A waterway pressure-resistant hydraulic control reversing valve

A hydraulically controlled reversing valve and pressure-resistant technology, applied in multi-way valves, valve devices, fluid pressure actuating devices, etc., can solve the problems of low working pressure and non-compliance with coal mine safety operation regulations, and achieve high-pressure sealing. Problems, the effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

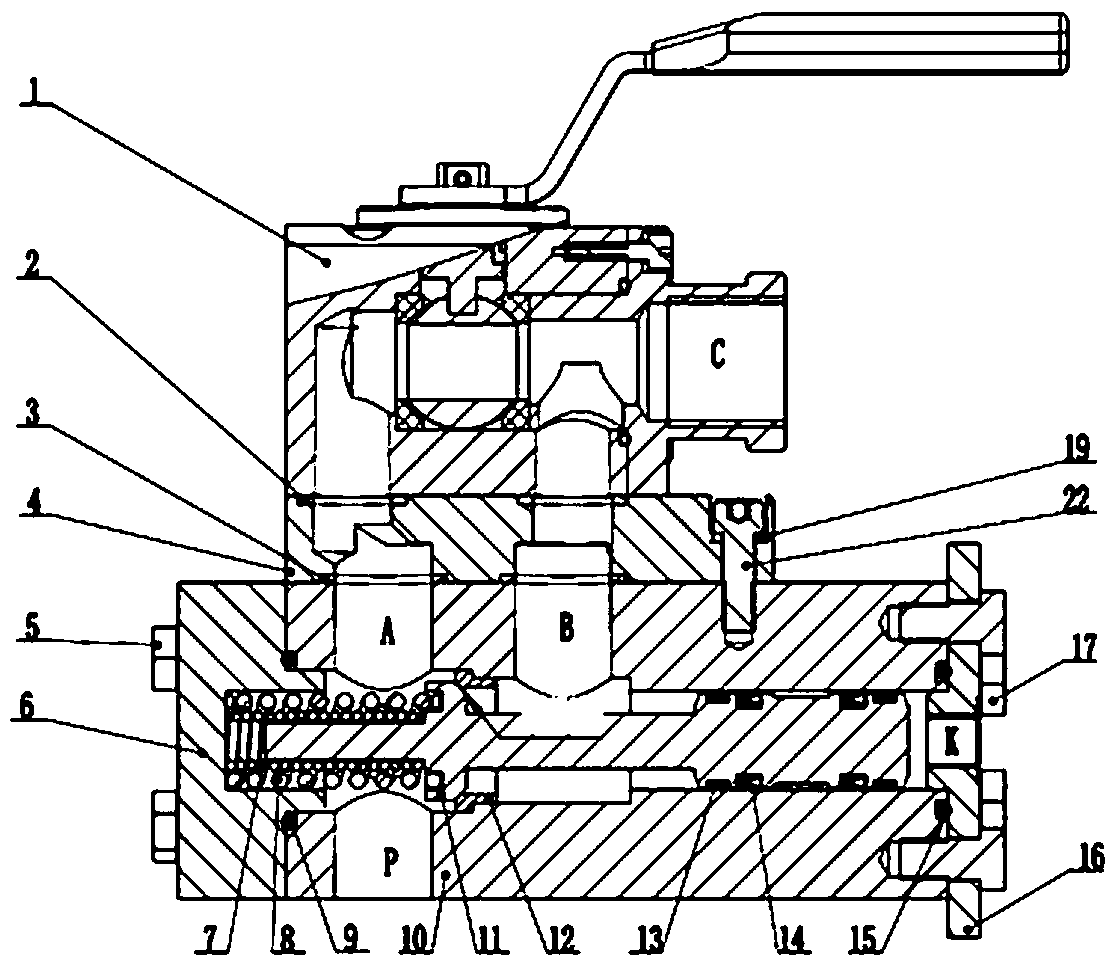

[0013] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0014] like figure 1 As shown, the waterway pressure-resistant hydraulic control reversing valve includes ball valve 1, combined gasket I2, combined gasket II3, middle plate 4, end cover fastening bolts 5, end cover 6, spring I7, spring II8, end cover O type Ring 9, valve body 10, valve core 11, sealing sleeve 12, guide belt 13, sealing ring 14, bottom cover O-ring 15, bottom cover 16, bottom cover fastening bolt 17, washer and ball valve fixing bolt 19. Its working pressure is relatively high, its sealing performance is good, and it has two switch modes of manual and hydraulic control.

[0015] Specifically, the waterway pressure-resistant hydraulic control reversing valve is divided into an upper valve and a lower valve, which are connected as a whole. The upper valve is a ball valve 1, and the upper valve has valve ports I and III located on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com