Twisted yarn and production method thereof

A production method and technology of twisted yarn, which is applied in yarn, textile and papermaking, etc., can solve the problems of difficult to obtain spun twisted yarn, cannot obtain strong twisted yarn, increase spun yarn breakage, etc., and achieve small washing shrinkage, air permeability and moisture absorption Good performance, smooth and comfortable feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

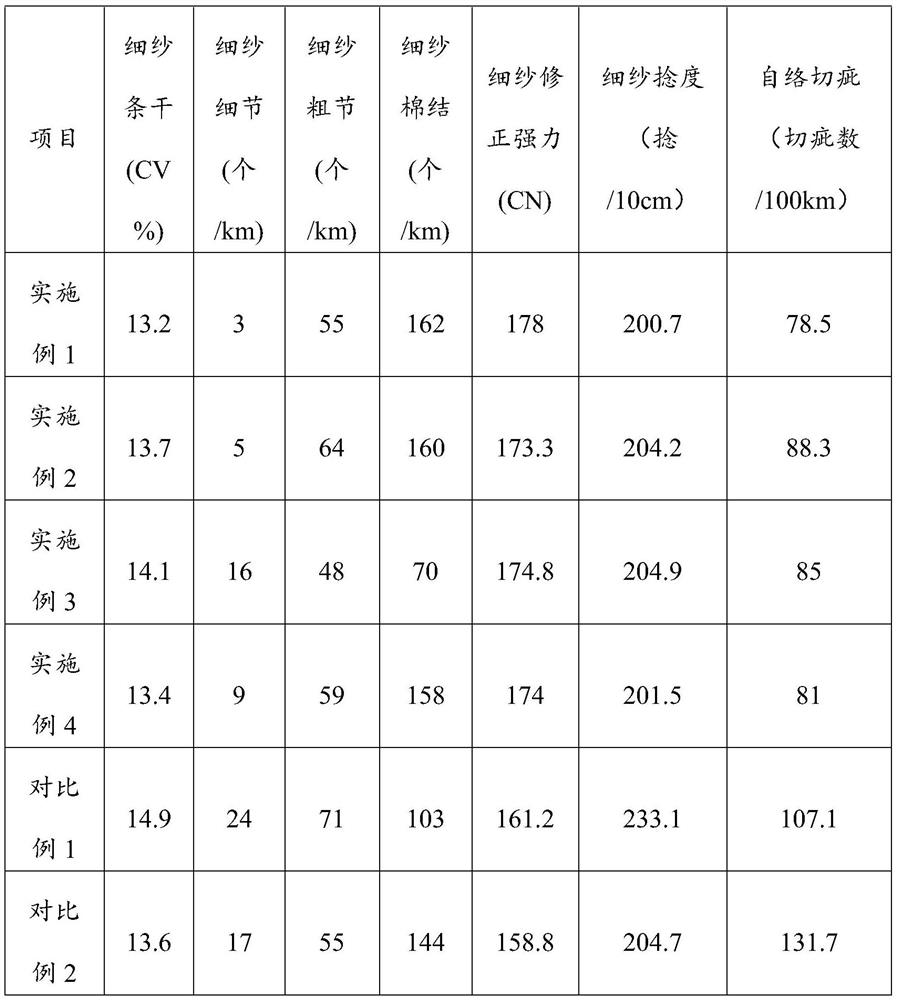

Examples

Embodiment 1

[0031] The present embodiment proposes a kind of production method of twisted yarn, comprises the following steps:

[0032] Cotton fibers are used as raw materials to be processed in turn through the cleaning process, carding process, combing process, drawing process, roving process, spun yarn process and winding process; in the cotton fiber, calculated according to the mass percentage, by 80% Xinjiang fine-staple cotton and 20% Brazilian cotton;

[0033] In the cleaning and carding process, the feeding plate and the licker-in rollers have a spacing of 12 inches, and the cylinder and the cover plate have a 5-point spacing of 8 inches × 7 inches × 7 inches × 7 inches × 8 inches. The entrance distance between the roller and the small drain bottom is 8mm, and the exit distance is 2mm; the carding dry weight is 19.2g / 5m;

[0034] In the combing process, the combed dry weight is quantitatively 18.9g / 5m, and the combed noil rate is controlled within 15%;

[0035] Wherein, the draw...

Embodiment 2

[0040] The production method of this embodiment is basically the same as that of Example 1, except that the twist direction in the spinning process is S twist, and JC9.7tex single yarn with tight S twist and strong twist is produced, and the single yarn is high-count strong twist yarn.

Embodiment 3

[0042] The present embodiment proposes a kind of production method of twisted yarn, comprises the following steps:

[0043]Cotton fibers are used as raw materials to be processed in turn through the cleaning process, carding process, combing process, drawing process, roving process, spun yarn process and winding process; in the cotton fiber, calculated according to the mass percentage, by 80% Xinjiang fine-staple cotton and 20% Xinjiang long-staple cotton;

[0044] In the cleaning and carding process, the feeding plate and the licker-in rollers have a spacing of 12 inches, and the cylinder and the cover plate have a 5-point spacing of 8 inches × 7 inches × 7 inches × 7 inches × 8 inches. The entrance distance between the roller and the small drain bottom is 8mm, and the exit distance is 2mm; the carding dry weight is 19.2g / 5m;

[0045] In the combing process, the dry weight of combed Xinjiang fine-staple cotton is quantitatively 19g / 5m, and the dry weight of combed Xinjiang l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Powerful | aaaaa | aaaaa |

| Powerful | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com