image forming device

An image and paper technology, applied in the field of image forming devices, can solve problems such as image scale changes, paper jams, and complicated roller drive control, and achieve the effect of preventing speed changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

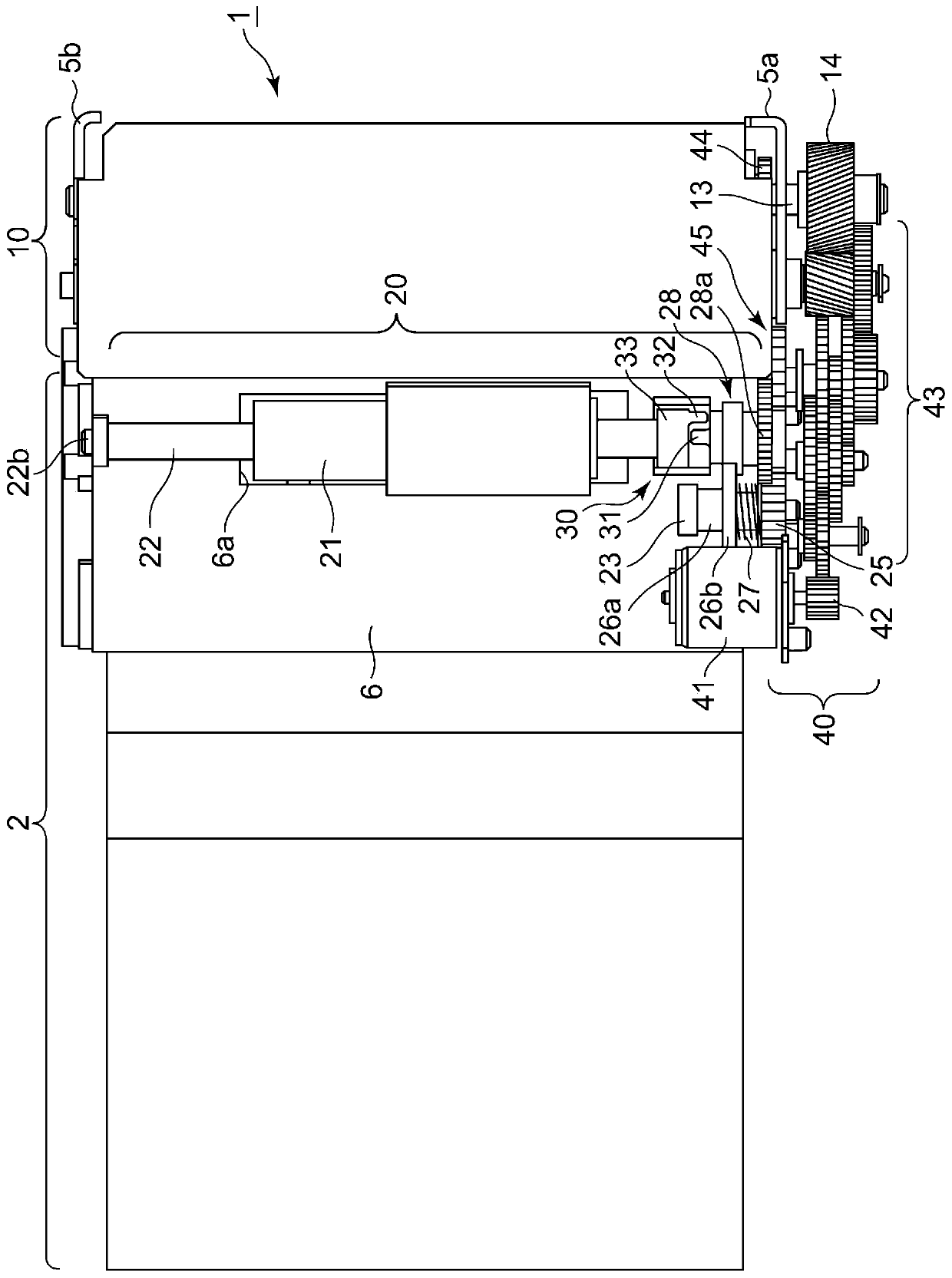

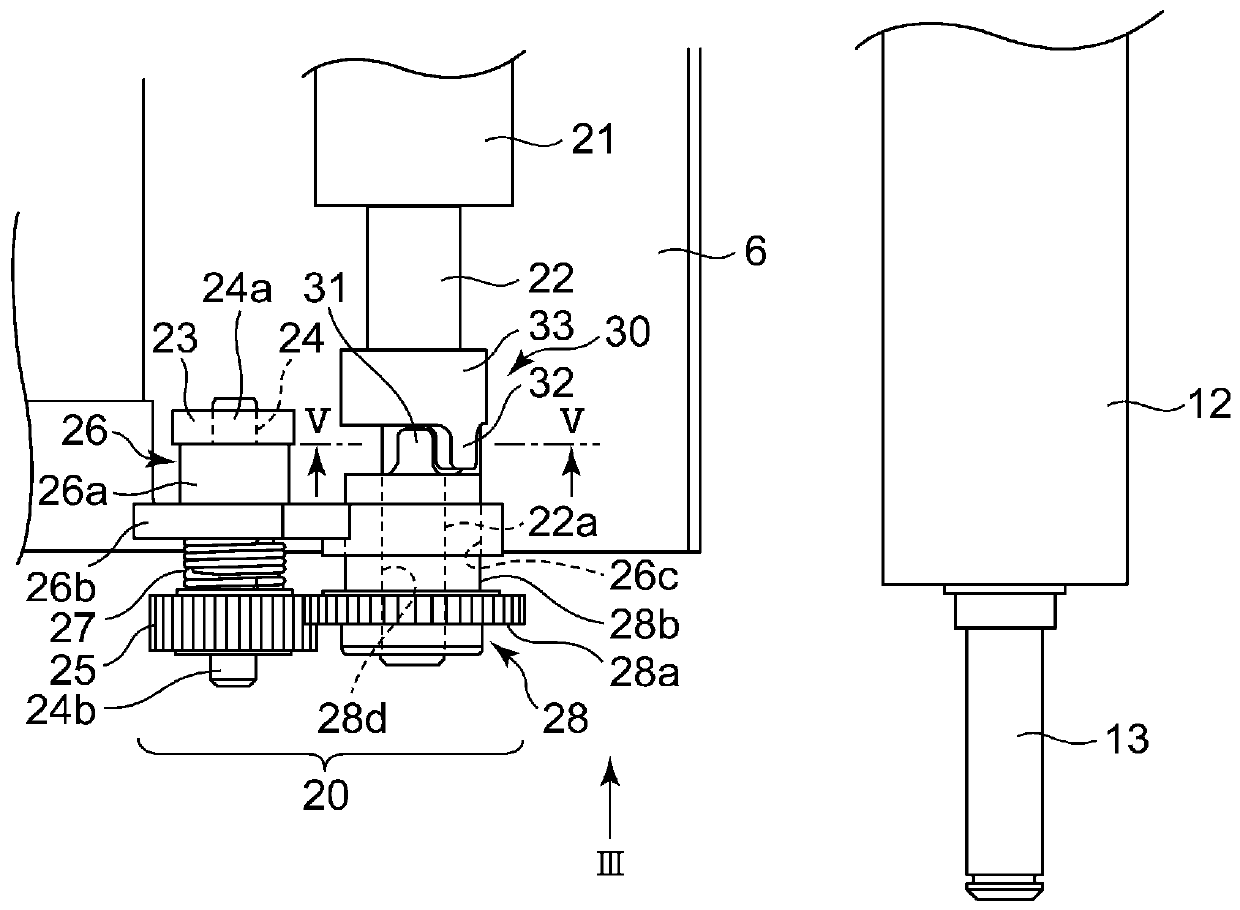

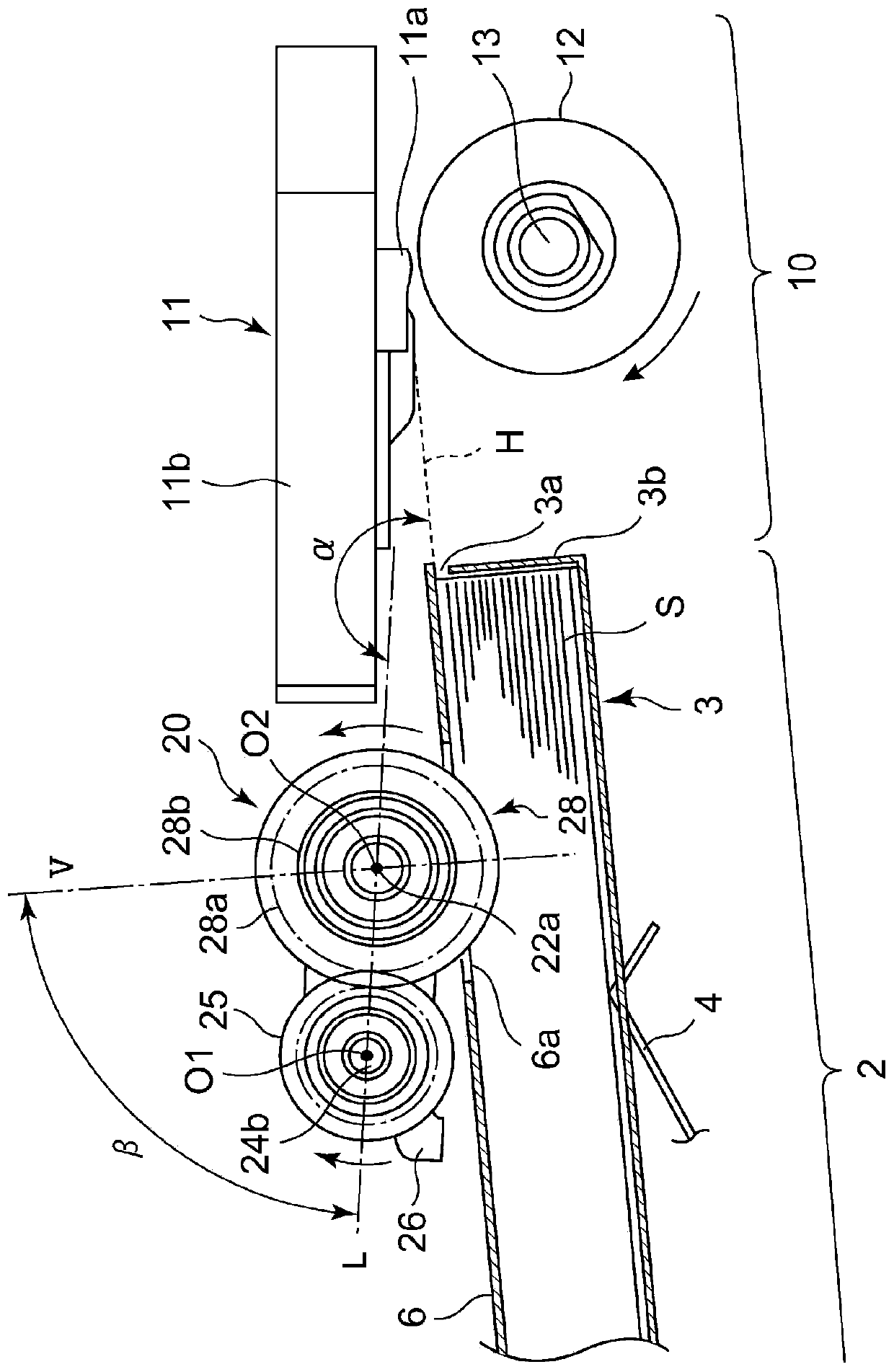

[0067] figure 1 It is a top view of the image forming apparatus 1. In the image forming apparatus 1, the paper setting section 2 and the image forming section 10 are arranged side by side, and are small and thin as a whole. The delivery mechanism section 20 is arranged to overlap the image forming section 10.

[0068] Such as image 3 with Figure 4 As shown, the paper feeding cassette 3 is installed in the paper setting part 2. One or more sheets of paper S are set (stored) inside the paper feed cassette 3. The paper setting part 2 is provided with an urging member 4 that pushes the paper S in the paper feed cassette 3 upward. in image 3 with Figure 4 In the example shown, the urging member 4 is a leaf spring. A paper feed slit 3a is formed in the upper part of the front of the paper feed cassette 3, and the uppermost paper of the paper S pushed up by the urging member 4 is sent out from the paper feed slit 3a.

[0069] In the image forming section 10, a printing member 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com