A 3D printing device for semiconductor deep cooling and heating

A deep cooling, 3D printing technology, applied in the processing of heating elements, additive processing, etc., can solve the problems of the target object not reaching the precise size, deformed size, deviation, etc., to extend the contact area of cold and heat conduction, temperature reduction, cooling The effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

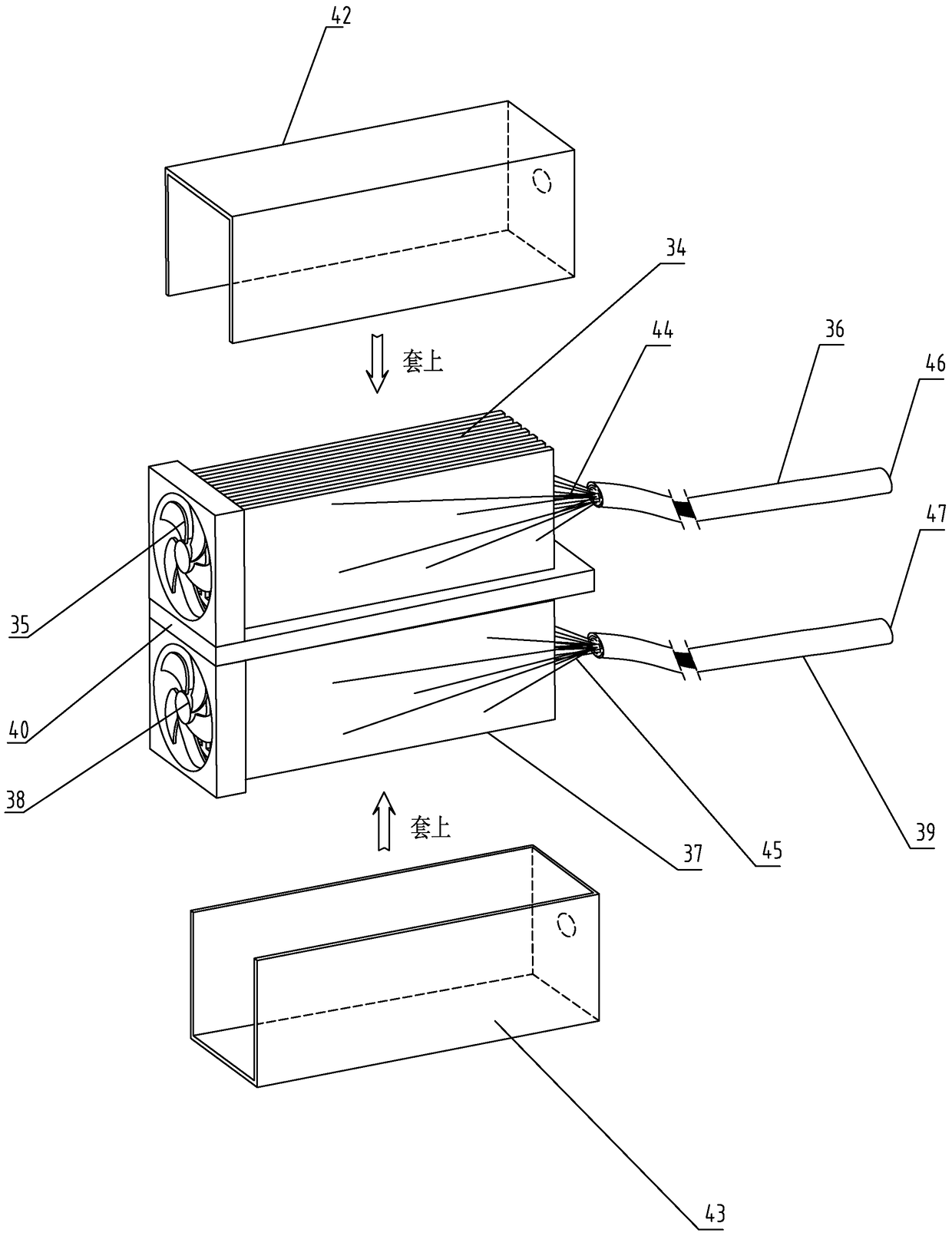

[0021] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

[0022] A 3D printing device for semiconductor deep cooling and heating, comprising: a cooling blast end and a heating blast end.

[0023] Metal cooling grids 34, blowing cooling fans 35, cold guiding air ducts 36, cold insulation casings 42, and cooling metal wires 44 are arranged at the cooling end of the semiconductor cooling sheet 40 to form the cooling blast end together, specifically: metal cooling grids Sheet 34 is made up of multi-layer metal sheets with high heat conductivity, and is close to the cooling end of semiconductor cooling sheet 40. One end of the cooling wire 44 is fixed on its surface, and the rest of the cooling wire 44 is all attached to the cooling air. On the inner wall of the pipe 36, the cold-guiding air pipe 36 is connected to the cold-insulation casing 42, and the blowing cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com