A rope-drawn gravity breaker

A breaking hammer and gravity technology, applied in the direction of grain processing, etc., can solve the problems that affect the development of the breaking hammer and the low effect of the breaking hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

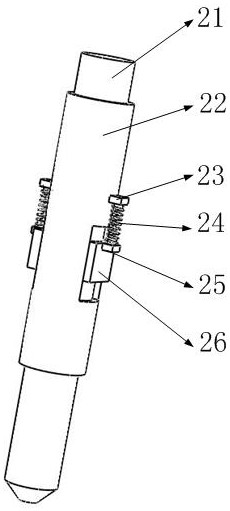

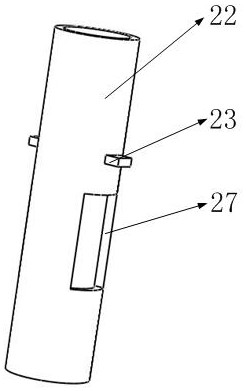

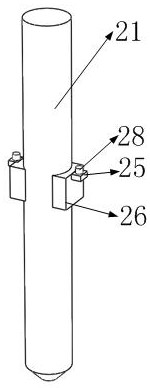

[0028] Such as Figure 7 , 8 , 9, it includes hydraulic motor 1, second pulley 2, motor shaft 3, first wire wheel 4, clutch ring 5, second wire wheel 6, impact block 7, impact block pull ring 8, first steel wire 9 , the second steel wire 10, the impact block guide groove 11, the impact block guide rail 12, the impact block spring fixed column 13, the impact block spring 14, the guide rail support 15, the drill rod 21, the drill rod sleeve 22, the first drill rod spring support 23, Drill rod spring 24, second drill rod spring support 25, drill rod guide block 26, drill rod sleeve sliding hole 27, spring pin 28, first outer plate 30, first pulley 31, gravity chamber 32, second outer plate 33 , side plate reinforcing rib 34, steel wire fixing structure 36, gravity block 37, first pulley fixing plate 40, wherein as Figure 8 As shown, the hydraulic motor 1 is installed on the upper side of the second outer plate 33; the second wire wheel 6 and the first wire wheel 4 are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com