Self-adaptive inner wall robot for pipeline

A pipeline robot and self-adaptive technology, applied to special pipes, pipe components, mechanical equipment, etc., can solve problems such as stuck, inconvenient manual maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

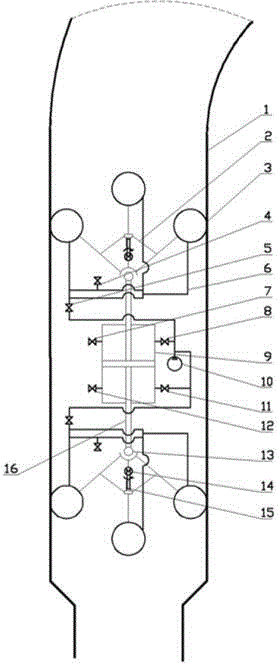

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] An adaptive inner wall pipeline robot, the pipeline robot is composed of three sections, the middle part is a cylinder 9, and both ends are airbag running mechanisms; the cylinder 9 is divided into upper and lower two independent cavities, and the airbag running mechanism passes Hinge 13, piston rod 16 link to each other with cylinder 9; Described air bag traveling mechanism comprises connecting rod mechanism 2, air bag 3, stepper motor 14 and screw rod pair 15, and described connecting rod mechanism 2 one ends are threadedly connected with air bag 3, and the other end is connected with air bag 3. The screw pair 15 is hinged, and the screw pair 15 is connected to the stepper motor 14 through a coupling; the outside of the cylinder 9 is provided with an air pump 10, and the cylinder 9 and the air pump 10 are threaded, and the cylinder 9 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com