A kind of manufacturing method of vdmos device and vdmos device

A manufacturing method and device technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low cell integration, and achieve the goal of simplifying the manufacturing process, reducing the manufacturing cost, and improving the cell integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

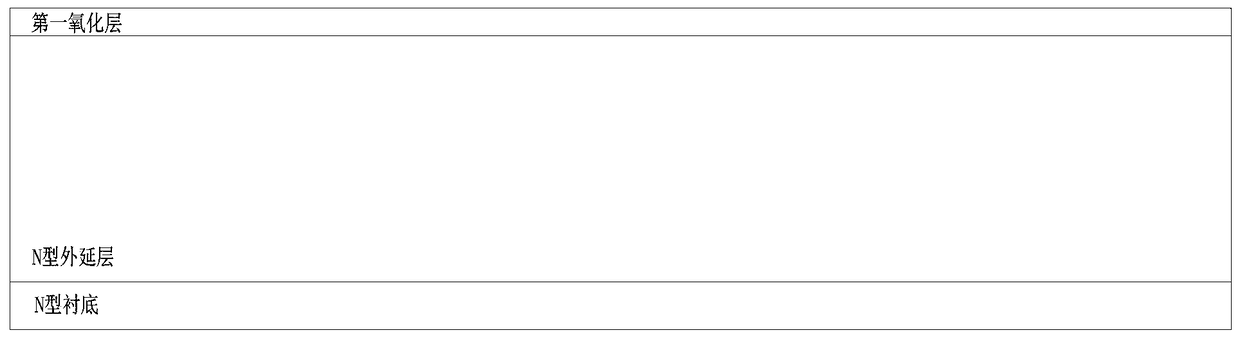

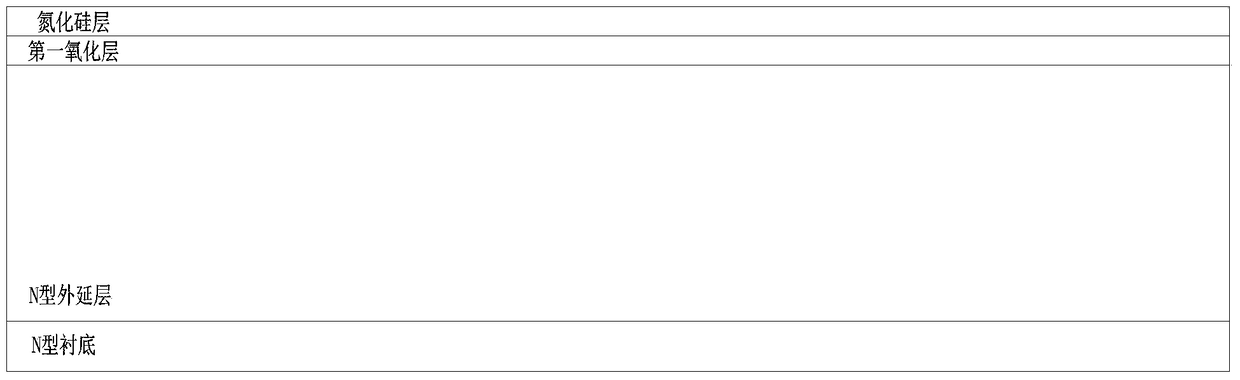

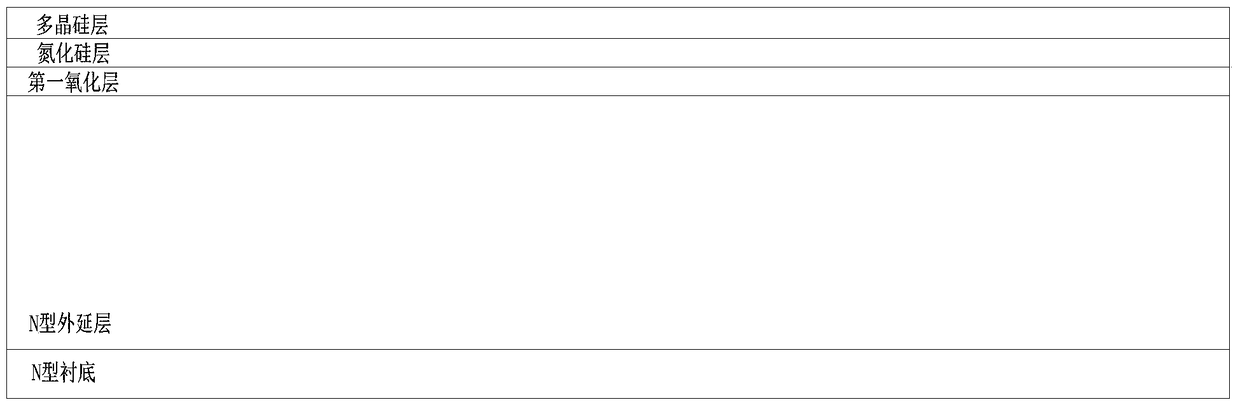

[0054] The present invention aims at the problem in the prior art that the manufacturing process of VDMOS devices involves the photolithography of contact holes, resulting in low cell integration, and provides a method for manufacturing VDMOS devices, such as Figure 1 to Figure 10 shown, including:

[0055] sequentially forming a first oxide layer and a silicon nitride layer on the first conductivity type epitaxial layer located on the first surface of the first conductivity type substrate;

[0056] forming a polysilicon gate on the silicon nitride layer;

[0057] forming a body region of a second conductivity type of a first concentration in the epitaxial layer of the first conductivity type, and the body region of the second conductivity type of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com