Filling roof connecting method used for upward drift ultrahigh undersampling

An ultra-high and under-mining, access technology, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of unsatisfactory filling effect, inability to connect to the top, and achieve good application prospects and social value. , good filling strength, the effect of overcoming unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] A method and a filling process for superelevation under-mining filling and roofing of an upward approach, including the following steps:

[0021] 1. Preparation

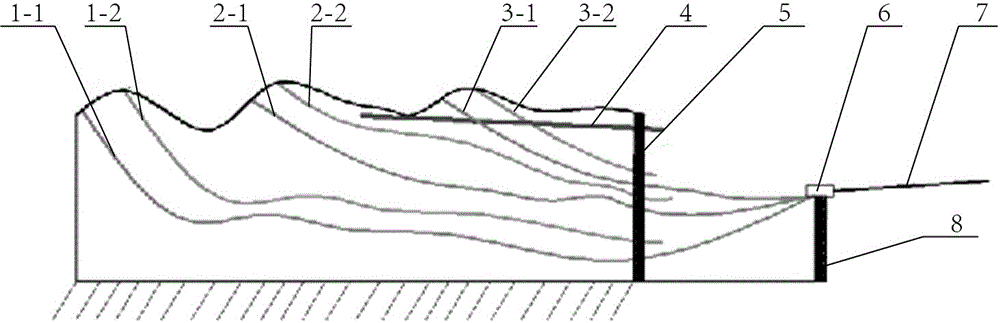

[0022] (1) A detachable composite panel wall 5 is installed at the outer mouth of the goaf. The detachable composite panel wall 5 uses geotextiles for water filtration, and a second panel wall 8 is installed on the outside of the detachable composite panel wall 5 and is covered with geotextiles. For secondary water filtration, the distance between the detachable composite board wall 5 and the second board wall 8 is 5m-10m. Such as figure 1 shown.

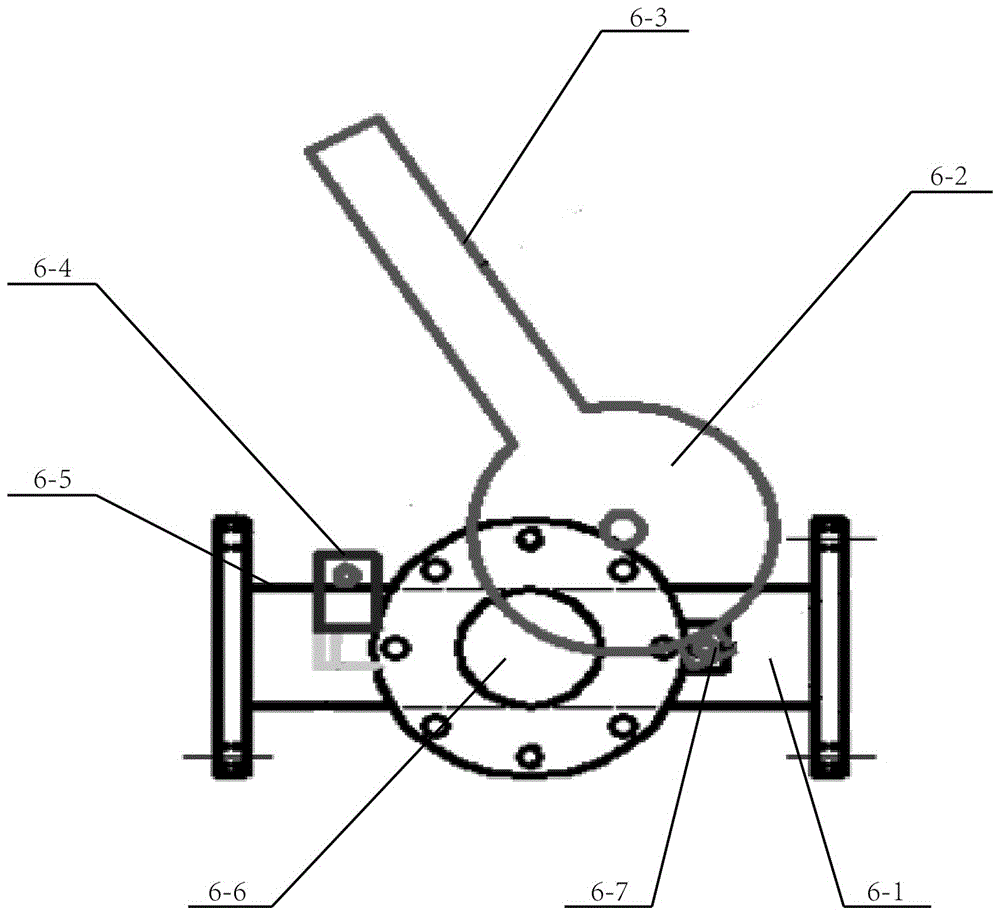

[0023] (2), install the water discharge tee 6 on the cross brace of the second board wall at the junction of the filling main road 7 and the second board wall 8; figure 2 As shown, the water discharge tee 6 includes a main pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com