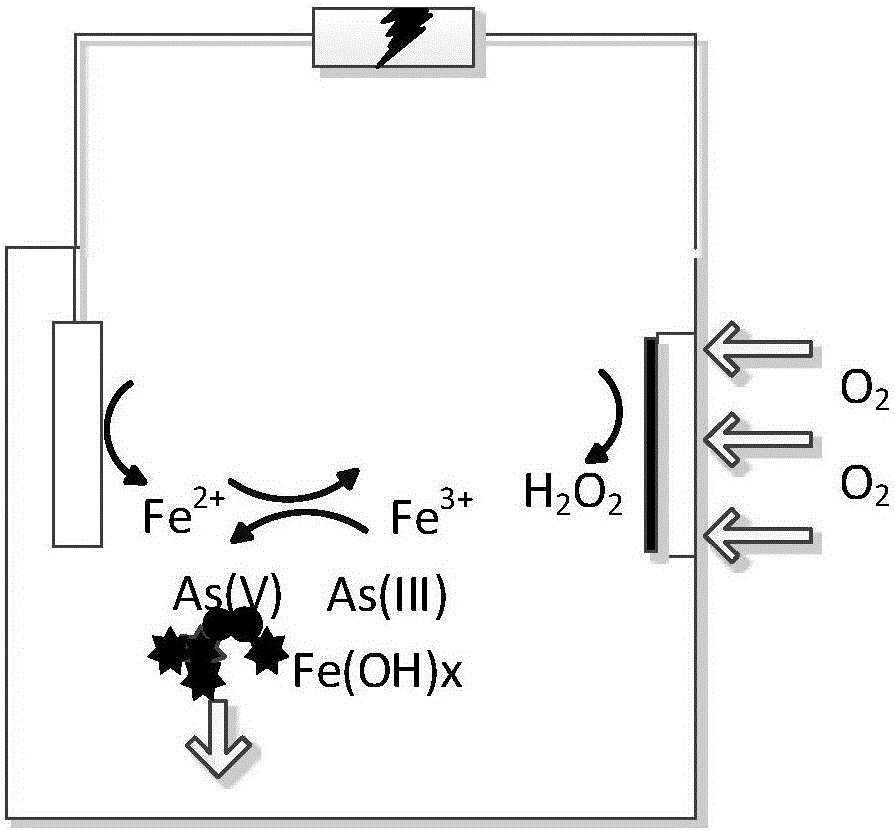

Low energy consumption device and method for removal of arsenic from water by electrochemistry coordinated oxidation-flocculation

A synergistic oxidation and electrochemical technology, applied in the field of water pollution remediation, can solve the problems of high energy consumption of electrode reaction and high cost of pre-oxidation, and achieve the effect of saving system energy consumption and eliminating aeration links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

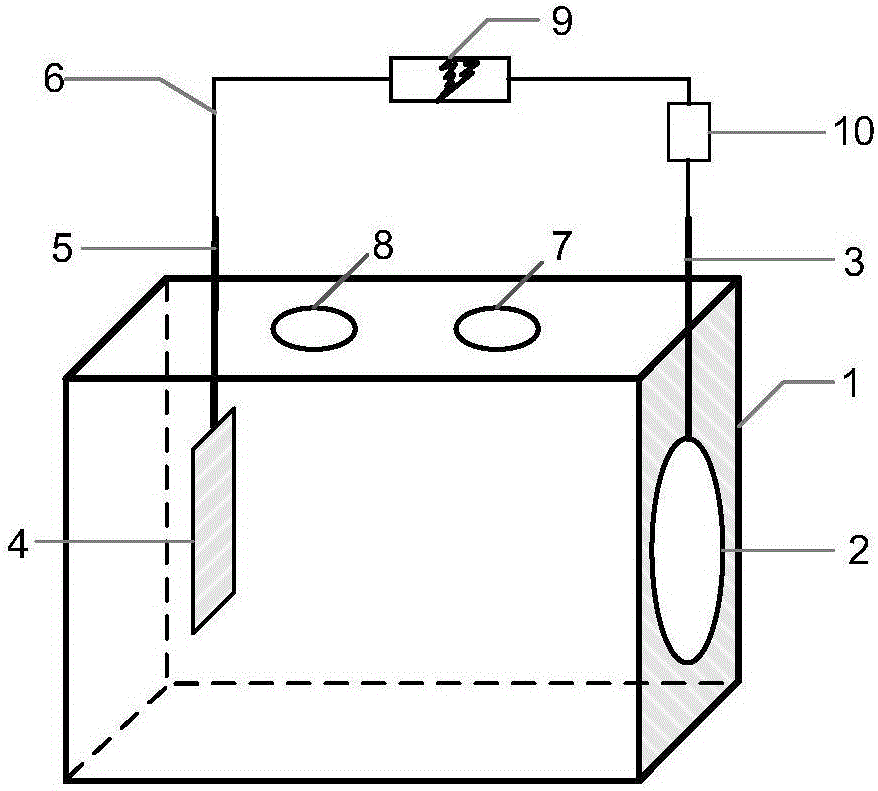

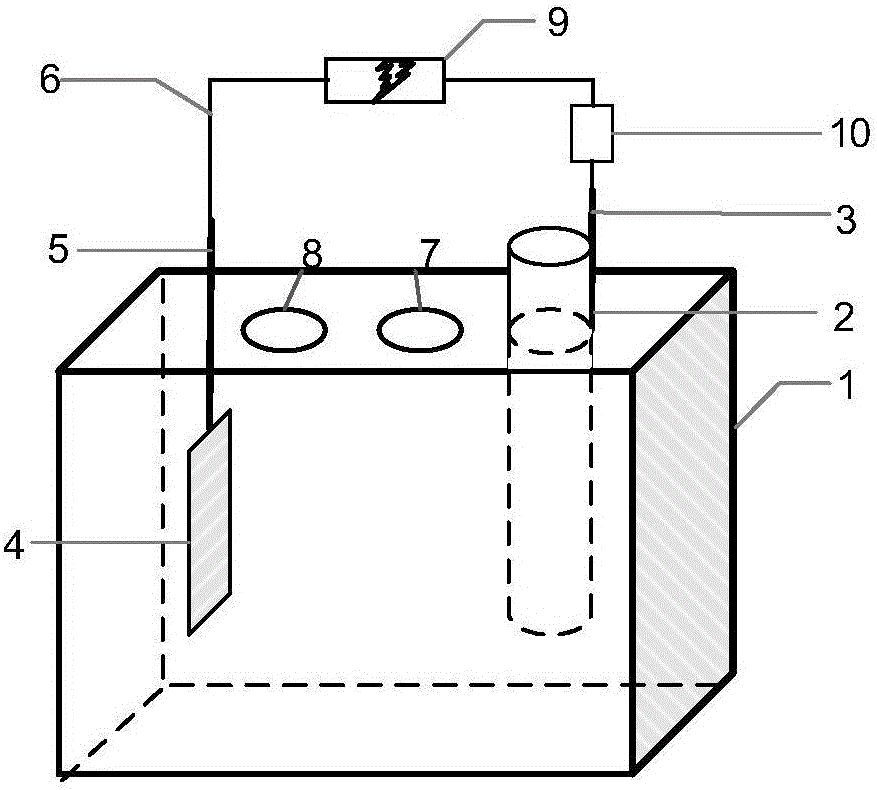

[0051] The groundwater has a pH of 7, a conductivity of 1500 μs / cm, and an As(III) content of 500 μg / L. The air cathode-electroflocculation reactor is powered by a DC stabilized power supply (the schematic diagram of the reactor is shown in figure 2 ), fixed voltage 1V. Take 1 mL of water sample every 10 minutes, and measure As(III) and total arsenic changes after passing through a 45 μm water filter membrane, as shown in Figure 5 , 6 shown. The energy consumption of the air cathode-electrocoagulation system can be calculated by P=UIt, wherein the current I is the real-time record of the automatic data acquisition system, and t is the time when the total arsenic reaches 10 μg / L, such as Figure 9 shown.

Embodiment 2

[0053] The groundwater has a pH of 7, a conductivity of 1500 μs / cm, and an As(III) content of 500 μg / L. The air cathode-electroflocculation reactor is powered by a DC stabilized power supply (the schematic diagram of the reactor is shown in figure 2 ), fixed voltage 2V. Take 1 mL of water sample every 10 minutes, and measure As(III) and total arsenic changes after passing through a 45 μm water filter membrane, as shown in Figure 7 , 8 shown. The energy consumption of the air cathode-electrocoagulation system can be calculated by P=UIt, wherein the current I is the real-time record of the automatic data acquisition system, and t is the time when the total arsenic reaches 10 μg / L, such as Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com