Method for simultaneously producing hydrogen peroxide and hydrogen through autonomous oxygen supply double-cathode device

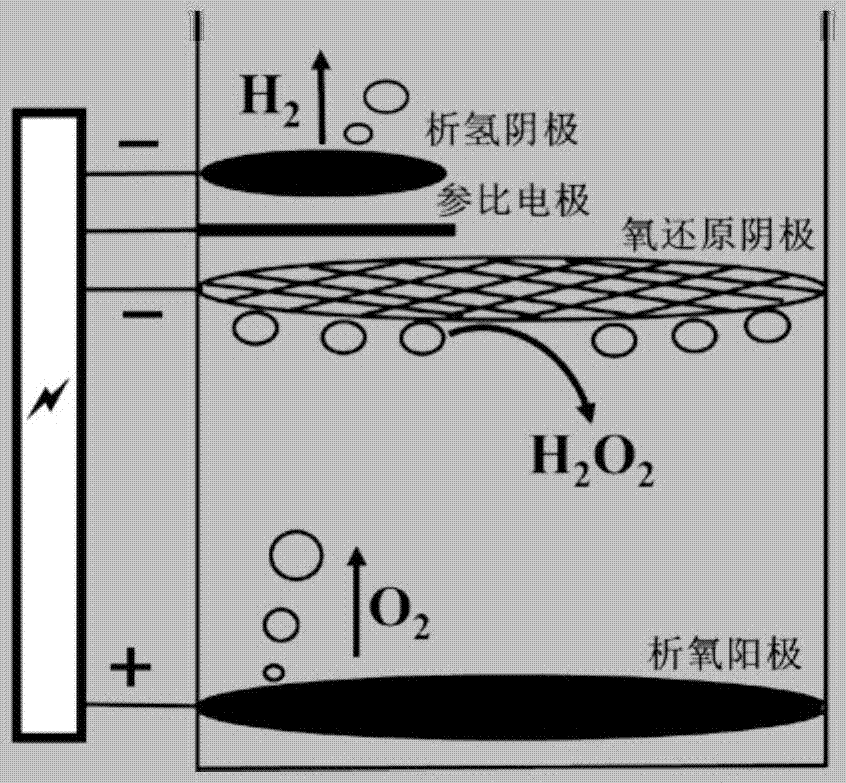

A dual-cathode, hydrogen peroxide technology, applied in the electrolysis process, electrolysis components, etc., can solve problems such as lack of oxygen, difficult work of the device, and air difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

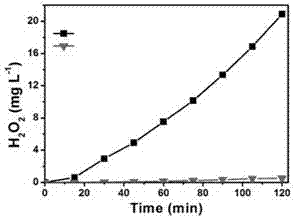

[0025] in neutral Na 2 SO 4 In the solution, a power supply is used to supply power to the self-supplying hydrogen peroxide generator, the hydrogen evolution cathode adopts a constant current mode, and the constant current is 5mA, and the oxygen reduction cathode adopts a constant voltage mode, and the constant voltage is 0.4V (relative to the Ag / AgCl reference electrode, after Conversion, -0.21V relative to the standard hydrogen electrode potential), the oxygen evolution anode is used as a common counter electrode. Take 1mL of samples every 15min, then inject 1mL of electrolyte solution, and use the titanium potassium oxalate method to measure H 2 o 2 Solubility, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com