Disassembly-prevention fastener

A fastener and anti-disassembly technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve problems such as increasing the difficulty of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

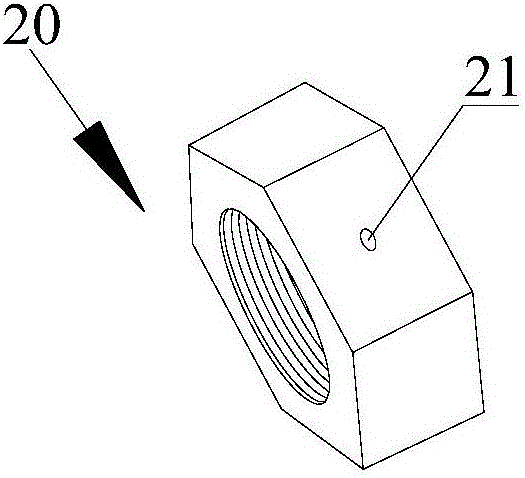

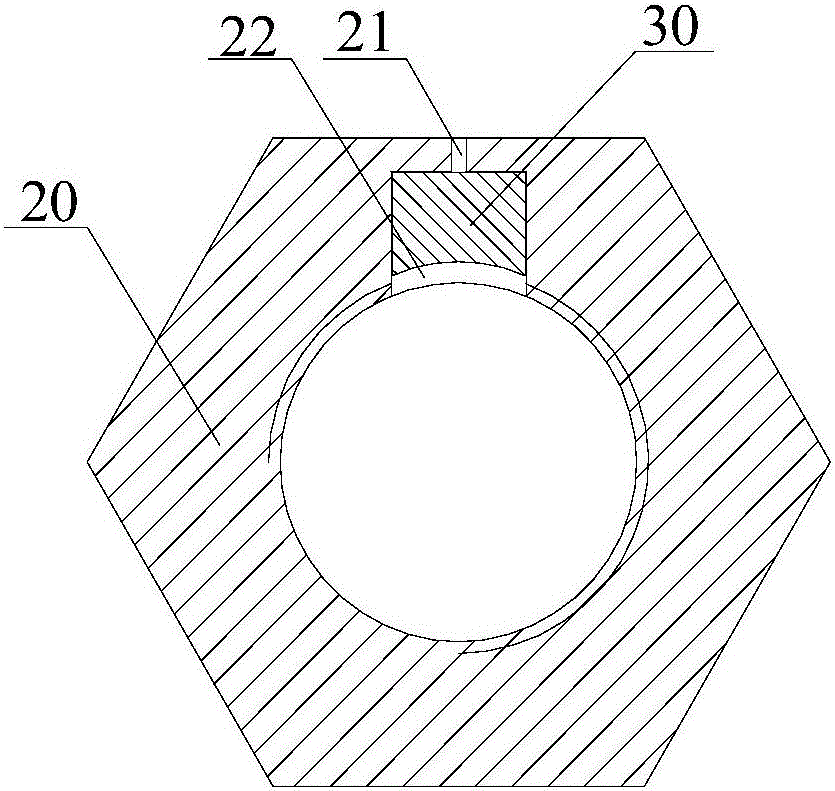

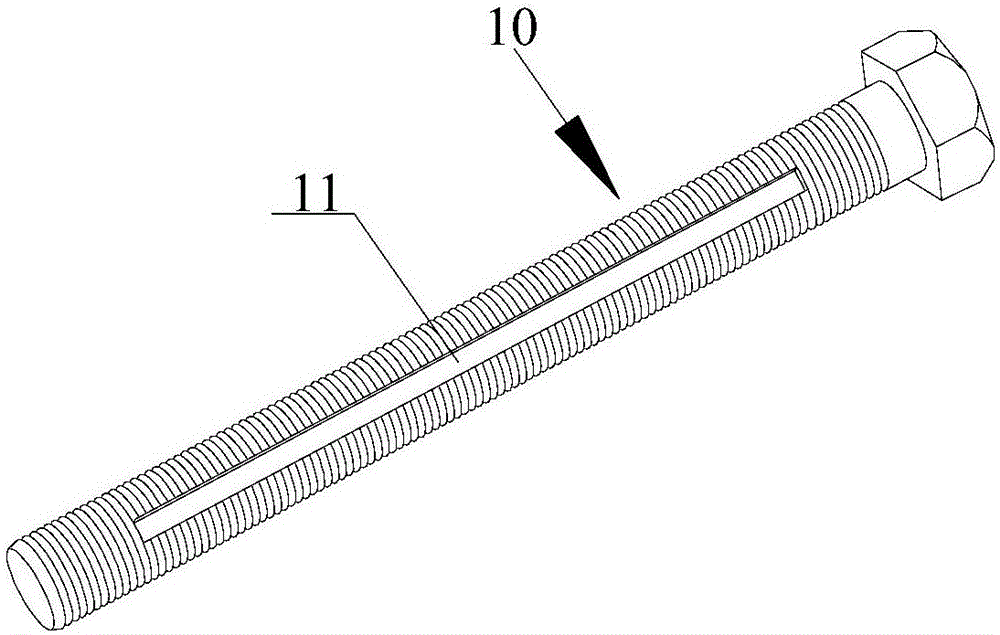

[0016] Anti-tamper fasteners such as figure 1 — image 3 As shown, it includes a bolt 10 and a nut 20. The bolt 10 has a groove 11 along its length, and the nut 20 has a cavity 22 for accommodating the locking block 30. The width of the cavity 22 is the same as the width of the groove 11. Similarly, the bottom of the cavity 22 communicates with the threaded hole of the nut 20, and a through hole 21 runs through the top of the cavity 22 and the outer wall of the nut 20. A locking block 30 is arranged in the cavity 22, and the locking block 30 is connected to the inner wall of the cavity 22. In a transitional fit, the vertical height of the locking block 30 is smaller than the depth of the concave cavity 22 and larger than the depth of the groove 11 .

[0017] When in use, make the groove 11 of the bolt 10 and the concave cavity 22 of the nut 20 position opposite, insert in the through hole 21 with a round stick, and the bottom end of the round stick is against the locking bloc...

Embodiment 2

[0019] Anti-tamper fasteners such as figure 1 , Figure 4 and Figure 5 As shown, it includes a bolt 10 and a nut 20, and the material of the bolt 10 and the nut 20 is iron. The bolt 10 has four grooves 11 along its length, and the nut 20 has a cavity for accommodating the locking block 30. 22. The width of the cavity 22 is the same as the width of the groove 11. The bottom of the cavity 22 communicates with the threaded hole of the nut 20. There is a through hole 21 running through the top of the cavity 22 and the outer wall of the nut 20. The cavity 22 is provided with a lock Block 30, the material of the locking block 30 is a magnet, the locking block 30 is adsorbed in the concave cavity 22, the vertical height of the locking block 30 is less than the depth of the concave cavity 22 and greater than the depth of the groove 11, the locking block 30 There is also a threaded hole 31 on the surface, the threaded hole 31 corresponds to the position of the through hole 21 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com