A drill rod displacement trigger mechanism for a breaking hammer

A technology of triggering mechanism and breaking hammer, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, road, etc., can solve the problems such as the inability to release the kinetic energy of beating, the damage of the drill rod, and the increase of equipment operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

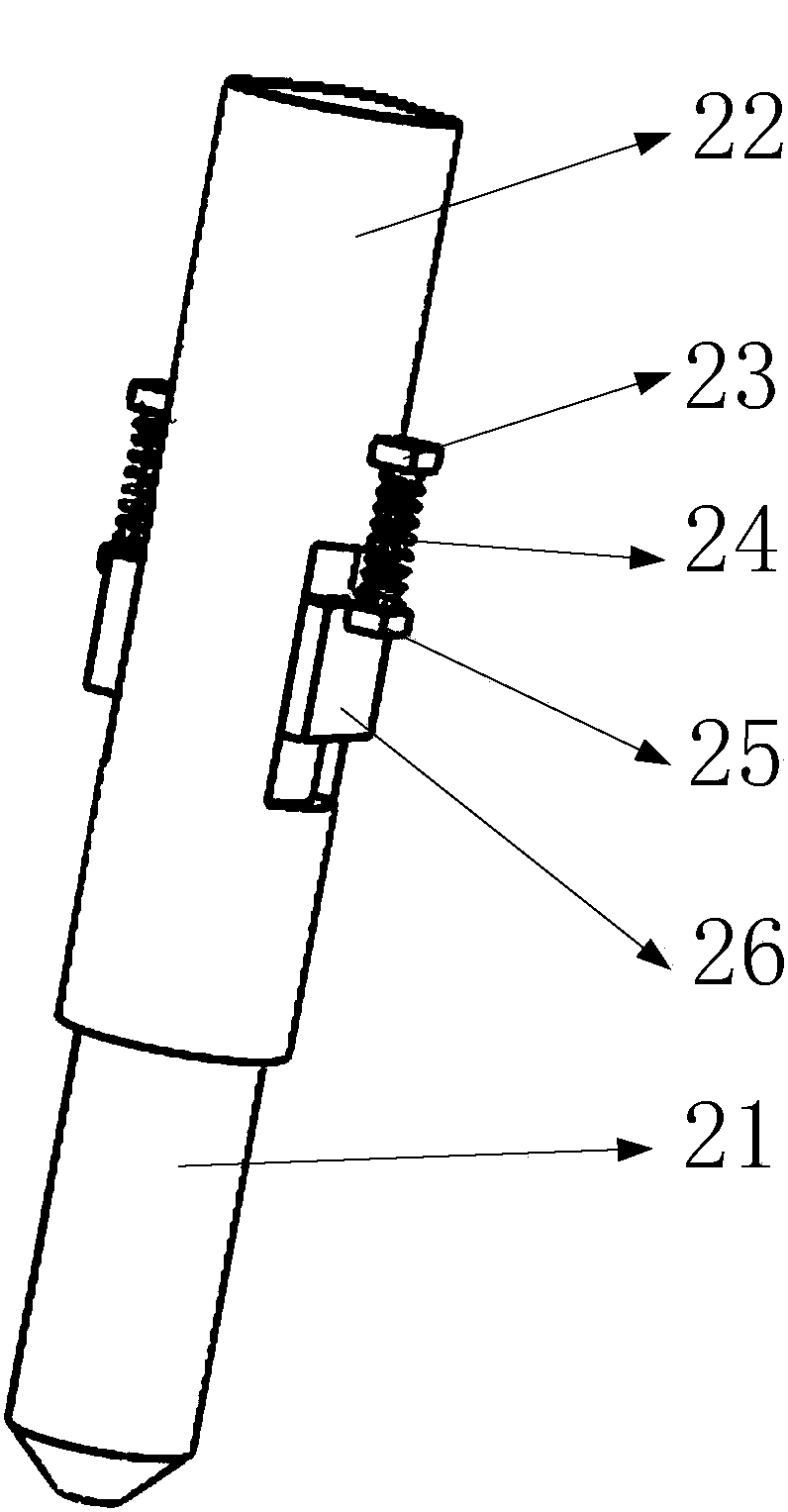

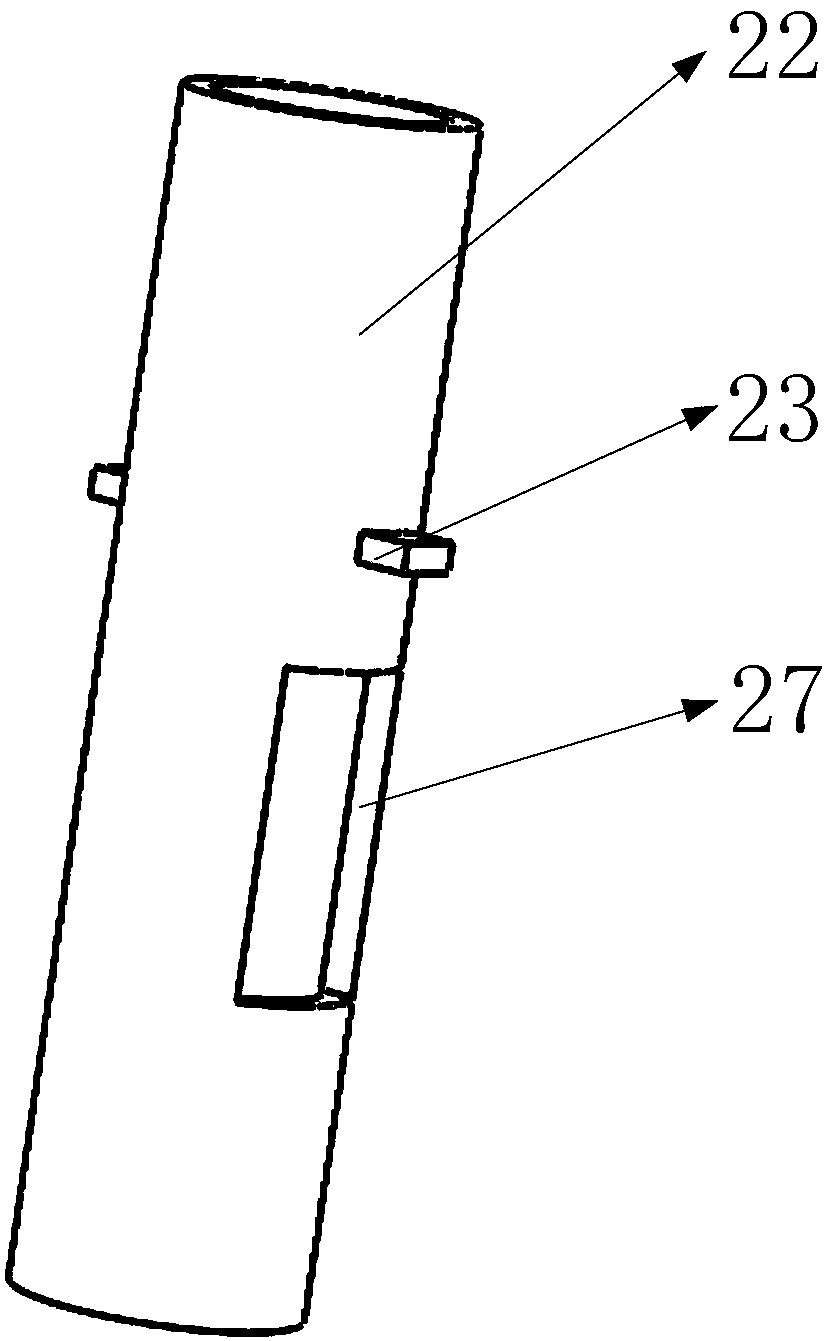

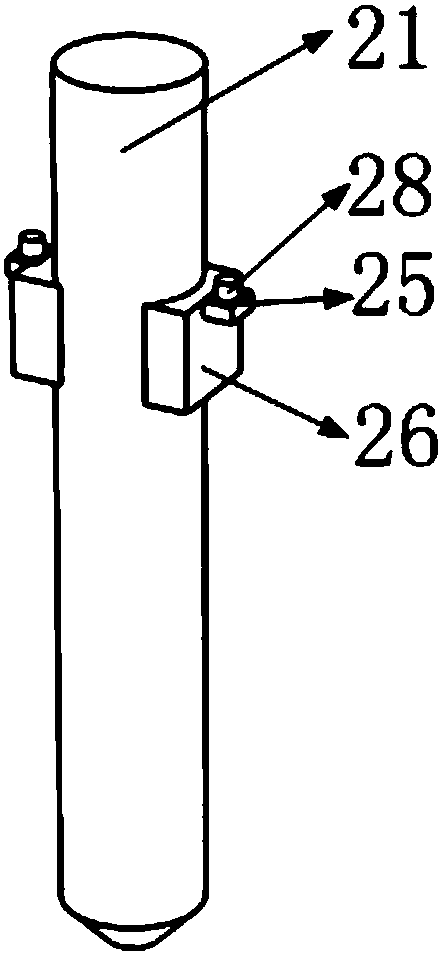

[0021] Such as Figure 4 As shown, it includes driving slider, limit block, guide rail, first support plate, amplitude valve body, first valve block, hydraulic hole, second valve block, third valve block, fourth valve block, second support plate, drive chute, valve body chute, valve body shell, third support plate, valve body spring, drill rod, drill rod sleeve, first drill rod spring support, drill rod spring, second drill rod spring support, drill rod Rod guide block, drill rod sleeve sliding hole, spring pin, such as figure 2 As shown, there is a drill rod sleeve sliding hole in the lower part of the drill rod sleeve and runs through the entire drill rod sleeve. The two first drill rod spring supports are symmetrically installed on the drill rod sleeve and are located on the upper side of the drill rod sleeve slide hole. ,Such as image 3 As shown, two drill rod guide blocks are installed symmetrically in the middle of the drill rod, and a second drill rod spring support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com