Frame for transferring and storing composite insulators

A technology of composite insulators and shelves, which is applied in tool storage devices, workshop equipment, manufacturing tools, etc., can solve the problems of inconvenient counting of composite insulators, affecting the performance of composite insulators, and taking up a lot of space, so as to save storage space, Convenient storage and retrieval, increase storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present application is further described in conjunction with the following examples.

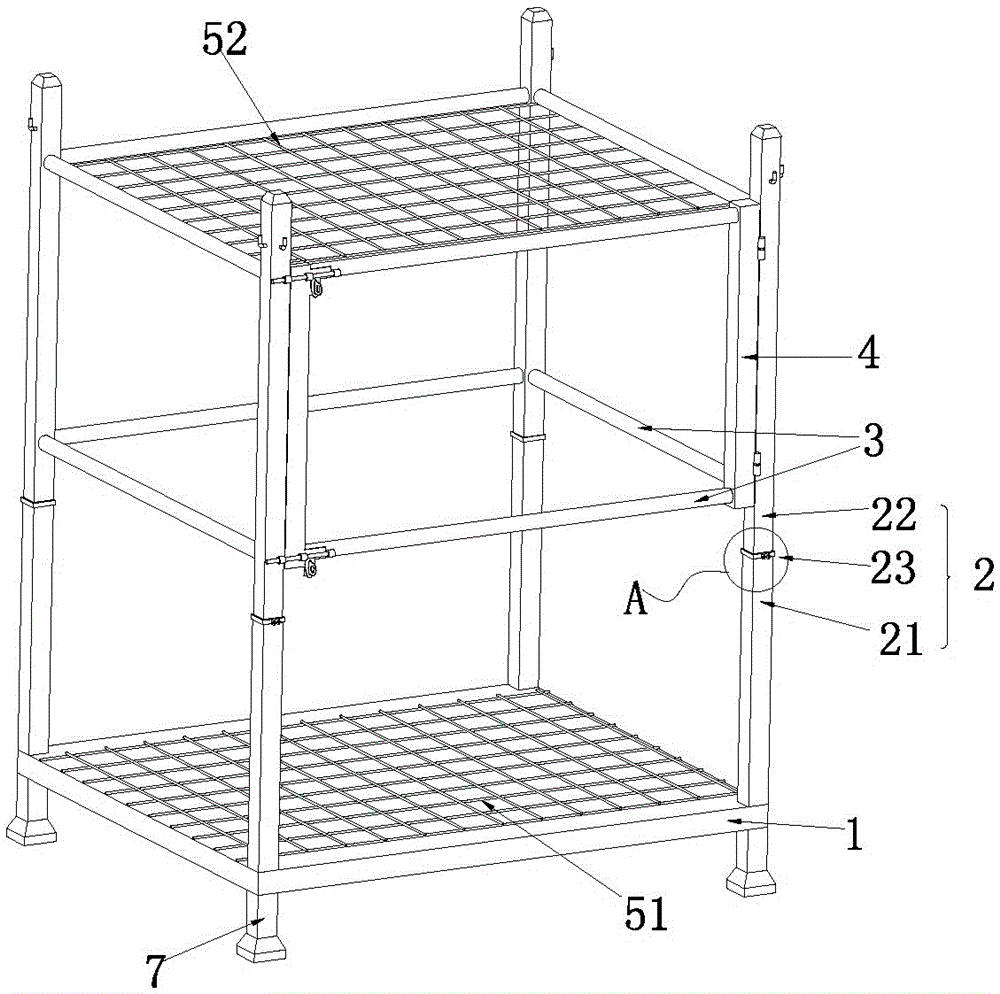

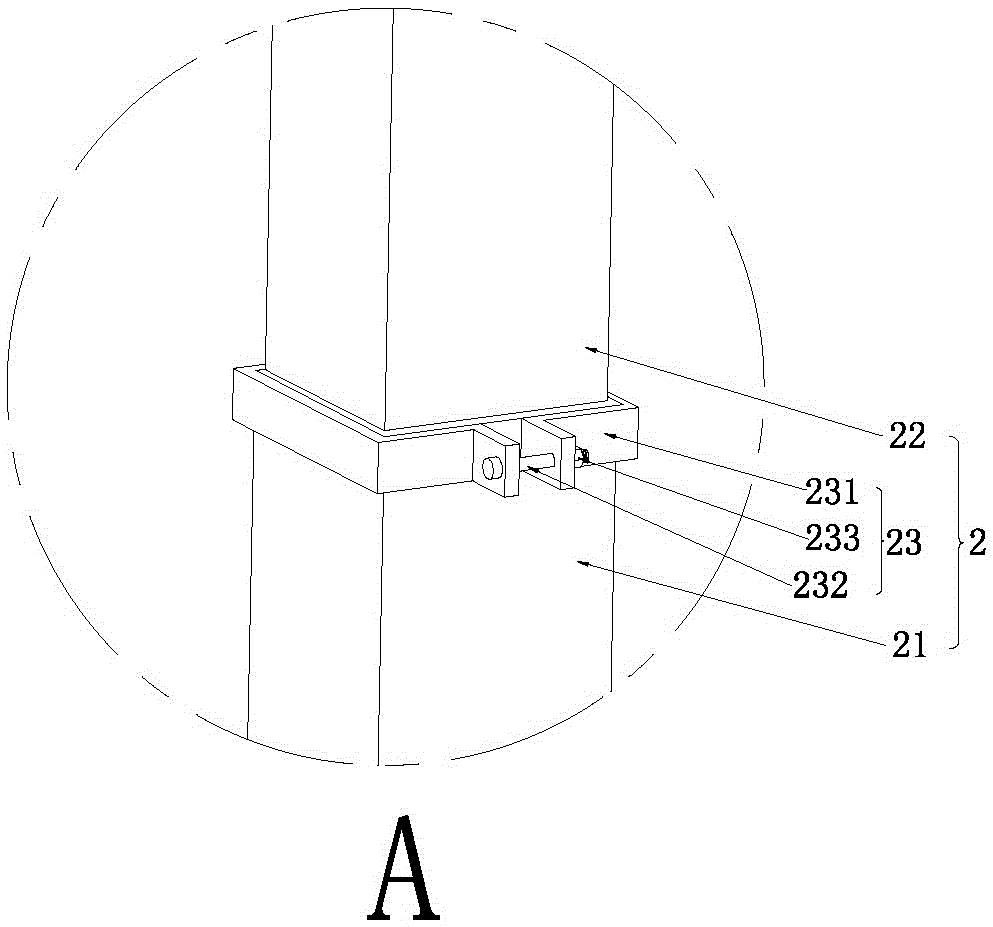

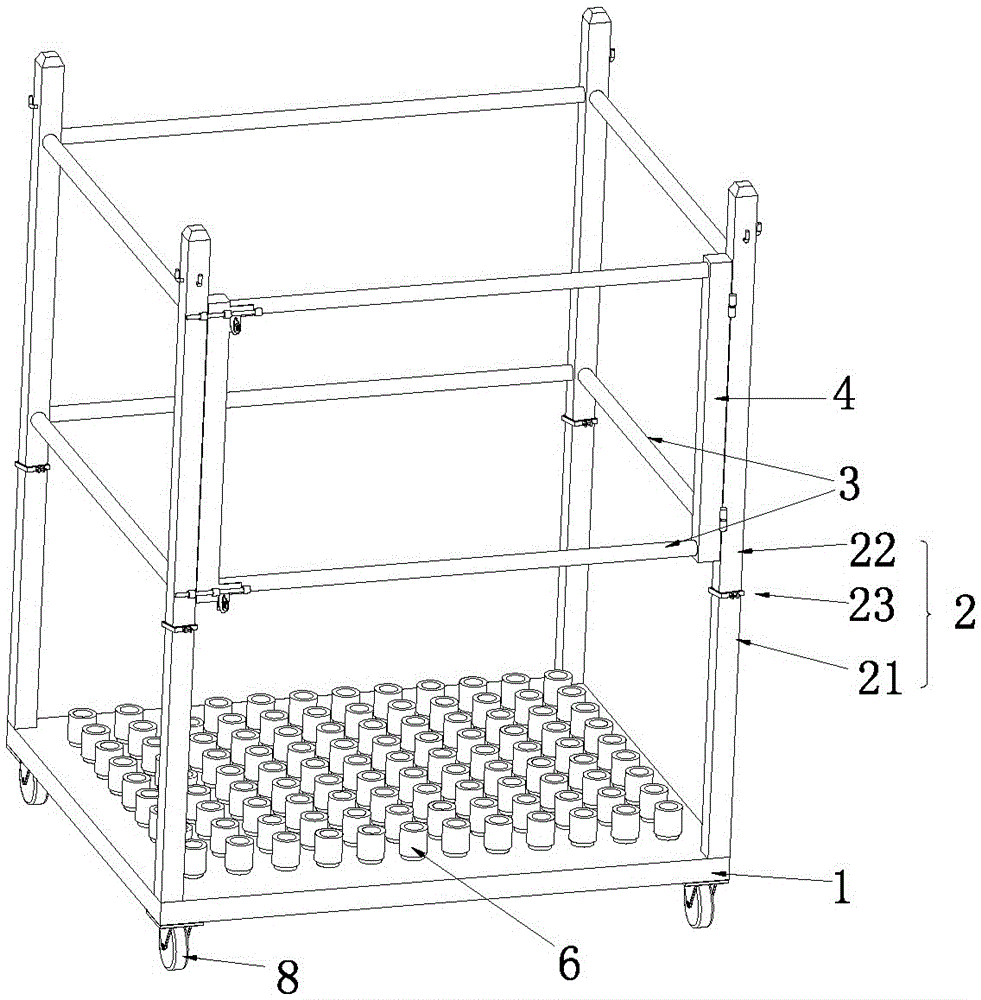

[0034] A specific embodiment of a shelf for transporting and storing composite insulators of the present application, such as Figure 1 to Figure 5 As shown, the bottom plate 1 is included. Specifically, the bottom plate 1 is in a square shape, and of course it can also be set in other shapes such as a circle or a triangle. Four columns 2 are vertically arranged on the square bottom plate 1, and the four columns 2 are respectively arranged on At the four corners of the bottom plate 1, cross beams 3 are arranged between adjacent columns 2 to increase the mechanical strength of the entire shelf, wherein, a movable door 4 can be arranged on either side of the shelf, and the movable door 4 passes through a hinge (folding) It is hinged with the column 2, and the storage and removal of the composite insulator is further facilitated by setting the movable door 4. In addition, the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com