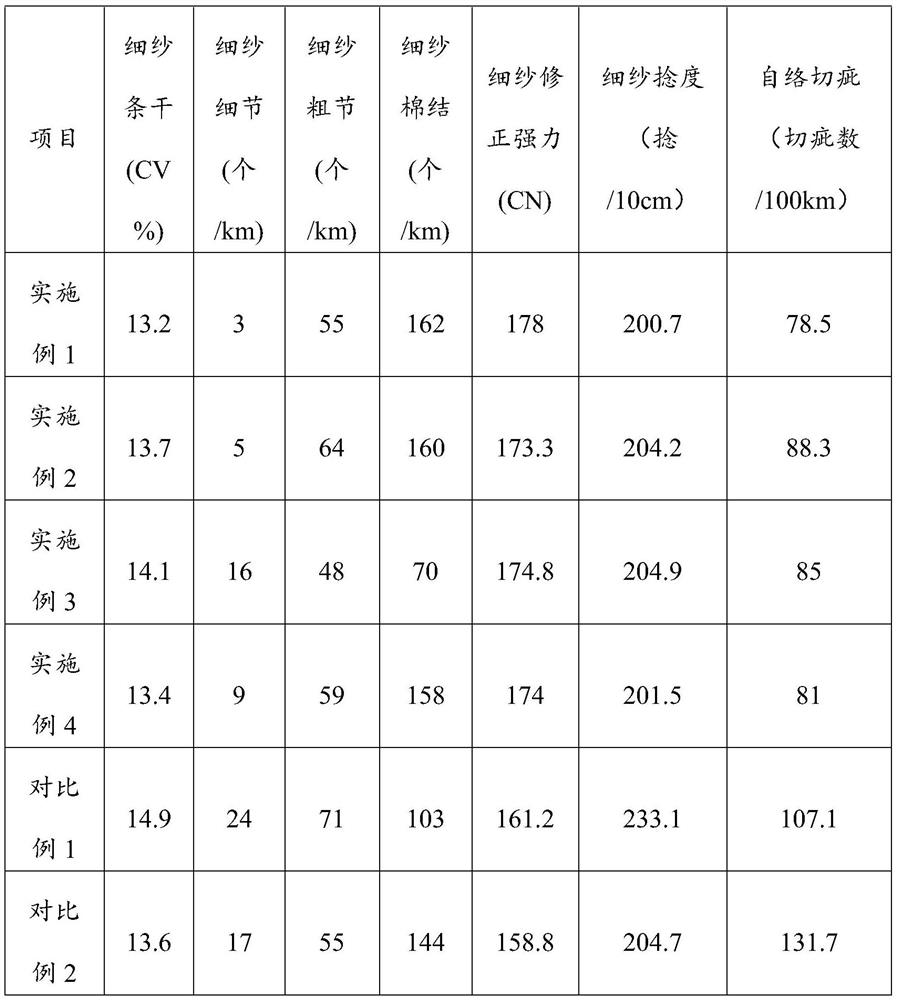

The invention discloses twisted yarn and a production method thereof, and belongs to the technical field of spinning. The production method of the twisted yarn comprises the following steps that cotton fibers serve as raw materials and are sequentially processed by a blowing procedure, a blowing-carding procedure, a combing procedure, a drawing procedure, a roving procedure, a spinning procedure and a spooling procedure to prepare the twisted yarn. The drawing procedure comprises the following step of carrying out twice combination, wherein 8 yarns are combined at the first time, and the dry weight ration is 15.2-18.6 g / 5 m; 6-8 yarns are combined at the second time, and the dry weight ration is 15-18.5 g / 5 m; and the spun yarn twist in the spinning procedure is 200-230 twists / 10 cm. The invention also discloses the twisted yarn obtained by the production method. The count of the twisted yarn is 60-80, and the strength of the twisted yarn can reach up to 178 CN.

Owner:JIHUA 3509 TEXTILE

Fabric with characteristics of static electricity resistance, radiation resistance, fire resistance, good gas permeation, and good comfort

InactiveCN105619960AImprove securityImprove performanceSynthetic resin layered productsMetal layered productsViscoseFire resistance

The present invention relates to a fabric with characteristics of static electricity resistance, radiation resistance, fire resistance, good gas permeation, and good comfort. The fabric comprises a base layer (1), wherein a layer of an aluminum alloy film (2) is adhered on the upper surface of the base layer, an antistatic layer (3) is arranged on the aluminum alloy film and is formed by mutually weaving warp yarns and weft yarns, the warp yarns are cotton yarns, the weft yarns are electric conduction fibers, a fireproof layer (4) is arranged on the outer surface of the antistatic layer, the base layer is made from a fabric, the fabric is formed by tatting viscose filaments and silk 1 / 1 plain, and the single filament diameter of the viscose filaments is 0.8-1.5 [mu]m. According to the present invention, the fabric has characteristics of good static electricity resistance, good radiation resistance, good fire resistance, good gas permeation, and good comfort.

Owner:苏光明

Breathable and comfortable garment capable of relieving fever

InactiveCN104336976ATo achieve the effect of physical coolingGood hygroscopicityGarment special featuresProtective garmentTemperature controlMicrometer

The invention relates to a breathable and comfortable garment capable of relieving fever. The breathable and comfortable garment capable of relieving fever comprises a garment body (1), wherein water guiding tubes (2) are distributed on the whole garment body (1); and a temperature controller (3) is arranged on a front piece of the garment body (1), consists of a power supply, a heater and a temperature-control circuit breaker, and is connected with the water guiding tubes (2) through a temperature-control valve (4). By the breathable and comfortable garment, a physical cooling effect can be achieved; the garment body is made of a fabric; the fabric is subjected to 1 / 1 plain weaving by viscose fibers and silk; and the diameter of each single viscose fiber is 0.8-1.5 micrometers. The garment is high in breathability and high in comfort level.

Owner:JIANGYIN JIANGDONG PLASTIC

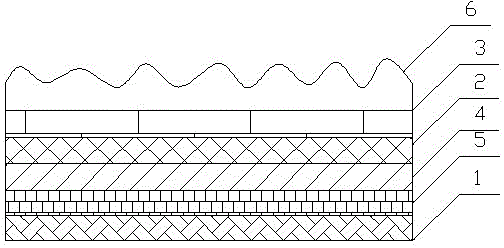

Anti-radiation heat-insulation artificial leather with good permeability and comfortableness

InactiveCN104420324AImprove fullnessTo keep warmLayered productsWoven fabricsPolymer scienceMetal fibers

The invention relates to anti-radiation heat-insulation artificial leather with good permeability and comfortableness, the artificial leather comprises a base layer (1), a foaming layer (2) and a surface layer (3) which are mutually bonded, a metal fiber layer (4) is arranged on external surface of the surface layer (3), suede (5) is arranged on interior surface of the base layer(1), the base layer is made by fabrics, the fabrics are made by plain weaving viscose filaments and silk according to ratio of 1: 1, and the diameter of monofilament of viscose filaments is 0.8mum-1.5mum. The artificial leather has heat-insulation effect and anti-radiation effect, and has advantages of good permeability and comfortableness.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

Anti-static breathable artificial leather being good in breathability and comfort

InactiveCN104420245AHas the function of conducting electricityImprove breathabilitySynthetic resin layered productsWoven fabricsPolymer scienceCarbon fibers

The invention relates to anti-static breathable artificial leather being good in breathability and comfort. The anti-static breathable artificial leather comprises, in a manner of being bonded to each other, a base material (1) and a plastic surface layer (2) in which a carbon fiber layer is embedded. Breathable pores (4) are formed in the artificial leather. The base material is manufactured from a fabric which is formed by viscose fiber silk and silk according in a 1 / 1 plain weave manner. Diameter of single viscose fiber silk is 0.8-1.5 [mu]m. The artificial leather has an anti-static effect and is enhanced in breathability. The artificial leather is good in breathability and comfort.

Owner:JIANGYIN BETTER TEXTILE

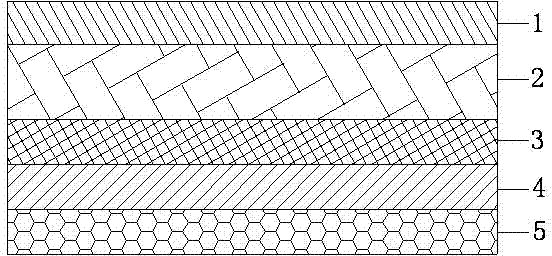

Moisture absorption and sweat releasing fabric with high air permeability and comfort

InactiveCN104770922APlay a breathable roleGood hygroscopicitySynthetic resin layered productsCellulosic plastic layered productsYarnViscose

The invention relates to a moisture absorption and sweat releasing fabric with high air permeability and comfort. The fabric comprises a pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged below the pure cotton fabric; a moisture absorption and sweat releasing layer (3) is further arranged below the bamboo charcoal fiber layer; the bottom of the moisture absorption and sweat releasing layer (3) is covered with a layer of blended fabric (4); the lower part of the blended fabric (4) is compounded with a substrate layer (5); the substrate layer is formed by a fabric, and the fabric is formed by the 1 / 1 plain weaving of viscose fiber yarns and silk; the filament diameter of the viscose fiber yarns is 0.8 to 1.5 microns. According to the moisture absorption and sweat releasing fabric with high air permeability and comfort, sweat can be absorbed away, and can be timely volatilized; the fabric is high in air permeability and comfort.

Owner:JIANGYIN HANXIN TEXTILE

Breathable and comfortable garment with urine guide tube

InactiveCN104337028ASolve urination problemsGood hygroscopicityProtective garmentSpecial outerwear garmentsContraction bandsButtocks

The invention relates to a breathable and comfortable garment with a urine guide tube. The breathable and comfortable garment comprises a garment body (1). A storage sleeve (2) is disposed on the crotch of the garment body (1). Two contraction bands (3) are disposed on the storage sleeve (2). The long soft guide tube (4) is arranged at the bottom of the storage sleeve (2). An opening (5) is formed in the buttock of the garment body. The soft guide tube (4) extends out of the garment through the opening (5). The garment body (1) is made of fabric. The fabric is formed by viscose filaments and silk through 1 / 1 plain weaving. The diameter of the single filament of the viscose filaments is 0.8-1.5 micrometers. When a patient after a surgery wears the breathable and comfortable garment, the contraction bands are tied to the thighs to fix the storage sleeve and the urine guide tube extends into a urine receiving container, the patient can urinate conveniently.

Owner:JIANGYIN KEHAO GARMENT & YARN DYE WEAVING

Anti-radiation antibacterial air-permeable comfortable fabric

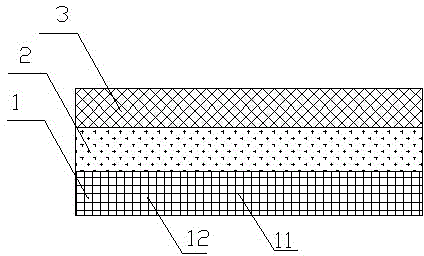

InactiveCN105563921AImprove radiation protection performanceImprove the protective effectProtective garmentMetal layered productsInterconnectionViscose fiber

The invention relates to an anti-radiation antibacterial air-permeable comfortable fabric. The fabric comprises a base layer (1); the base layer (1) is prepared through interconnection of warp yarns (11) and weft yarns (12); the warp yarns (11) and the weft yarns (12) are woven by nanosliver fibers; the upper surface of the base layer (1) is bonded with an aluminum alloy film (2); an antistatic layer (3) is arranged on the aluminum alloy film; the base layer is prepared from a fabric which is prepared by plain weaving of viscose fibers and silk according to a ratio of 1 / 1, and the diameter of a viscose fiber filament is 0.8 to 1.5 [mu]m. The anti-radiation antibacterial air-permeable comfortable fabric can shield radiation and effectively inhibit electrostatic discharge, and has good air permeability and a high comfort level.

Owner:冯爱华

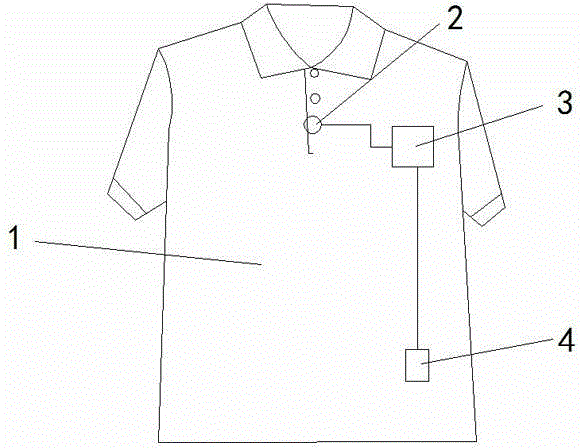

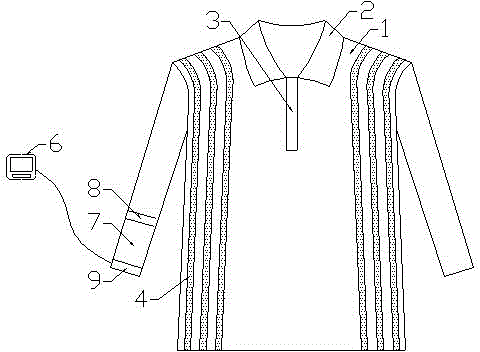

Breathable and comfortable garment with image pick-up function

InactiveCN104366781AGood hygroscopicityHigh strengthWoven fabricsProtective garmentMicrometerEngineering

The invention relates to a breathable and comfortable garment with an image pick-up function. The garment comprises a garment body (1). The front body of the garment body (1) is provided with a miniature camera (2). The upper pocket of the garment body (1) is provided with video equipment (3). The miniature camera (2) is connected with the video equipment (3) through a sensing wire. The lower pocket of the garment body (1) is provided with storage equipment (4). The garment body is made of fabric. The fabric is made by viscose fibers and silk through 1 / 1 plain weaving, and the single filament diameter of the viscose fibers is 0.8-1.5 micrometers. When a crime or an illegal event occurs, the video equipment records people breaking the law and the illegal event, records are then copied out from the storage equipment, and the records can be used as evidence for protecting victims. The garment is good in breathability and comfortableness.

Owner:JIANGYIN YASHUN GARMENT

Clothes with good air permeability, good comfort and refrigerator function

InactiveCN104323507AEffectively separate the temperatureImproves breathability and comfortGarment special featuresWoven fabricsMicrometerEngineering

The invention relates to clothes with good air permeability, good comfort and the refrigerator function. The clothes comprise a clothes body (1); a cylindrical object storage box (2) is fixedly arranged on a front body of the clothes body (1); a thermal insulating layer (3) is arranged on the periphery of the object storage box (2) and made of thermal insulating plastic; a freezing layer (4) is arranged inside the thermal insulating layer (3); the clothes body (1) is made of shell fabric; the shell fabric is formed by mucilage glue cellosilk and natural silk in a 1 / 1 plain weaving manner; and the monofilament diameter of the mucilage glue cellosilk ranges from 0.8 micrometer to 1.5 micrometers. When a person goes out, beverages or water bottles needing to be frozen are placed into the object storage box, the freezing layer will help to cool the beverages, the temperature of air will be effectively isolated through the thermal insulating layer, and therefore the function of freezing the beverages or water is achieved. The clothes are good in air permeability and comfort.

Owner:JIANGYIN TOPWAY TEXTILE

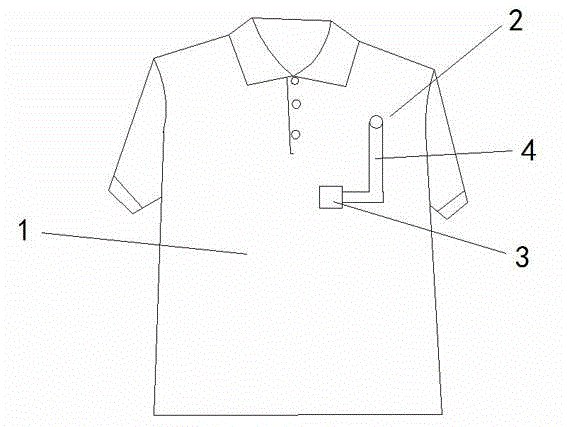

Permeable comfortable garment with mobile phone support

InactiveCN104366778AAvoid sorenessGood hygroscopicityWoven fabricsProtective garmentMicrometerViscose

The invention relates to a permeable comfortable garment with a mobile phone support. The garment comprises a garment body (1); the front portion of the garment body (1) is provided with a plastic gear (2) connected to a support (4), and the support (4) is connected to a mobile phone support (3). The garment body (1) is made of a fabric by weaving viscose fibers and silks in 1 / 1 plain structures, and the diameter of a monofilament of the viscose fibers ranges from 0.8 micrometer to 1.5 micrometer. When the arm is sore since a user holds and uses a mobile phone for a long term, the user is capable of placing the mobile phone on the support and adjusting the support into the proper position, the hands can be released, pain is avoided, and the permeability and comfortableness are high.

Owner:WUXI BALAS LIGHTING ELECTRONICS

Anti-radiation light-reflecting artificial leather being good in breathability and comfort

InactiveCN104420253APlay the role of radiation protectionGood hygroscopicityCellulosic plastic layered productsGlass/slag layered productsSurface layerMetal fibers

The invention relates to anti-radiation light-reflecting artificial leather being good in breathability and comfort. The artificial leather includes a base layer (1) and a surface layer (2), which are bonded to each other. A metal fiber layer (3) is formed on a surface of the surface layer (2). A plurality of reflective stripes (4) are disposed on the metal fiber layer (3). The base material is manufactured from a fabric which is formed by viscose fiber silk and silk according in a 1 / 1 plain weave manner. Diameter of single viscose fiber silk is 0.8-1.5 [mu]m. The artificial leather has a function of reflecting light and meanwhile has an effect of radiation resistance, and is good in breathability and comfort.

Owner:JIANGSU HENGDA CASHMERE CLOTHING TECH

Fireproof suit fabric with good air permeability

PendingCN114714697AImprove breathabilityHigh strengthChemical protectionHeat protectionPolyesterMoisture absorption

The invention relates to the technical field of fireproof suit fabrics, in particular to a fireproof suit fabric with good air permeability. The invention aims to solve the technical problems that the tensile strength and the comfort degree are poor, the moisture absorption and air permeability of the fabric are better, and the fabric cannot resist static electricity. In order to solve the technical problems, the fireproof suit fabric with the good air permeability comprises a base layer, the bottom face of the base layer is sequentially and fixedly connected with a wear-resisting layer, a moisture absorption layer and a fluff layer from top to bottom, and the top face of the base layer is sequentially and fixedly connected with a fireproof layer and a waterproof layer from bottom to top; the wear-resistant layer formed by blending the aramid fibers and the memory fiber polyester is high in strength, durable, not prone to abrasion and small in washing shrinkage rate, the fabric is soft, has a good crease-resistant function and rebound resilience and has high wearing comfort, the moisture absorption layer guarantees the sweat absorption performance of the fabric, meanwhile, the fabric has good breathability, and the fabric is comfortable to wear and comfortable to wear. The fabric can be worn in a long-term high-temperature environment and can prevent rainwater and snow from invading.

Owner:许得法

Antiskid impact-resistant artificial leather being good in breathability and comfort

InactiveCN104420303AStrong impact resistanceIncrease coefficient of frictionLayered productsWoven fabricsPolymer sciencePolymer chemistry

The invention relates to antiskid impact-resistant artificial leather being good in breathability and comfort. The artificial leather includes a base material (1), a first foaming layer (2) and a surface compact layer (3). The first foaming layer (2) is fixedly stuck on an inner surface of the surface compact layer (3). The base layer is arranged on one side, which is opposite to the surface compact layer (3), of the first foaming layer (2). A second foaming layer (4) and an impact-resistant layer (5) are arranged between the base material (1) and the first foaming layer (2). A plastic membrane layer (6) is arranged on an outer surface of the surface compact layer (3). The base material is manufactured from a fabric which is formed by viscose fiber silk and silk in a 1 / 1 plain weave manner. Diameter of single viscose fiber silk is 0.8-1.5 [mu]m. The artificial leather is prolonged in service life, is enhanced in antiskid performance and is good in breathability and comfort.

Owner:JIANGYIN MINGPIN KNITTING

Hygroscopic bamboo charcoal fiber fabric with good air permeability and high comfort level

InactiveCN104786580AImprove breathabilityGood hygroscopicitySynthetic resin layered productsCellulosic plastic layered productsEngineeringNonwoven fabric

The invention relates to a hygroscopic bamboo charcoal fiber fabric with good air permeability and high comfort level. The hygroscopic bamboo charcoal fiber fabric comprises bamboo charcoal fibers (1), wherein a base layer (5) is laminated below the bamboo charcoal fibers; a non-woven fabric layer (2) covers the bamboo charcoal fibers; a moisture absorbing layer (3) is further arranged between the non-woven fabric layer and the bamboo charcoal fibers; the base layer is prepared from a fabric formed by tabbing viscose cellosilk and silk in a 1 / 1 tabby manner; the monofilament diameter of the viscose cellosilk is 0.8 microns to 1.5 microns. The hygroscopic bamboo charcoal fiber fabric with the good air permeability and the high comfort level is good in air permeability, can absorb sweat, enables sweat to evaporate in time, and is high in comfort level.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Sweat-absorbent garment with good air permeability and good comfort and capable of prompting through color change

InactiveCN105559171AAchieve internal and external ventilationEasy dischargeProtective garmentSpecial outerwear garmentsDisplay deviceEngineering

The invention relates to a sweat-absorbent garment with good air permeability and good comfort and capable of prompting through color change. The sweat-absorbent garment includes a garment body (1), a setting device (6), a prompting display device, and a prompting control device (9); a plurality of bar-shaped grooves (4) are longitudinally arranged in two sides of a front sheet of the garment body (1); holes (5) are densely arranged in the bar-shaped grooves (4); and the garment body is made of fabric, the fabric is plain-woven by 1 / 1 of viscose fiber silk and natural silk, and the diameter of the viscose fiber silk is 0.8-1.5 [mu]m. The sweat-absorbent garment can prompt the severity of a matter through color change of a color-changeable display, and the sweat-absorbent garment is good in air permeability and comfort.

Owner:沈卫军

Waterproof antiskid artificial leather with good air permeability and comfortableness

InactiveCN104389188AIncrease coefficient of frictionEasy to holdSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceEngineering

The invention relates to waterproof antiskid artificial leather with good air permeability and comfortableness. The artificial leather comprises a base material (1), a foaming layer (2) and a surface layer (3) which are arranged successively from the inside out. The outside surface of the surface layer (3) is provided with a plastic film layer (4) which is a PVC plastic layer with a concavo-convex surface. The base material is prepared from fabric which is formed by 1 / 1 plain weaving of viscose fiber filaments and silk. Diameter of a single viscose fiber filament is 0.8-1.5 microns. The other material layers of the artificial leather are isolated from the outside world through the plastic film layer, and water cannot infiltrate into the other material layers of the artificial leather. Thus, service life of a product is prolonged. As the plastic layer is a PVC plastic layer with a concavo-convex surface, friction coefficient of the artificial leather surface can be enhanced. Thus, an antiskid capability of the artificial leather is improved. The artificial leather is easy for human hands to hold, and a using effect of the artificial leather is guaranteed. The artificial leather provided by the invention has good air permeability and comfortableness.

Owner:JIANGYIN YAOSAI RONGDE CRAFT GLASS SHOP

Garment with neck massage function and excellent breathability and comfort

InactiveCN104366830ARelax neck musclesRelax musclesGarment special featuresWoven fabricsCervical spondylosisMicrometer

The invention relates to a garment with a neck massage function and excellent breathability and comfort. The garment comprises a garment body (1). A neck of the garment body (1) is provided with a latex massage strip (2) with bumps, the latex massage strip (2) is connected with a control module (3), the control module (3) is a single chip microcomputer and is connected with a power module (4), the garment body is made of fabrics, viscose fibers and silk are subjected to 1 / 1 plain weave to form the fabrics, and the diameter of each single filament of each viscous fiber ranges from 0.8 micrometer to 1.5 micrometers. The garment has the advantages that a switch of the power module can be turned on when a wearer feels tired, so that the single chip microcomputer can be powered up, the latex massage strip can run according to programs in the single chip microcomputer, the acupuncture points of the neck of the wearer can be stimulated by the bumps, the neck of the wearer can be massaged, an effect of relaxing the muscles of the neck of the wearer can be realized, and cervical spondylosis can be prevented; the garment is excellent in breathability and comfort.

Owner:WUXI BALAS LIGHTING ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com