A method to improve the filling rate of ore body

A technology of roof connection rate and ore body, which is applied to filling materials, mining equipment, earth square drilling and mining, etc., can solve the problems of low filling rate and unsatisfactory filling effect, and achieve good water permeability, good application prospects and social benefits. Good value and filling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] A method for improving the filling rate of ore bodies, comprising the following steps:

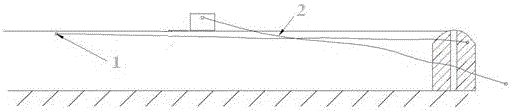

[0043] A. Arranging the stope: The stope is arranged in a "pin"-shaped structure. The upper layer of the "pin"-shaped stope is pressed down to the width of the layered approach to build a dam with a height of 0.5m. During the filling process, the upper layer is used to erect the veins The filling pipe 1 is used for filling, and the overflow water is easy to discharge.

[0044]B. Change the shape of the roof: the shape of the roof should be better suited to the needs of filling and roofing. The inclination angle of the roof and floor of the stope should be greater than the natural slope angle of the slurry to meet the needs of roofing. The roof should be set in an inclined shape and The inclination of the roof should be 8-15%. When the roof cannot be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com