A method for preventing and extinguishing fire by injecting nitrogen into the full-section curtain of goaf in U-shaped ventilation working face

A goaf and working face technology, applied in the direction of fire prevention, dust prevention, mining equipment, etc., can solve the problems of uneven distribution, large air leakage in goaf, and small nitrogen diffusion radius.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

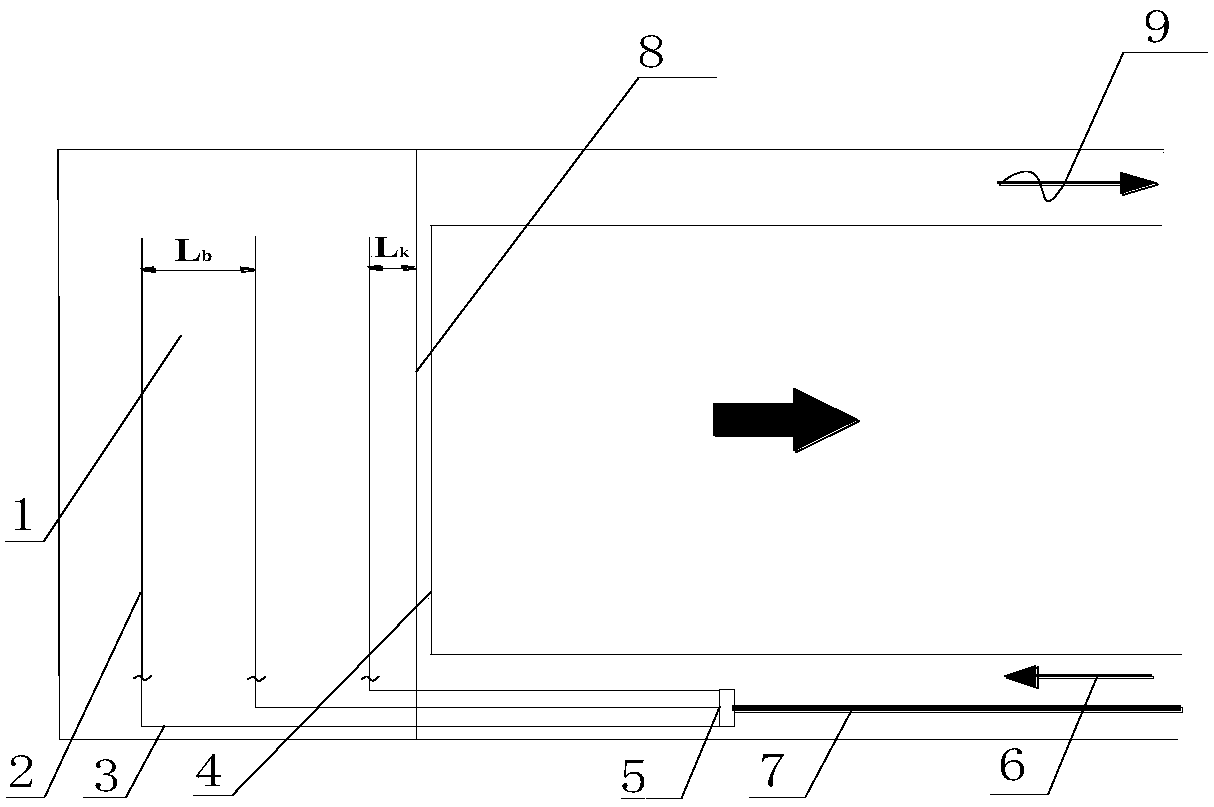

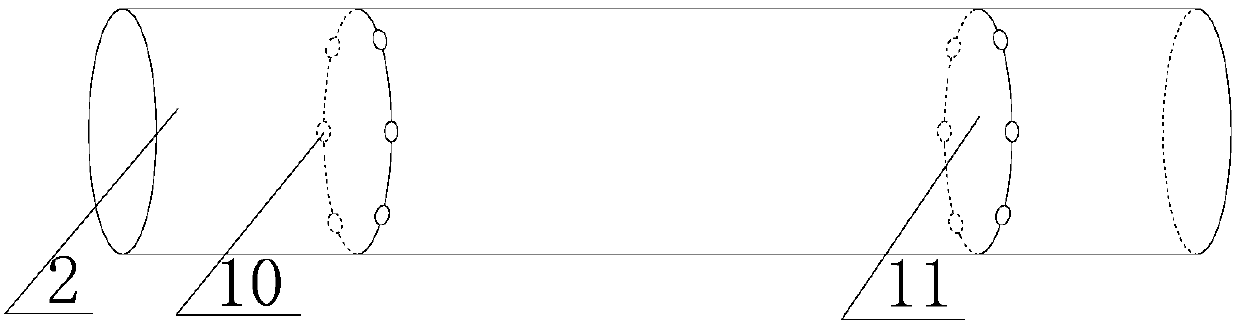

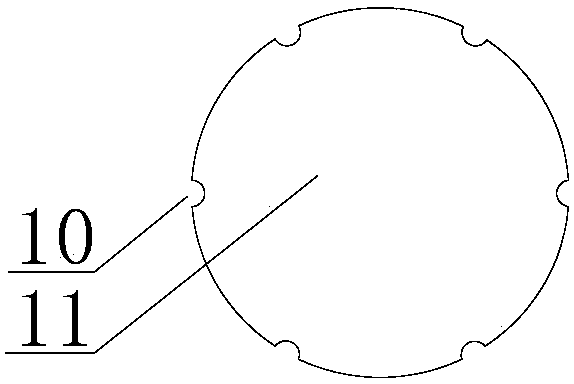

[0036] see figure 1 , figure 2 A method for preventing and extinguishing fires by injecting nitrogen into the full-section curtain of a U-shaped ventilated working face goaf, comprising: determining the amount of nitrogen injected according to the provisions of Article 7.1 of "Technical Specifications for Fire Prevention and Extinguishment with Nitrogen in Coal Mine" (MT / T701-1997), Specifically:

[0037]

[0038] Among them, Q 0 — Air leakage in the goaf oxidation zone, m 3 / min; Generally, it is selected according to 1 / 60-1 / 100 of the air volume of the working face; after taking measures to plug the air leakage, the air leakage volume is estimated in the oxidation zone of the goaf;

[0039] C 1 - the average oxygen concentration in the gob oxidation zone, %;

[0040] C 2 —Inerting fire protection index of goaf, its value is the critical oxygen concentration of coal spontaneous combustion, %;

[0041] C N —Nitrogen concentration of injected nitrogen, %;

[0042] ...

no. 2 example

[0046] see figure 1 , figure 2 A method for preventing and extinguishing fires by injecting nitrogen into the full-section curtain of a U-shaped ventilated working face goaf, comprising: determining the amount of nitrogen injected according to the provisions of Article 7.1 of "Technical Specifications for Fire Prevention and Extinguishment with Nitrogen in Coal Mine" (MT / T701-1997), Specifically:

[0047]

[0048] Among them, Q 0 — Air leakage in the goaf oxidation zone, m 3 / min; Generally, it is selected according to 1 / 60-1 / 100 of the air volume of the working face; after taking measures to plug the air leakage, the air leakage volume is estimated in the oxidation zone of the goaf;

[0049] C 1 - the average oxygen concentration in the gob oxidation zone, %;

[0050] C 2 —Inerting fire protection index of goaf, its value is the critical oxygen concentration of coal spontaneous combustion, %;

[0051] C N —Nitrogen concentration of injected nitrogen, %;

[0052] ...

no. 3 example

[0057] see figure 1 , figure 2 A method for preventing and extinguishing fires by injecting nitrogen into the full-section curtain of a U-shaped ventilated working face goaf, comprising: determining the amount of nitrogen injected according to the provisions of Article 7.1 of "Technical Specifications for Fire Prevention and Extinguishment with Nitrogen in Coal Mine" (MT / T701-1997), Specifically:

[0058]

[0059] Among them, Q 0 — Air leakage in the goaf oxidation zone, m 3 / min; Generally, it is selected according to 1 / 60-1 / 100 of the air volume of the working face; after taking measures to plug the air leakage, the air leakage volume is estimated in the oxidation zone of the goaf;

[0060] C 1 - the average oxygen concentration in the gob oxidation zone, %;

[0061] C 2 —Inerting fire protection index of goaf, its value is the critical oxygen concentration of coal spontaneous combustion, %;

[0062] C N —Nitrogen concentration of injected nitrogen, %;

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com