Self-sticking type waterproof board, drainage board and waterproofing and drainage board

A waterproof and drainage board technology, applied in drainage, shaft lining, tunnel lining, etc., can solve problems such as low construction efficiency, difficulty in ensuring the quality of tunnel waterproof and drainage, leakage of waterproof boards, drainage boards or waterproof and drainage boards, etc. Achieve the effects of improving construction efficiency, ensuring the quality of waterproof and drainage construction, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

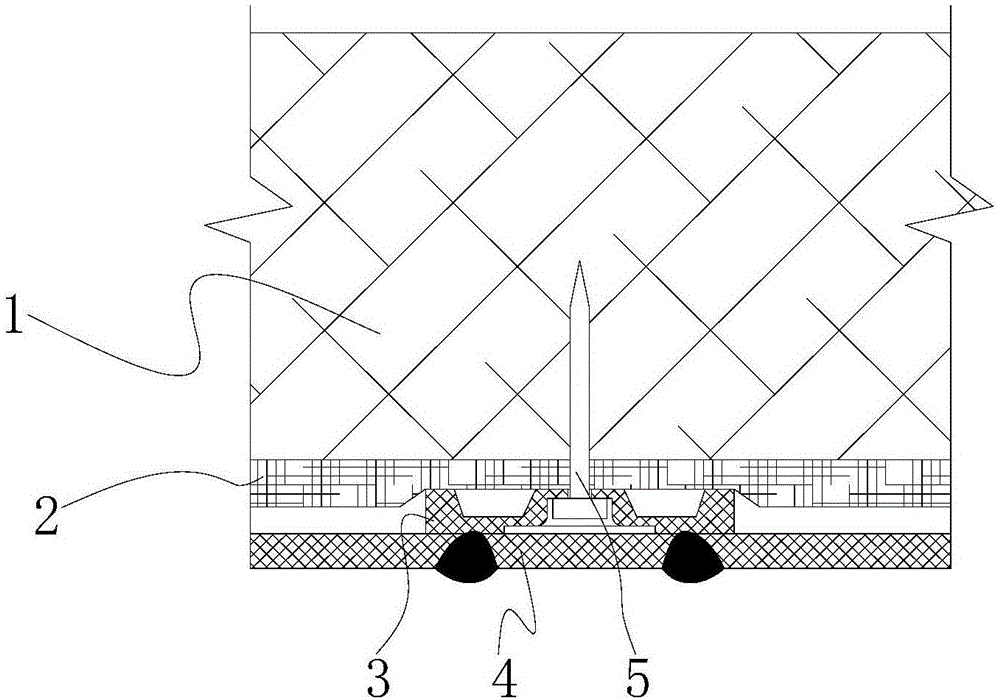

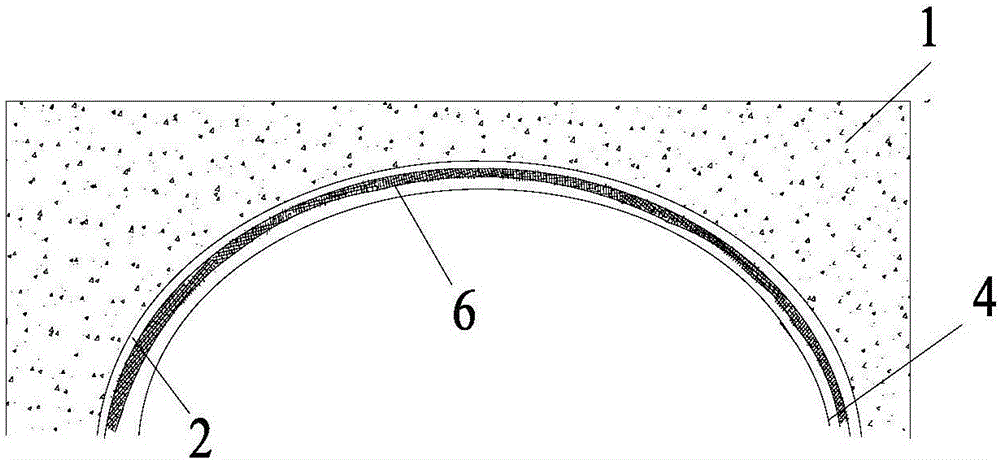

[0026] see figure 2 , The installation method of the self-adhesive waterproof and drainage board is as follows: a buffer layer 2 is laid on the initial support of the tunnel 1, the buffer layer is made of geotextile, and the waterproof and drainage board 4 is fixed on the geotextile through a hook and loop 6.

[0027] see image 3 and Figure 5 , the self-adhesive waterproof and drainage board is a prefabricated part made of PE material. A Velcro is arranged every 1 meter, the length of the Velcro is 30cm, and the width is 10cm.

Embodiment 2

[0029] The installation method of the self-adhesive waterproof board is as follows: lay a geotextile on the initial support 1 of the tunnel, hang the self-adhesive waterproof board on the surface of the geotextile, and fix it on the geotextile through the hook and loop 6 .

[0030] The self-adhesive waterproof board is a prefabricated board made of EVA. The main body of the waterproof board is a plane light board of equal thickness, and one side of the waterproof board is compounded with a self-adhesive layer. The self-adhesive layer is a nylon hook strip with a width of 5 cm, and the hook-free side of the hook strip is laminated on the waterproof board with hot melt adhesive. The width of the waterproof board is 4m, and a hook surface is compounded every 1 meter. The length of each hook surface is the same as the length of the waterproof board body. The geotextile is made of polyester (polyethylene terephthalate, PET).

Embodiment 3

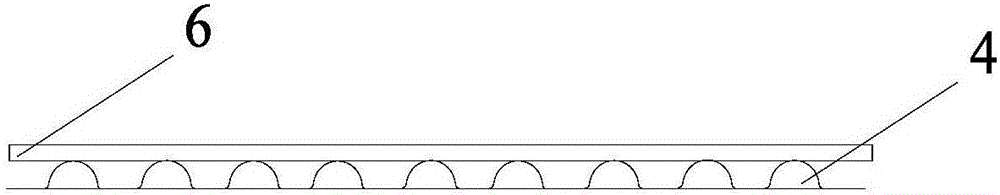

[0032] see figure 2 and image 3 , the installation method of the convex-hull type waterproof and drainage board is as follows: a geotextile is laid on the initial support of the tunnel 1, and the outer surface of the geotextile is laid with a convex-hull type waterproof and drainage board, which is bonded to the geotextile through the hook and loop 6.

[0033] Convex shell waterproof and drainage board is a prefabricated board. The hook surface with hookless side is thermally welded on the raised side of convex shell waterproof and drainage board. Velcro belt with a width of 20cm, and the length of the Velcro strip is the same as that of the main body of the convex shell type waterproof drainage board ( Figure 4 ).

[0034] The convex shell waterproof and drainage board is fixed on the geotextile through the hook and loop 6. The material of the geotextile is polypropylene and the specification is 400g / m 2 , the thickness is 3.5 ~ 4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com