Test method for adhesive strength of filter cartridge end cap

A test method and technology for adhesive force, which can be applied to measuring devices, instruments, and mechanical devices, etc., can solve the problem of not being able to intuitively reflect the adhesive force of the end cover of the filter cartridge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

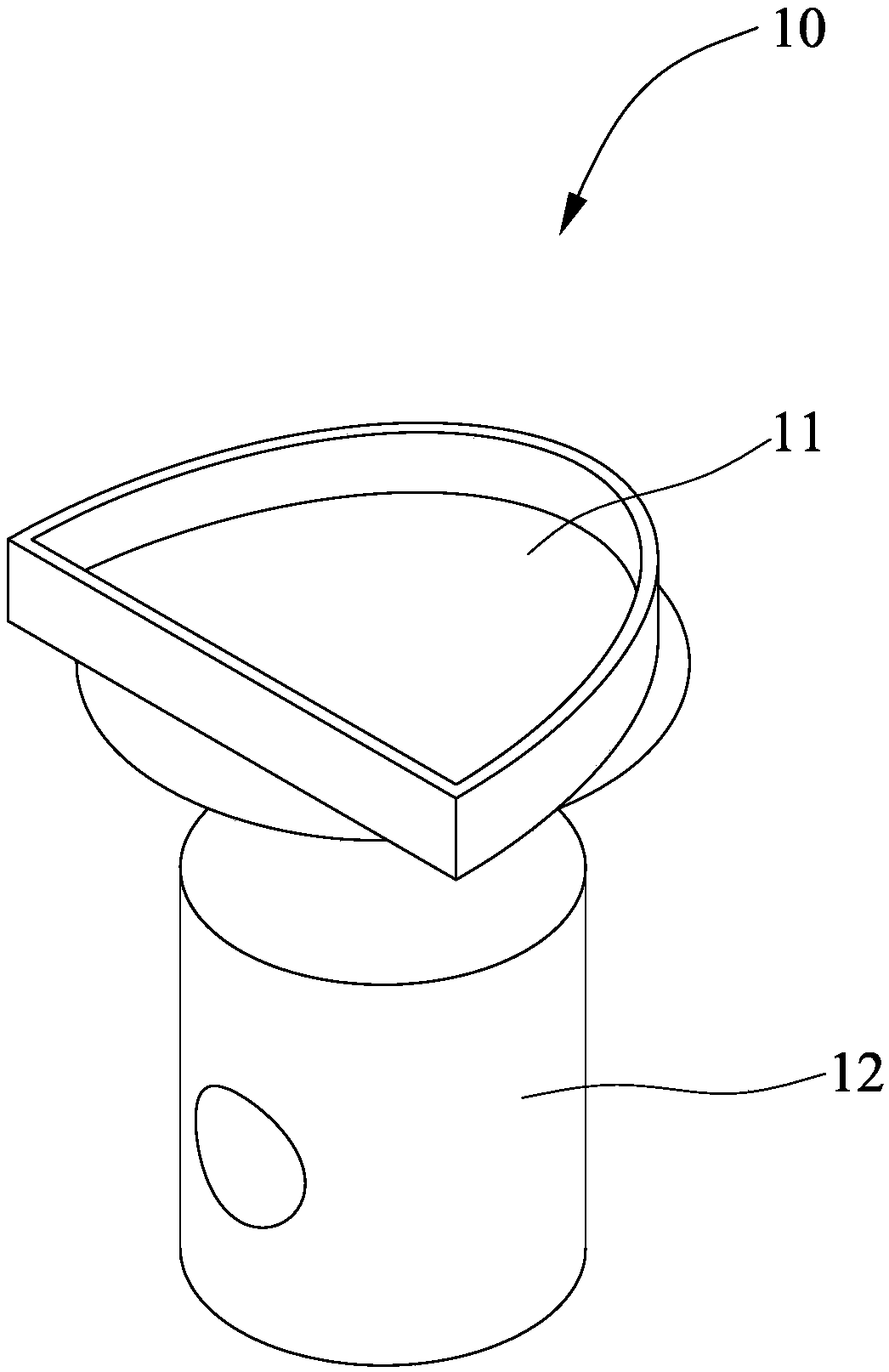

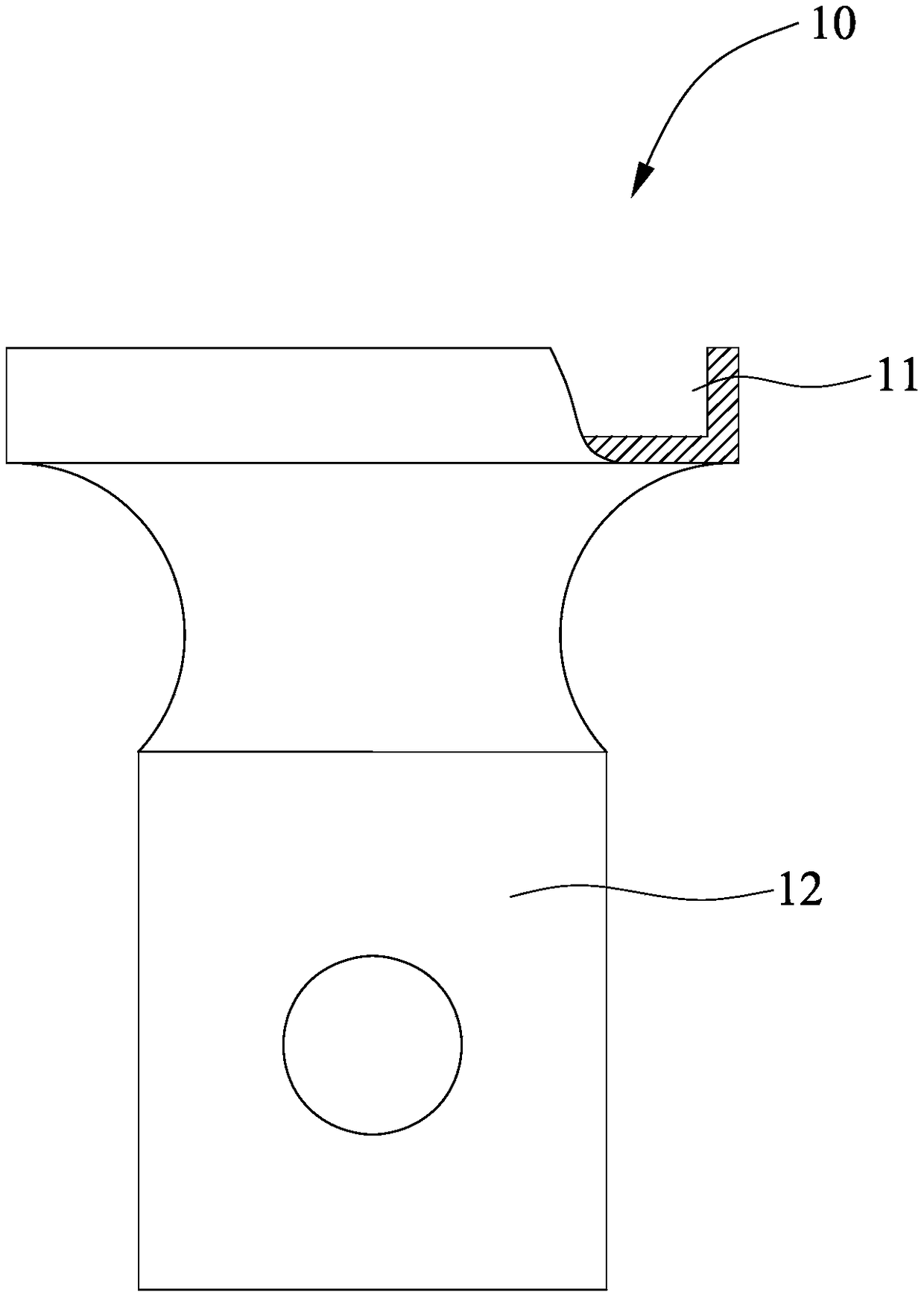

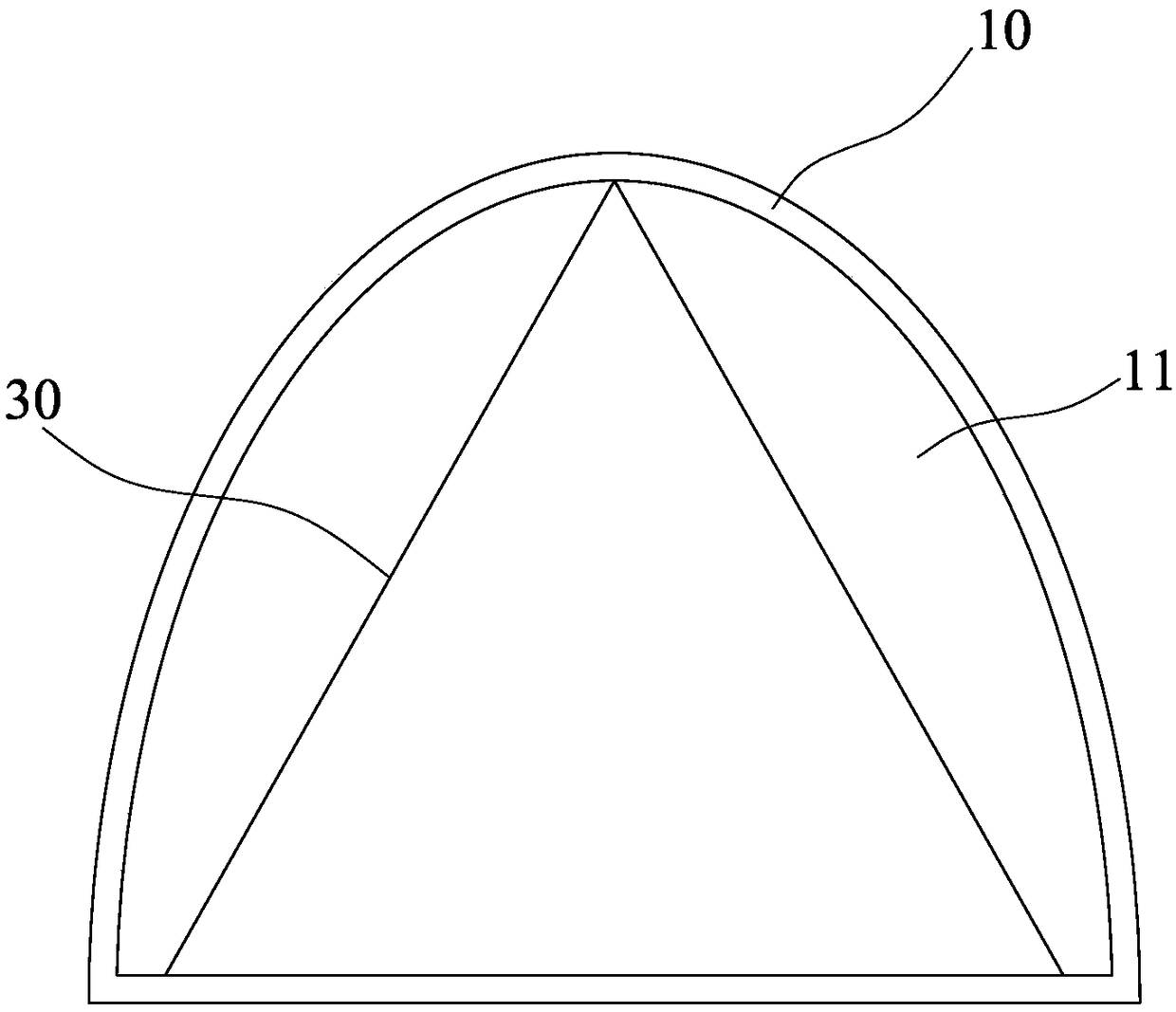

[0035] Pour the viscose 20A into the viscose groove 11 of the metal fixture 10. The thickness of the viscose is 5mm. Cut the cylinder body filter material 30 into a rectangle of 300mm*80mm, and fold it in half along the long side to form a "V" shape, that is, " The length of each side of the V" shape is 40mm, and the knuckle angle is 60°. Insert the filter material 30 "V" shape vertically into the viscose 20A that has been poured into the metal fixture 10 . After standing for 24 hours, the viscose 20A is completely cured. Fix the metal clamp 10 on the tensile strength machine with a bolt, clamp the filter material 30 with the clamp of the strength machine, test the tensile properties at a pulling speed of 100mm / min and record the fracture form. Repeat for 3 samples. The test structure of the 3 samples is recorded as follows:

[0036] Numbering

Embodiment 2

[0038] After mixing the two-component viscose 20B evenly in proportion, pour it into the viscose groove 11 of the metal fixture 10. The thickness of the viscose 20B is 5mm. Cut the cylinder body filter material 30 into a rectangle of 300mm*80mm, and align it along the long side Fold in half into a "V" shape, that is, the length of each side of the "V" shape is 40mm, and the folding angle is 60°. Insert the "V" shaped side of the filter material 30 vertically into the viscose 20 that has been poured into the metal fixture 10 . After standing for 8 hours, the viscose 20B is completely cured. Fix the metal clamp 10 on the tensile strength machine with a bolt, clamp the filter material 30 with the clamp of the strength machine, test the tensile properties at a pulling speed of 100mm / min and record the fracture form. Repeat for 3 samples. The test structure of the 3 samples is recorded as follows:

[0039] Numbering

Embodiment 3

[0041] Pour the viscose 20C into the viscose groove 11 of the metal fixture 10. The thickness of the viscose 20C is 7mm. Cut the cylinder body filter material 30 into a rectangle of 300mm*80mm, and fold it in half along the long side to form a "V" shape, that is The length of each side of the "V" shape is 40mm, and the folding angle is 60°. Insert the filter material 30 "V" shape vertically into the viscose 20C that has been poured into the metal jig 10 . After standing for 12 hours, the viscose 20C is completely cured. Fix the metal clamp 10 on the tensile strength machine with a bolt, clamp the filter material 30 with the clamp of the strength machine, test the tensile properties at a pulling speed of 100mm / min and record the fracture form. Repeat for 3 samples. The test structure of the 3 samples is recorded as follows:

[0042] Numbering

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com