Accelerated testing method of reliability of ball screw pair

A ball screw pair, accelerated test technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of long reliability test time, insufficient test sample size, high cost, and achieve high test cost and simple and easy methods. The effect of improving the test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

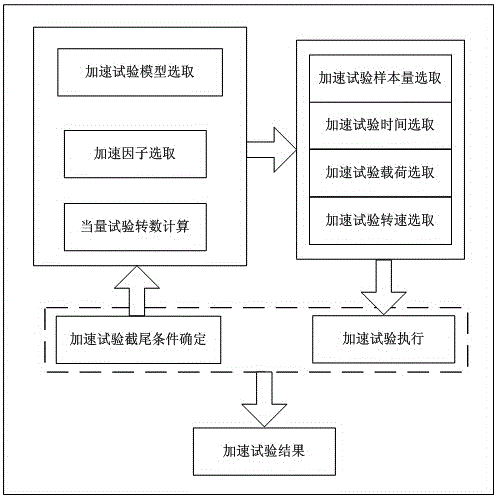

[0033] Ball screw reliability accelerated test methods include the following:

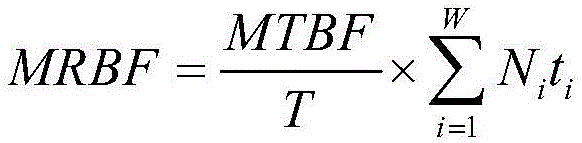

[0034] 1. Determine the MRBF of the ball screw pair:

[0035] Table 1 Time taken by a certain blade factory to process typical blade parts

[0036] Speed (RPM)

time (min)

100

25

200

5

400

3

0 (Loading and loading and intermittent time)

90

[0037] Calculated according to the MTBF of the CNC machine tool = 4000 hours, the number of revolutions of the corresponding ball screw pair is at least:

[0038]

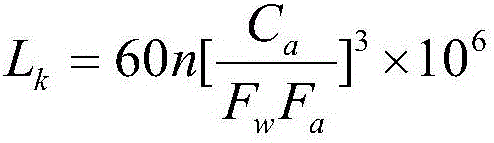

[0039] Table 1 shows the time taken by a certain blade factory to process typical blade parts. Through the case analysis of typical workpieces processed by the above machining centers, it can be known that: when the MTBF of the CNC machine tool is 4000 hours, the corresponding number of revolutions of the screw is 9.17 million revolutions. For the ball screw reliability testing test, the screw needs to be run-in on the ball screw reliabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com