Display screen, terminal and display screen making method

A production method and a technology of a display screen, which are applied in the field of display screens, can solve problems such as lack of integration, inconsistency, and influence on the visual effect of the display panel, and achieve the effect of enhancing the visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

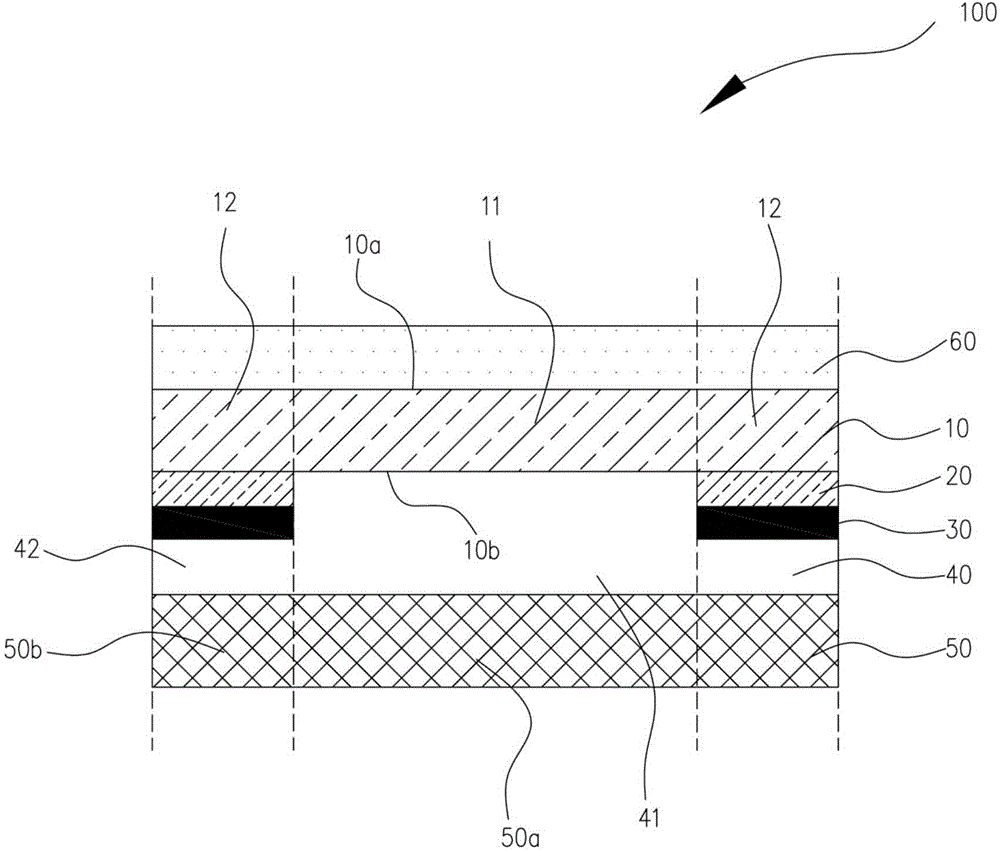

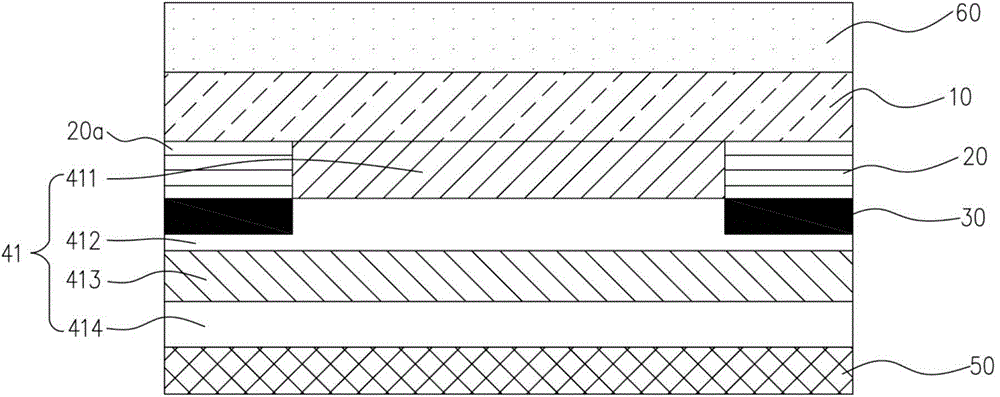

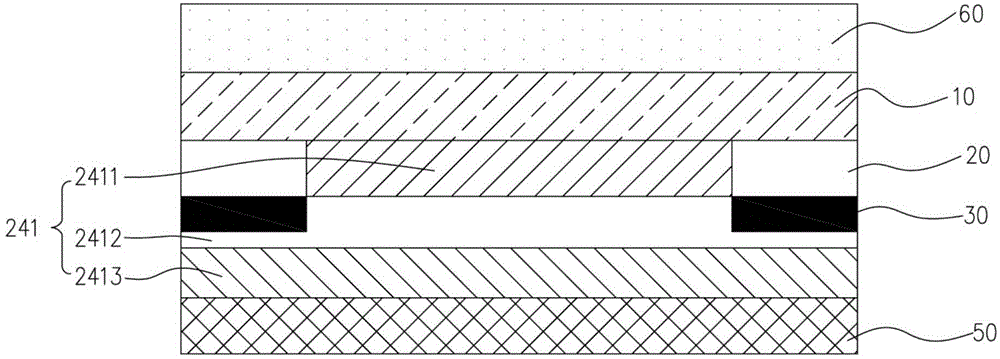

[0038] see figure 1 and figure 2 , a display screen 100 provided by the present invention, the display screen 100 includes a transparent protective plate 10, a reflective film 20, an ink layer 30, a functional layer 40 and a display layer 50 stacked in sequence, and the transparent protective plate 10 has a visible window 11 and a non-visible window 12, the non-visible window 12 surrounds the visible window 11, the reflective film 20 and the ink layer 30 are sequentially covered on the non-visible window 12, the functional layer 40 and the The display layer 50 sequentially covers the non-visible window 12 and the visible window 11 . The functional layer 40 can be an optical glue, used to attach the display layer 50 to the transparent protective plate 10; it can also be a to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com