An integral striking gravity breaking hammer

A breaking hammer and gravity technology, applied in the direction of grain processing, etc., can solve the problems of low breaking hammer effect and affecting the development of breaking hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

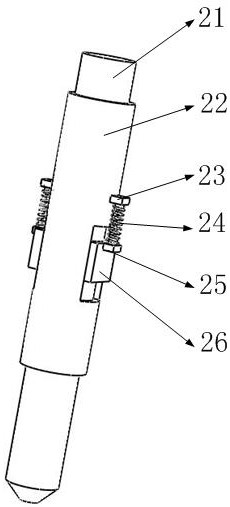

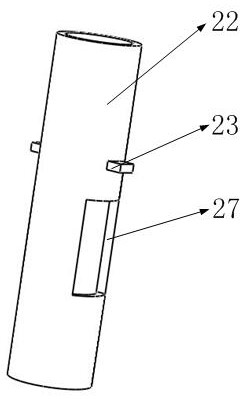

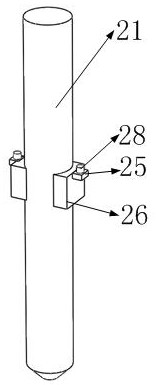

[0027] like Image 6 , 8 As shown, it includes hydraulic brake 1, hydraulic motor 2, gravity chamber guide groove 3, gravity chamber guide rail 4, first gravity chamber spring support 5, gravity chamber spring 6, second gravity chamber spring support 7, hydraulic motor shaft support 8 , brake support 9, second pulley 10, first pulley 11, wire wheel 12, drill rod 21, drill rod sleeve 22, first drill rod spring support 23, drill rod spring 24, second drill rod spring support 25, drill rod Rod guide block 26, drill rod sleeve sliding hole 27, spring pin 28, first outer plate 30, first pulley 31, gravity cavity 32, second outer plate 33, side plate reinforcement rib 34, steel wire fixing structure 36, gravity block 37. The first pulley fixing plate 40, wherein as Figure 7 As shown, the above-mentioned first outer panel 30 is fixed to the second outer panel 33 through a plurality of side panel reinforcing ribs 34; Figure 10 , 11 As shown, gravity chamber guide rails 4 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com